High Quality Extensible PVC Geogrids for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

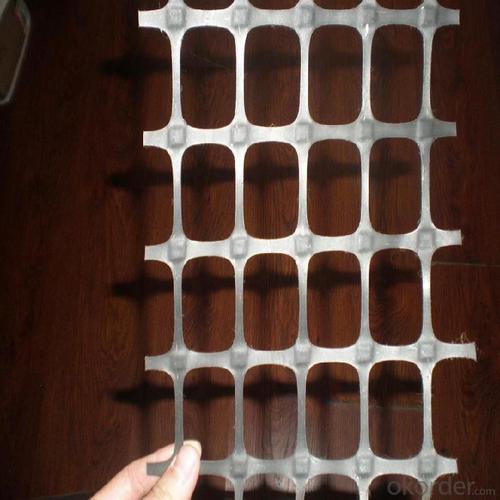

Structure of Pvc Geogrid

Black PP Geogrid is a kind of high --tensile strength geosynthetic material in the road construction and reinforcement,can be applied in enhancing the highways, municipal roads, railways, runways and other subgrade enhancement.

Main Features of the Pvc Geogrid

fiberglass geogrids

Corrosion resistance, no long-term creep, long life span.

Good physical and chemical stability and good thermal stability.

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Pvc Geogrid Images

Pvc Geogrid Specification

Roadbed reinforcement of road and railway,crack prevention,increase of roadbed strength;

Reinforcement and stabilization of riverside,embankment and side slope;

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

Reinforcement of soft soil foundation and overall strength of roadbed

| Specification | EGA30-30 | EGA50-50 | EGA80-80 | EGA100-100 | EGA120-120 | ||

| Mesh size(mm) | 25.4×25.4or12.5×12.5 | ||||||

| Breaking strength≥(KN/m) | Warpdirection | 30 | 50 | 80 | 100 | 120 | |

| Across warp | 30 | 50 | 80 | 100 | 120 | ||

| Elongation at break≤(%) | Warp direction | 3 | |||||

| Across warp | 3 | ||||||

| Elasticity modulus(GPA) | 67 | ||||||

| Thermal tolerance() | -100~280 | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Biaxial Plastic Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in soil reinforcement for oil and gas pipeline projects?

- Yes, geogrids can be used in soil reinforcement for oil and gas pipeline projects. Geogrids are often employed in this context to provide stabilization and reinforcement to the soil, improving its load-bearing capacity and preventing soil erosion. This helps ensure the integrity and longevity of the pipeline system, making geogrids a valuable solution for soil reinforcement in oil and gas pipeline projects.

- Q: Do geogrids affect the permeability of soil?

- Yes, geogrids can affect the permeability of soil. Geogrids are typically used in civil engineering to reinforce soil and increase its strength. When installed, geogrids create a network of interconnected channels that enhance the drainage system within the soil. This improved drainage can result in increased permeability, allowing water to flow more freely through the soil.

- Q: Can geogrids be used in reinforcement of mechanically stabilized slopes?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized slopes. Geogrids are commonly used in such applications to enhance the stability and strength of slopes by providing additional tensile strength and confinement to the soil. This helps to resist lateral forces and prevent slope failures, making geogrids an effective solution for reinforcing mechanically stabilized slopes.

- Q: How do geogrids help in reducing the risk of differential settlement of structures?

- Geogrids help in reducing the risk of differential settlement of structures by providing a stable base and distributing the load more evenly across the soil. This prevents uneven settling and minimizes differential settlement, which can lead to structural damage and instability.

- Q: How do geogrids improve the performance of mechanically stabilized walls?

- Geogrids improve the performance of mechanically stabilized walls by providing reinforcement and enhancing the stability of the wall structure. They act as a support system, increasing the tensile strength of the soil and preventing it from sliding or collapsing. The geogrids distribute the loads exerted on the wall more evenly, reducing the pressure on the wall face and minimizing the risk of structural failure. Additionally, they enhance the overall durability and longevity of the wall system by preventing soil erosion and promoting proper drainage.

- Q: How many Chinese geogrid manufacturers? How many famous

- Manufacturers have more than N, there is no specific how much to say

- Q: Can geogrids be used in slope stabilization for railway cuttings?

- Yes, geogrids can be used in slope stabilization for railway cuttings. Geogrids are commonly employed in civil engineering projects to reinforce soil, provide stability, and prevent erosion. In the case of railway cuttings, geogrids can be used to reinforce the slopes, increase their load-bearing capacity, and minimize the risk of slope failure. By distributing and confining the soil, geogrids enhance the overall stability and longevity of the railway infrastructure.

- Q: What is the tensile strength of geogrids?

- The tensile strength of geogrids can vary depending on the specific type and design, but generally, it ranges from 20 to 200 kilonewtons per meter.

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering projects to improve soil stability and prevent soil erosion. They are effective in providing reinforcement and reducing the potential for soil settlement, making them suitable for enhancing the stability of pipelines in various soil conditions.

- Q: What is the effect of confinement on geogrid performance?

- The effect of confinement on geogrid performance is generally positive. Confinement helps improve the stability and load-bearing capacity of geogrids by restraining lateral movement and enhancing soil-geogrid interaction. It prevents the geogrid from elongating or deforming under heavy loads, leading to better reinforcement and increased structural integrity. Confinement also reduces the potential for geogrids to slip or creep, improving their long-term performance and durability.

Send your message to us

High Quality Extensible PVC Geogrids for Softbed Foundation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords