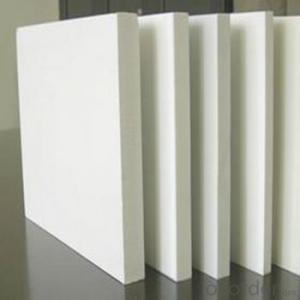

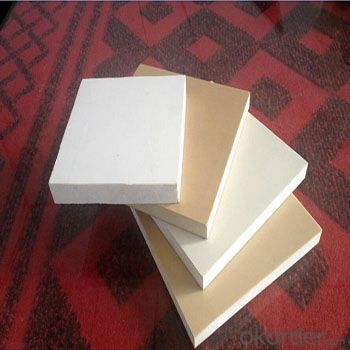

PVC Foam Plastic Sheets for Kitchen and Washroom Cabinets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features:

1. Waterproofing.

2. Heat preservation.

3. Excellent insulated.

4. Non-corrosion.

5. Non-toxic.

6. Light weight.

7. Fire retardant and self-extinguishing.

8. Tough, rigid with the high impact strength.

9. Good plasticity, being an excellent thermoform material.

10. Easy to clean and maintain.

PVC Foam board Specifications

PVC foam board has a consistent cell structure and density from surface to core that performs well in advertising applications. The cell structure makes in the choice for professional printers, sign makers and exhibition contractors.

PVC Foam Board features

1.Non-absorbent, fire retardant and self-extinguishing

2.Water proof, vandal proof, and can be shaped, molded, painted and screen printed

3.Non-corrosive, non-toxic and chemical resistant

4.Tough, rigid with high impact strength

5.Easy to clean and maintain

6.Stable color retention

7.Customization is available: anti-UV, lead free, sound-insulated, etc

PVC Foam Board application

1.Advertising: for signs, billboards, lettering boards, displays, shop-window displays, large letters, exhibition stands, denoters.

2.Building: for shop-fitting, interior decorating, zones of high humidity (e.g. bathrooms), cladding, roller-shutter boxes, door panels, heat and sound insulation, window elements, non-transparent spandrel infill panels, decorative sheets outdoors and indoors, storage racks, room segments.

3.Miscellaneous: for models, furniture industry, thermoforming products, photograph lamination, traffic signs for road works, chemical, laboratory and food sectors, interior decorating materials of buses, trains, etc.

FAQ

,How can I get a sample?

Answer: FREE SAMPLE can be sent to you .Freight will be collect.

Product pictures

Factory Pictures

- Q: I want to buy only the plastic sheet. if the store has online shopping thing thats fine too!

- MicroLens is your best bet. They also have lenses with adhesive on the back. Their website is not much help except it has their phone number, best to call them directly, and ask for the flip software that comes with your first order.

- Q: How long do plastic sheets last?

- The lifespan of plastic sheets can vary depending on various factors such as the type of plastic, its quality, usage conditions, and maintenance. Generally, high-quality plastic sheets can last for several years or even decades if properly cared for and not exposed to harsh conditions.

- Q: Are plastic sheets food safe?

- Yes, plastic sheets can be food safe depending on the specific type of plastic used. Certain food-grade plastics, such as those that meet FDA regulations, are designed to be safe for contact with food and are commonly used in food packaging and preparation. However, it is important to ensure that the plastic sheets you are using are specifically labeled as food safe to guarantee their suitability for storing or handling food.

- Q: What are the advantages of plastic sheets?

- Plastic sheets offer several advantages including durability, versatility, and cost-effectiveness. They are lightweight yet strong, making them resistant to impact and weather conditions. Plastic sheets can be easily molded into various shapes and sizes, making them suitable for a wide range of applications. Additionally, they are affordable and require minimal maintenance, making them a cost-effective choice for many industries.

- Q: Can plastic sheets be used for insulation against sound or vibrations?

- Yes, plastic sheets can be used for insulation against sound or vibrations. They can help dampen vibrations and reduce the transmission of sound, making them a viable option for soundproofing applications.

- Q: What's the name of the perforated plastic board for one board?

- Plastic plate: plastic plate made of plastic sheet with high plastic compound free to change the form of plastic raw materials using monomer or condensation reaction of polymeric materials by resin and fillers, plasticizers, stabilizers, lubricants, additives such as pigment group chelating resin

- Q: What are the common uses for plastic sheets?

- Plastic sheets have a wide range of common uses. They are commonly used for packaging materials, such as bags and films, as well as for protective coverings. Plastic sheets are used in construction for weatherproofing and insulation purposes, and they are also utilized in the manufacturing of various consumer goods like toys, furniture, and electronic components. Additionally, plastic sheets are popular in the signage industry for creating durable, lightweight, and versatile signs.

- Q: Can plastic sheets be used for architectural models?

- Yes, plastic sheets can be used for architectural models. They are commonly used due to their versatility, durability, and ease of shaping. Plastic sheets can be easily cut, bent, and formed into various architectural elements, making them ideal for creating detailed and accurate models of buildings and structures.

- Q: How can I remove the glass glue from the plastic?

- Acetone. Method ibid. Less and thoroughly, and best of all, it removes the residual gum quickly, easily, and more efficiently than the essence. All two of these are solvents and are the best in all methods.

- Q: How many kinds of materials are extruded polystyrene foam boards?

- It is made from polystyrene resin as raw material and other raw materials and polymer content, by heating mixed with catalyst, rigid foam board and plastic extrusion molding and manufacturing. Its scientific name is insulatedwith extruded polystyrene foam (XPS), XPS has a closed cell cellular structure perfect, this structure allows the XPS board a rather low water absorption (almost no water absorption), low thermal conductivity, high compressive strength, ageing resistance (normal use almost no aging decomposition phenomenon).

Send your message to us

PVC Foam Plastic Sheets for Kitchen and Washroom Cabinets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords