Plastic Sheets - PVC Foam Sheet/Board for Advertisement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 1000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

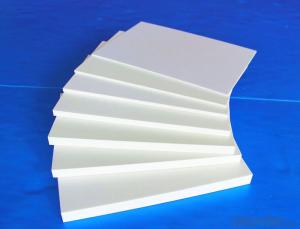

1. Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size:1220mm × 2440mm; 1560mm × 3050mm;2050mm × 3050mm ; or as your request .

Thickness:1-32mm

Production Capacity:10000 pcs per month

Color: White,red ,blue,blace,yellow, as required

Material: PVC

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

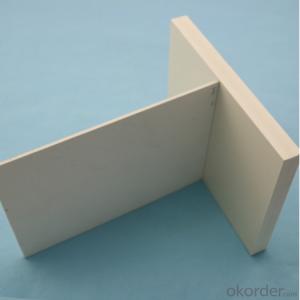

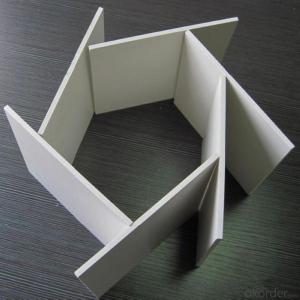

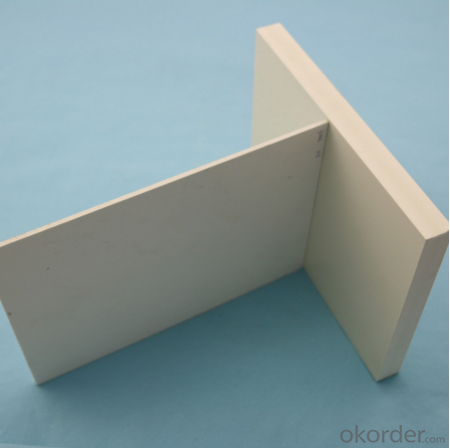

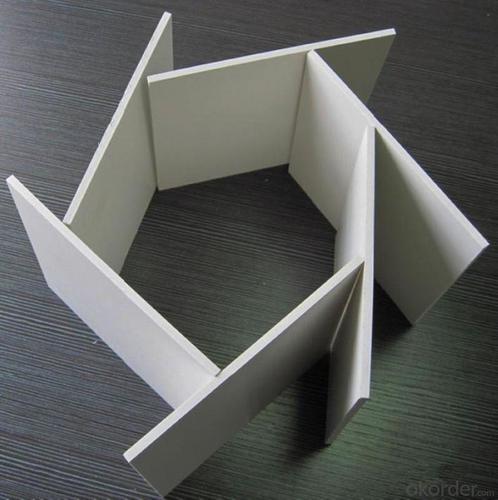

5.Product Pictures

- Q: Can plastic sheets be used for greenhouse insulation?

- Yes, plastic sheets can be used for greenhouse insulation. They are commonly used as a cost-effective option to trap heat and create a controlled environment inside the greenhouse. Plastic sheets can provide insulation by reducing heat loss and preventing cold air from entering the greenhouse, helping to maintain a stable and optimal temperature for plant growth.

- Q: i have a water leak inside my car and its coming from inside the door panel, the plastic inside the door came apart from the metal so the water finds its way inside my car, im wondering what kind of adhesive i can use for this application. i know originally they use a butyl caulk/adhesive tape but idk where to find that stuff, anybody have any ideas?

- excellent answer from dallenmarket, these items are available at an auto body supply specialty shop or a NAPA, Good Luck.

- Q: I got the thick 4mil, does it work better with a space between the window and film? My neighbor puts the film right on the window, does that help? I think a still-air space would work better. How much does it really help, 5%?

- yes the air gap will help because air is an excellent insulator, however, make the gap very small, because if you make it too large then you can get lots of convection(where the air can circulate inside the gap) which will significantly lessen the insulation qualities. This same idea is used in regular fiberglass insulation, the air gaps are created by very small holes in the insulation, and these small holes also help to keep the convection down.

- Q: We are in the process of building a roof over our concrete 10x10 patio. We have put 2 4x4's on the front two corners and the other edge without 4x4s is attached to the side of the house. We are using 2x6's along the length of it as support along the top and then will top with 1x4's before putting on the roof sheets of our choosing. Our neighbor that has helped us used white plastic looking sheets on his roof of the same design (I believe the brand is tuftex?). When we went into the store the other day I noticed Green Metal Sheets (Tin I believe)... the price difference isn't really an issue but I want it to be decent quality at the same time... any suggestions or comments on the pros and cons of each? Any other ideas?Thanks

- Ever listen to raindrops on a tin roof? Its nicer than the pop sounds that plastic make. Tin can also be painted.

- Q: Can plastic sheets be used for protective barriers in healthcare settings?

- Yes, plastic sheets can be used as protective barriers in healthcare settings. They provide a physical barrier to prevent the spread of contaminants, such as droplets or bodily fluids, between healthcare professionals and patients. Additionally, plastic sheets are easy to clean and disinfect, making them a practical choice for healthcare settings where hygiene is crucial.

- Q: Can plastic sheets be used for protective screens in electronic devices?

- Yes, plastic sheets can be used as protective screens in electronic devices.

- Q: I am giving my kitchen cupboards a makeover don't want to paint them so I thought covering them was best any ideas appreciated.thanks in advance

- I looove baking soda. I use it for everything. I sprinkle some over my carpet before vacuuming to get any odors or pet hair out. I sprinkle some in the litter box. I keep an open box in the freezer, the fridge, and all the closets to get rid of odors. And after a couple months I use those boxes to pour down the drain while running hot water. Deodorizes the garbage disposals and is great for unclogging drains. I poor some in the bottom of the garbage cans so there aren't any odors and I poor some into the ash trays outside. I also make a baking soda and water paste and scrub the bathroom top to bottom it works beautifully. I also love vinegar. I use that for my linoleum floors. I mix 1 part vinegar with 4 parts water and my floors sparkle magnificently. I also put 1 cup vinegar and the rest water in my coffee maker and run it to clean that out. I also like to hide dryer sheets under the couch cushions, under the beds, in the vents, in any little place that can't be seen to ensure my home always smells fresh. Also I like to keep one or two used dryer sheets around to use for dusting or to get rid of static in clothes on those windy days. And as far as lamp shades go I like to blow dry them on cold to get rid of any dust particles.

- Q: Can plastic sheets be recycled into new sheets?

- Yes, plastic sheets can be recycled into new sheets through a process known as plastic sheet recycling.

- Q: Are plastic sheets durable?

- Yes, plastic sheets are generally durable. They are designed to be strong and resistant to impact, moisture, and UV radiation. However, the durability may vary depending on the specific type and thickness of the plastic sheet.

- Q: Indoor ceiling plastic how to clean up the most convenient and concise?

- Sponge mop dipped in detergent water, clean up two times.The ceiling is dirty dust and smoke stains, once the water is quickly dissolved, and the plastic buckle resistance, easy cleaning.

Send your message to us

Plastic Sheets - PVC Foam Sheet/Board for Advertisement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 1000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords