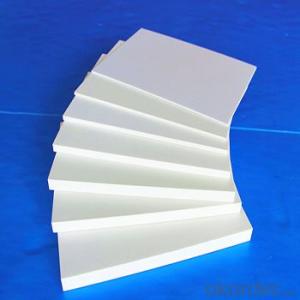

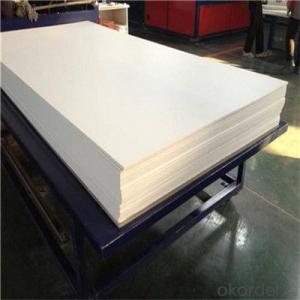

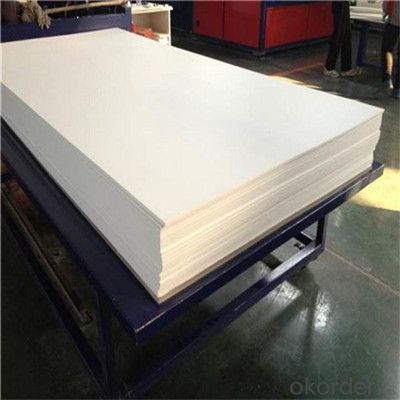

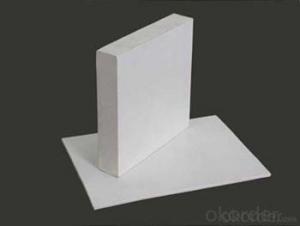

Plastic Sheets - Good Quality Waterproof PVC Foam Board for Kitchen Cabinet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Features

1. Light weight, easy and convenient to storage, transportation and use

2. It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

3. Uniform fine & close cell structure

4. Hygienic, Rigidity, Durable

5. Perfect chemical corrosion resistance, good resistance to UV & weathering

6. Fire retardant and self extinguishing

7. Moisture-resistant, mildew proof, rot proof, low water absorption

8. Non-deformation, color fastness for a very long time

9. Sound insulation, sound absorption, heat insulation and heat preservation

10. Easily to put protective film on one or two sides

11. Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

2.Applications

1. Advertising Signs, billboards, displays, exhibition stands

2. Screen printing, laser engraving

3. Thermoformed parts

4. Architecture, indoor and outdoor decoration

5. Furniture, kitchen & bathroom cabinet

6. Walls & partitions, wall cladding

7. Poolside furniture, swimming pool floor planking

8. Board for Chemical industry and laboratory equipment

9. Interior scaleboard for boat & ship, vehicle, train

3.Processing Properties

PVC Foam Board//PVC Celuka Board//PVC Foam Sheet//Solid PVC Board has same processing methods as wood, such as cutting,sawing, digging, opening holes, nailing, screwing, adhering, and also has the processing methods with thermal bonding and plastic welding which is more superior than wood.

4.photo

- Q: also...what kind of glue would i need to glue it to the bottom of a skimboard?

- would be counted on the plastic, besides the undeniable fact that laminate sheets could somewhat generally soften. maximum laser printer have fuser temperatures at or around 400F, so maximum effective plastics specifically made for laser printers will ought to be used.

- Q: Can plastic sheets be used for cutting boards?

- No, plastic sheets are not recommended to be used as cutting boards because they can be easily scratched and damaged, providing a breeding ground for bacteria. It is best to use cutting boards specifically designed for food preparation, which are usually made of durable materials such as wood or food-grade plastic.

- Q: What's the arc plastic board on the wheel?

- According to the installation position can be divided into a front wing and rear wing and front fender mounted on the front, must ensure that the rotation of the front wheel and beating the maximum limit space, so the designer will be selected according to the type of tyre size "wheel bounce map" to verify the design size of the wing is appropriate.

- Q: What are the requirements for plastic channel plate routing?

- Plastic board for dry field cooperation permanent wire laying groove plate wiring should be in the civil plastering dry after appearing, be close to the surface of the buildings to be flat vertical.

- Q: even if i take him on a walk he will pee on the plastic bags. and also when were gone he lays on the table and stands there on the table. why?

- If he's not already, have him fixed....

- Q: PVC how dirty is the plastic board? Can it be cleaned soon?

- Wipe with a clean cloth, with a little acetone, once passed. You try, we are all so tall

- Q: something thin to make cut-out necklaces from?

- You don't say how thick. In general, plexiglass (which uses a watery catalyst bonder that is instant) has to be bought in 4 foot by 8 foot sheets and is fairly expensive. You find that in companies that make custom displays for stores and conventions. The wholesalers will not sell to the public. If you want thin, paper thickness, try a blueprint house that sells supplies.

- Q: What types of plastics are used to make plastic sheets?

- There are various types of plastics used to make plastic sheets, including polycarbonate, acrylic, polyethylene, and polypropylene.

- Q: Which is better, the aluminum pinch plate and the PVC pinch plate?

- 1, as the smoothness of the plastic aluminum buckle buckle, plastic buckle installation is complex, installation requirements, poor planeness, seam as steel.2, the aluminum gusset plate type, the design does not have the plastic steel many, the aluminum gusset plate mainly takes the metal as the raw material, therefore the price is higher.3, aluminum pinch plate quality difference is big, aluminum gusset plate is also divided into three levels: the first kind of aluminum alloy plate, aluminum manganese alloy plate, aluminum magnesium alloy plate. Among them, the oxidation resistance of Al Mg alloy plate is the strongest.

- Q: Can plastic sheets be used for interior design applications?

- Yes, plastic sheets can be used for interior design applications. Plastic sheets offer a wide range of design possibilities, as they come in various colors, patterns, and textures. They can be used for wall cladding, ceiling panels, room dividers, furniture, and other decorative elements. Additionally, plastic sheets are durable, easy to clean, and cost-effective, making them a popular choice for interior designers.

Send your message to us

Plastic Sheets - Good Quality Waterproof PVC Foam Board for Kitchen Cabinet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords