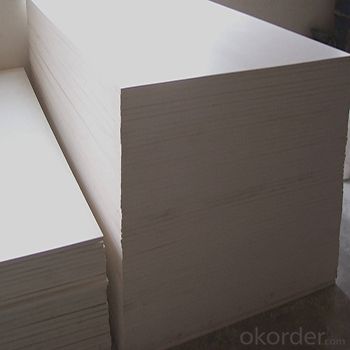

Plastic Sheets - PVC Expansion Sheet, Promotion for PVC Foam Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features:

1. Moistureproof, waterproof, shock absorption and mothproof

2. Fire retardant and self-extinguishing, Heat preservation

3. Sound insulated

4. Insulation

5. Perfect chemical corrosion resistance, good resistance to UV & weathering Non-toxic

6. Non-deformation

7. Non-formaldehyde emission

8. Stable color retention

9. surface is very smooth, rigid and not easy to scratch. Uniform fine & close cell structure

10. same processing as timber, but processing performance is much better than wood

11. Light weight, easy and convenient to storage, transportation and use

Technical data sheet:

| inspection items | unit | standard | standard |

| L-600 | L-1100 | ||

| test results | test resuts | ||

| density | kg/m3 | ≥115 | ≥90 |

| tensile strengh | mpa | ≥1.0 | ≥0.9 |

| beark strength | kg/m2 | ≥6.5 | ≥3.5 |

| compression strengh | kg/m2 | ≥150 | ≥130 |

| permanent distortion at pressure | % | ≥0.9 | ≥0.7 |

| elongation | % | ≥80 | ≥70 |

| water absorption | g/m3 | ≤7 | ≤8 |

Performace of material

1. The product has the same processing performance, can nail, drilling, cutting, bonding, with a nail or bolt connection fixation, smooth surface, no need to sanding and paint, the paint adhesion also according to individual be fond of painting.

2.Better than wood dimensional stability,can be coated or composite colorant surface can be made of brilliant color, so no need to timely maintenance.

3. A variety of specifications, size, shape and thickness of the demand, which also includes a variety of design, color and grain products, provide more choices to customers.

4.The product is fireproof, waterproof, corrosion, resistant to moisture, not moth eaten, non-toxic, no pollution and other excellent performance, low maintenance cost

5 The use of products have similar wooden appearance, high hardness than plastic, long life, thermoplastic molding, high strength, saving energy

6.Light weight, heat preservation, smooth surface, no formaldehyde and other harmful substances, no poison, no pollution

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

- Q: Can plastic sheets be used for shelving?

- Yes, plastic sheets can be used for shelving. They are lightweight, durable, and easy to clean, making them a practical choice for shelving solutions. Additionally, plastic sheets can be easily cut and shaped to fit specific shelving needs.

- Q: Can plastic sheets be molded into different shapes?

- Yes, plastic sheets can be molded into different shapes through processes such as thermoforming or injection molding.

- Q: Can plastic sheets be used for sneeze guards?

- Yes, plastic sheets can be used for sneeze guards. They are often used as a cost-effective and transparent barrier to prevent the spread of germs and droplets in various settings such as restaurants, retail stores, and healthcare facilities.

- Q: I'm looking for sheet music for all and any instruments including the vocal on that song.

- Try okorder

- Q: im after some plastic sheets at least 2mm thick im making me own pet tank for snails if you get me the bigger n better the sheets n cheaper the better do you know any good onlines places to order from

- 2mm is pretty thin. If you don't mind going with 4-6mm, then you can get Acrylic (plexiglass) sheet. If there is a plastics processing company near you, you may be able to get Lexan (Polycarbonate) at a pretty good price. You can find the acrylic sheet at most hardware stores. If you screw the pieces together, make sure you slowly drill pilot holes first or you will crack the edges. Other than that, it pretty easy to work with and very durable.

- Q: We are in the process of building a roof over our concrete 10x10 patio. We have put 2 4x4's on the front two corners and the other edge without 4x4s is attached to the side of the house. We are using 2x6's along the length of it as support along the top and then will top with 1x4's before putting on the roof sheets of our choosing. Our neighbor that has helped us used white plastic looking sheets on his roof of the same design (I believe the brand is tuftex?). When we went into the store the other day I noticed Green Metal Sheets (Tin I believe)... the price difference isn't really an issue but I want it to be decent quality at the same time... any suggestions or comments on the pros and cons of each? Any other ideas?Thanks

- Scotto is right about not using metal in a salt environment, and the noise factor. The last consideration is that metal will absorb more heat from the sun and Polycarbonate or vinyl will keep your patio a bit cooler. Also if you opt for the opaque type you will have more light.

- Q: I have a house in an area (southern Ontario) that is subject to wind-storms. I want to enclose my side porch in plastic so that I can smoke there - I just had a baby and can't smoke inside anymore. I put up 5 mm plastic with staples and strapping wood held up with finishing nails, but in the first wind-storm most of it came down. Would tarps work better? I can't afford to do it in properly with lattice and plywood right now, although that is my ultimate goal. Also I am alone here with my baby, my husband is a long-hauler and I need to be able to do this myself. I can operate a nail gun, a skil-saw, a staplegun. Please advise!

- i'm giggling on the canines answer... nicely ordinary procedures that would desire to paintings are orange peels, line the porch with them. or you may attempt mothballs besides, in spite of the fact that they stink, this deters maximum cats. There rather is not any opposite direction, or maybe those might no longer paintings, as cats are relatively curious, and could do what they want no be counted what. you may call the pound and spot in the event that they're going to come %. up the strays... i'm hoping a number of this facilitates!

- Q: And does this improve stereo sound quality...???

- it's just a moisture barrier. ya! be fine. duct tape to mount iffin you don't have the putty. which you can get a roll of at any auto parts store. re-speakers? the barrier does nothing. nothing short of it's own little enclosure will help those. and that's not always possible. -------- speakers are no better than their enclosures. w/o one, or wrong type, might as well hang it in mid air. but don't let that stop you. it's commonly done in doors. just sayin. i have, if the door skin is close to the magnet, afixed/glued 1/8 thick section of press board to the door skin. as much as it can, cuts down on the influence the door skin *may* have on the magnet.

- Q: What are the features of engineering plastics boards?

- [plastic sheet] refers to the use of engineering plastics made of plates. Among them, industrial plastics is used for industrial parts or shell materials of industrial plastics, is the strength, impact resistance, heat resistance, hardness and aging resistance are excellent plastic. Commonly used five major engineering plastics include: PC, PA, POM, PBT, PPE.

- Q: I'm looking for MINI DVD (3or8cm) carry case, wallet, organizer, plastic insert with 3 binder holes sheets !Can you help me, please ? I just can't find anywere.Thanks a lot.

- try in Bucharest, Muzica shop... or in other places in city...always are...

Send your message to us

Plastic Sheets - PVC Expansion Sheet, Promotion for PVC Foam Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords