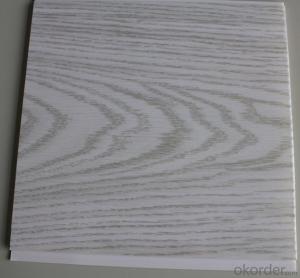

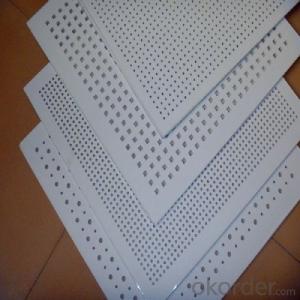

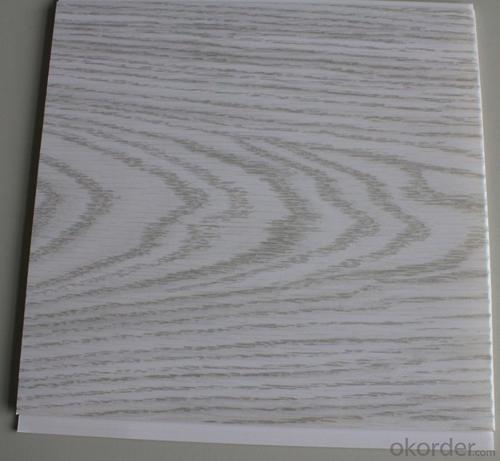

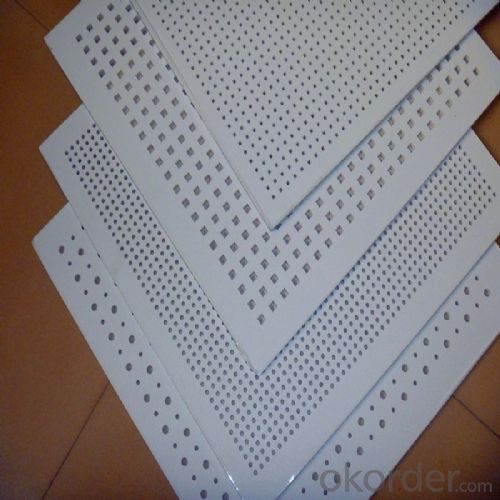

Plastic Sheets - PVC Foam Sheet Tough, Rigid with High Impact Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We are specialized in manufacturing PVC foam board.

Standard Size We Provide as below:

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Applications :

-Advertising Signs

-Displays

-Exhibition Stands

-Point of Sale

-Interior Designs

-Bathroom Fittings

-Models & Prototypes

-Panels & Cabins

-Embossing & Engraving

-Thermoforming

-Lumber

-Trimboard

PVC is a thermoplastic resin that is one of the most widely used plastics in the world. Poly vinyl chloride or abbreviated to PVC is a high volume commodity thermoplastic material which has a very wide application base from medical to window frame.

FAQ

QI:What are manufacturing process is used to make RAJVI PVC foam board?

A1:RAJVI PVC foam board/sheet is manufactured using Co-Extrusion computer based technology, in pvc foam sheet/board manufacturing process three difference processes used Celluka, co-extrusion and Free Foam of PVC foam board to meet different applications' needs..

Q2:What surfaces can RAJVI PVC FOAM SHEET/BOARD be attached to?

A2:Plaster, stucco, vinyl, brick, concrete or wood. Our SHEET/BOARD can be attached to any of the above surfaces.

- Q: Are plastic sheets resistant to chemicals used in pools?

- Yes, plastic sheets are typically resistant to chemicals used in pools.

- Q: Can plastic sheets be used for protective barriers in retail settings?

- Yes, plastic sheets can be used as protective barriers in retail settings. They can serve as a transparent barrier between customers and employees, helping to mitigate the spread of germs and providing an added layer of protection.

- Q: I want to build a Darth Vader helmet/mask. Sculpting is no problem, neither is building the vacuum former, but every web link I have found just tells me what kind of plastic to use, not where to buy it.

- Google your own address then Map then Search Nearby and Plastics - Sheet. This should give you places that will sell you many kinds of plastics and will cut down from full sheets (which are 4x8 ft in US) Call them and ask about types and cost. Some specialize. In Dallas Texas, Regal Plastics is one such.

- Q: after buying the motor home i found out that water from the water source in the rv park had been standing under the trailer for a long time. i was planning to move the home so thought this would be resolved but now do not know that i should move or keep this due to what looks like mold on the surface of the black plastic sheeting containing the insulation under the trailer. also, it s there a problem if water gets into the insulation? this is my first experience with a mobile home do not know who to ask. mobile home dealers have not been able to answer my question. please help.

- I can't see why mold on the exterior of the plastic sheeting should be a problem unless there's an enormous amount of it, if it's there because the underneath of the home didn't get enough ventilation. It could be cleaned off, and shouldn't recur if the next place you put it is dry. If water has gotten into the insulation above the plastic, that would worry me. Wet insulation doesn't work, and if the insulation is wet, there might be other water damage in other parts of the home which could be serious, since the water in the insulation most likely flowed down from somewhere. Is the plastic in good shape with minimal tears in it? If there are any tears, look at the insulation through them to see if you can see any evidence of it having been wet. Have a good look with a strong light under there, and you might be able to answer your own question. Also, though the dealers might not be of much help, there is probably someone in the neighbourhood who does repairs on mobiles, and it might be worth getting them to give an opinion.

- Q: What are the different thickness options available for plastic sheets?

- The thickness options available for plastic sheets can vary greatly depending on the specific type of plastic. However, commonly used thickness options for plastic sheets range from 0.5 millimeters to 25 millimeters or more.

- Q: How long do plastic sheets typically last?

- The lifespan of plastic sheets can vary depending on various factors such as the type of plastic used, the quality of the sheet, and the conditions in which it is used. However, on average, plastic sheets can last anywhere from a few years to several decades.

- Q: What are the different surface treatments available for plastic sheets?

- There are several different surface treatments available for plastic sheets, including but not limited to, polishing, sanding, painting, coating, and printing. These treatments can enhance the appearance, durability, and functionality of the plastic sheets, making them suitable for various applications and industries.

- Q: Can plastic sheets be used as barriers?

- Yes, plastic sheets can be used as barriers. They are commonly used in various applications such as construction sites, hospitals, and food establishments to create partitions, protect against dust or contaminants, and provide a physical barrier for safety purposes.

- Q: I have already asked a couple questions about this, and just need to know 2 more things. I know plastic wrap will work, but this is plastic sheet, and is much better,stronger and will still let light in correct? And for a greenhouse, does there need to be a few holes in the walls and roof to let air through, or should it be basically sealed completely? Thanks for any help!

- don't poke or cut hole in plastic, it will make a weak point that will tear. heavy plastic sheeting tears. you do need to vent the house though frame some openings at one peak near top and corresponding hole near bottom on other end. cover both openings with screen or hardware cloth to kep critters out.

- Q: How do I find on the internet a plastic manufacturer that can glue two 1/4 thick sheets of acryllc together?

- Why don't you just get a piece of 1/2 acrylic?

Send your message to us

Plastic Sheets - PVC Foam Sheet Tough, Rigid with High Impact Strength

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords