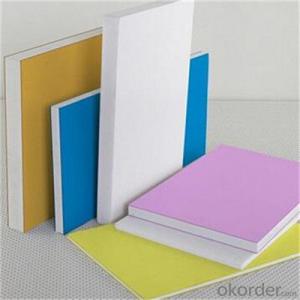

Plastic Sheets - PVC Foam Sheet for Kitchen or Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Name | Density(g/cm3)±0.02 | width and length(mm) | Thickness(mm)±0.2 | Color |

PVC Foam Board | 0.8 | 1220*2440 | 1~25 | white,red, yellow, blue, green, gray, black |

0.6 | 2~25 | |||

0.5 | 2~25 | |||

0.8 | 1560*3050 | 1~10 | ||

0.6 | 2~10 | |||

0.7 | 2050*3050 | 1~10 | ||

pvc rigid sheet | 1.36-1.45 | 1220*2440 | 0.23-1.8 | |

2-5.8 |

Features:

1. feather light, non-absorb water, fire retardant and self-extinguishing

2. sound insulation, heat insulation , noise absorption, heat preservation and corrosion preventin.

3. weather proof, vandal proof, and can be shaped, moulded, painted and screen printed.

4. non-warping and stain proof.

5. non-corrosive, non-toxic and chemical resistant.

6. tough, rigid with a high impact stregth.

7. easy to clean and maintain.

Application:

1.Advertisement: exhibition & display,digital printing,silk screen printing,engraving materials,sign board, etc.

2.Furnitureoffice furniture,cabinet,bath cabinet,etc.

3.Finishing Materialdecorative sheets,storage racks,room segments,etc.

4.Industrial Application:thermoforming products,refrigeratory warehouse project,environmental protection.

Purpose:

PVC foam can be Advertising solvent printing ,display plate ,silk-screen, computer lettering, sign plate , lightbox ,inner & out decorating panel ,commercial decorating shelf ,room separating panel roof decorating panel and other industry

Advantage: Light rough high intensity heat preservation & insulation ,damp &water proof Anti-mildew& rot , acid & alkali endurable ,sound insulation & absorbing insulated Apyrous damping aging prevention .Hot moulding and fabricated with other PVC material are available. Well fit sticked printing design pressed , paint and other fabrication.

FAQ:

Q: What's the PVC Foam Sheet Features?

A: 1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Picture of Our Products:

- Q: With what glue can you stick glass and plastic board firmly?

- Room temperature (25 DEG C) the adherend processing clean, then the material mixed with the ratio of 1:1 with visual glue and B glue coated A after 3 minutes to be coated on the surface of the adhesive, fixed 5-10 minutes positioning.

- Q: Are plastic sheets resistant to warping or bending with heavy loads?

- Yes, plastic sheets are generally resistant to warping or bending under heavy loads, as they have a high tensile strength and are designed to maintain their shape and structural integrity even when subjected to significant pressure or weight.

- Q: Can plastic sheets be used for sound barriers?

- Yes, plastic sheets can be used for sound barriers. They are often used in construction projects or industrial settings to reduce noise transmission. Plastic sheets, such as acrylic or polycarbonate, can effectively block or absorb sound waves, making them a suitable material for soundproofing applications.

- Q: in one of the simpsons episodes bart trys to buy a plastic sheet of scratchy that they use to make the cartoons. it ends up just being scratchys arm. what are those plastic sheets called again?

- It is actually spelled, cel, with one L.

- Q: plastic sheet as in like for lamination, with the transparent sheets... PLEASE REPLY!!

- IT WILL MELT unless is for laser printers

- Q: those plastic sheets that can be usd in picture frames, on the shed or in the house, I have seen them in BQ, what shall i type when searching for the plastic sheet on 'OKorder', I have typed plastic sheets but no luck, can you help me on this one.

- If they are the ones I think they are polycarbonate but they are usually in the building section out the back

- Q: Can plastic sheets be used for outdoor signs?

- Yes, plastic sheets can be used for outdoor signs. They are durable, weather-resistant, and can withstand exposure to sunlight, rain, and other environmental elements. Plastic sheets such as PVC and acrylic are commonly used for outdoor signage due to their versatility and long-lasting properties.

- Q: Thanks you guys! You're always so smart!

- It depends on whether this is a mathematics question or a real one that involves actually doing the work. If it's math, then you would cut the piece into 96 1/8 strips and then chop them into 16 3/4 pieces or vice versa, it doesn't matter which you do first. 96 x 16 = 1536. There are 8 strips 1/8 wide in each inch and there are 12 inches in your sheet so 8 x 12 = 96. 12 divided by 3/4 = 16. 96 x 16 = 1536. If this is a real activity, then it depends on the type of plastic you're using and whether you can cut it with a knife or paper cutter because if it's plexiglass you have to use a saw of some sort and you can lose up to 1/8 for each cut due to the teeth of the saw blade. Therefore you would have approximately half as many finished pieces, and you would probably lose half of those because they'd fly all over the shop. Plexiglas is also prone to static electricity and would attract all the dust in the environment and be kind of a beast to do without special acrylic blades. Thin sheets of film could be done with scissors or a paper cutter.

- Q: Can plastic sheets be used for protective packaging?

- Yes, plastic sheets can be used for protective packaging. They offer flexibility, durability, and resistance to moisture and impact, making them suitable for various applications such as wrapping, cushioning, and securing items during transportation or storage.

- Q: How are plastic sheets different from other materials like glass or metal?

- Plastic sheets differ from materials like glass or metal primarily due to their composition and properties. Unlike glass, which is made from silica and metal, which is derived from various elements, plastic sheets are made from synthetic polymers derived from petroleum or natural gas. This difference in composition gives plastic sheets their unique characteristics such as flexibility, lightness, and resistance to impacts and weathering. Plastic sheets are also more cost-effective to produce and easier to shape and mold compared to glass or metal, making them widely used in various industries.

Send your message to us

Plastic Sheets - PVC Foam Sheet for Kitchen or Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords