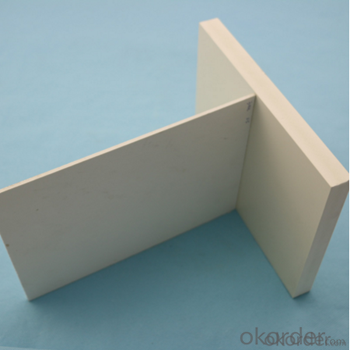

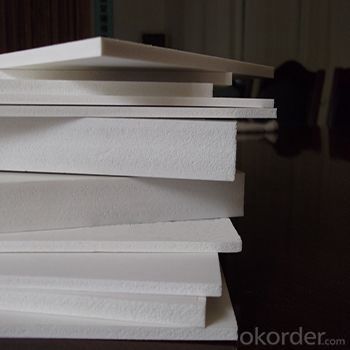

Plastic Sheets - PVC Foam Sheet Tough Rigid with High Impact Strength

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

We are specialized in manufacturing PVC foam board.

Standard Size We Provide as below:

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Marked uniqueness:

1. Lighter weight, better tenacity, and higher rigidity

2. Fireproof, waterproof, mould proof, sound proof, and flame retardant

3. Better insulation, thermal insulation,

4. No sopping, no deformation

5. Easier to clean and process

6. Better plasticity, super thermoform material

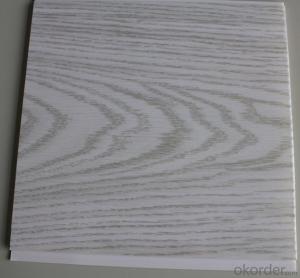

7. Sub-light surface and elegant vision

8. Anti-chemical corrosion

9. Suitable to silk screen printing

10. with imported dyes, unfading and anti-aging

12. Higher surface hardness and lighter texture

13. Optimal substitution for wooden boards in furniture industry

14. be able to cut, saw, weld, glue, thermal forming, nail, plane, caving forming.

15. Uniform foam holes, non-toxic and odorless, smoother surface and brilliant colors.

PVC is a thermoplastic resin that is one of the most widely used plastics in the world. Poly vinyl chloride or abbreviated to PVC is a high volume commodity thermoplastic material which has a very wide application base from medical to window frame.

FAQ

QI:What are manufacturing process is used to make RAJVI PVC foam board?

A1:RAJVI PVC foam board/sheet is manufactured using Co-Extrusion computer based technology, in pvc foam sheet/board manufacturing process three difference processes used Celluka, co-extrusion and Free Foam of PVC foam board to meet different applications' needs..

Q2:What surfaces can RAJVI PVC FOAM SHEET/BOARD be attached to?

A2:Plaster, stucco, vinyl, brick, concrete or wood. Our SHEET/BOARD can be attached to any of the above surfaces.

- Q: OK, I have to do some landscaping and I want to try to prevent weeds from popping up, so I planted 10 Lantana and around the whole area I laid a clear plastic drop cloth, I cut about 12 inch holes for each of the lantana and I covered the whole thing with mulch. I want to make sure that this will not kill the lantana, the plastic does not let water or air through however like I said I cut 12 inch openings for the plants, is this adequate?

- You might get by with it if you water properly. It would have been better to use porous heavy duty landscape fabric.

- Q: I want to renovate my basement, but as I was walking through my local hardware store, I noticed a variety of sheetrock that are mold resistant to fire resistent and at different thicknesses. Is a thicker board better for the basement?Also, is there a way to test moisture in a basement over sheetrock or would I have to remove the sheetrock and apply a plastic sheet with tape to test for moisture?thanks!

- You should really use mold retardant sheetrock in the basement. It might actually be required by code depending on where you live. I helped a guy fix up a house and the inspector told him to sheetrock the ceiling of the basement and use 1/2 mold resistant sheetrock. The differences you get with thickness of sheetrock is mostly durability. Obviously thicker sheetrock will hold up longer. On ceilings especially, the 3/8 inch sheetrock will bend over time between the rafters (or floor joists in the basement) where it is screwed in. There is also a difference in sound-proofing, you hear less through walls of 5/8 than 3/8. The last difference is fire resistance, 5/8 inch sheetrock takes significantly longer for fire to burn through than 3/8. To chose which one you want to use, find out what the code requires in your area. You may be required to use mold resistant sheetrock, or you may be required to use fire resistant boards. I would use 1/2 in the basement because it is a lot easier to hang than 5/8 and you have decent durability and unlike 3/8, it will not bend or bow over time. I actually saw mold resistant fiber tape for the joints in The Home Depot, you might want to use that whether or not it's required by code just for extra measure. Some things may be more expensive to do to the tee, but if you cheap out now, you may end up pending more fixing things if they go wrong or get messed up later down the road. And most importantly, do every single thing to code and pull permits for everything, that way you are covered on all your bases.

- Q: why do people put plastic sheeting down before pouring concrete? I think i know but want to here from experts.?

- Laying Down Concrete

- Q: We are doing a classroom simulation and want to build a space shuttle out of PVC pipe and connectors, and black and white plastic sheeting. The students sit inside at the controls. I have seen mockups made from 2 liter pop bottles but this is not that. I saw one at the science teachers convention in San Diego in 2002 but cannot seem to find the directions on how to build my own.

- Can you contact the organisers of the convention and get the list of teachers who made this type of model? Perhaps someone has on old program or list of booths at the convention.

- Q: Can plastic sheets be used for room divider partitions?

- Yes, plastic sheets can be used for room divider partitions. They are lightweight, versatile, and easy to install. Additionally, plastic sheets offer various colors, textures, and transparency levels to suit different design preferences and privacy needs.

- Q: Transparent plastic board yellowing, how to restore just bought?

- These yellow transparent plastic is not only superficial, but its deep layer has become yellow. What's more, it doesn't have the softness at the beginning and becomes more and more stiff.

- Q: Can I silkscreen grafix to ABS plastic? On the haircell textured side?

- DO the usual, silkscreen to vinyl then overlay it on the plastic.

- Q: Are plastic sheets resistant to solvents or oils?

- Yes, plastic sheets are generally resistant to solvents and oils.

- Q: How can I remove the glass glue on the aluminum plate?

- Because the aluminum plate has a coating film outside the aluminum plate, so the solidified glass glue can not be scraped with the scraper of iron (so as not to hurt the paint film and damage the outer surface of the aluminum-plastic plate).

- Q: Put drops of water on glass or plastic sheet. After evaporation we see white soft dust there. What's that?

- If it was pure water, and there was no dust present in the room there should be no dust. But if it's tap water that is most likely lime deposits or deposits from the minerals in the water. Try the same experiment with distilled water (not bottled drinking water, because minerals are added).

Send your message to us

Plastic Sheets - PVC Foam Sheet Tough Rigid with High Impact Strength

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords