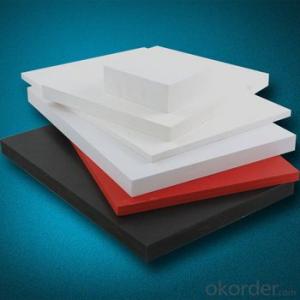

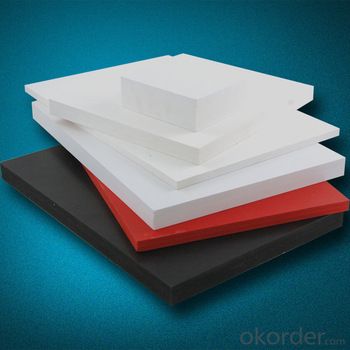

Plastic Sheets - PVC Foam Board/Sheet/Panel 1-33mm PVC Rigid Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Introduction

PVC foam sheet is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

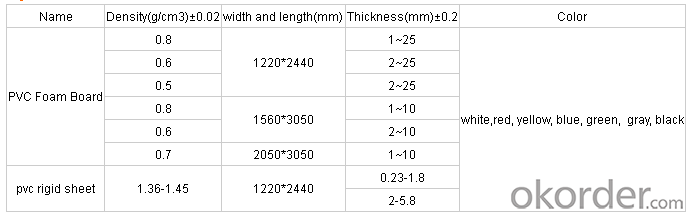

2.Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm,as your request.

Thickness:1-33mm

Density:0.35-0.9

3.Product Features

(1) Light weight, waterproof,

(2)Fire retardant and self-extinguishing

(3) Sound insulation,

(4) Heat insulation,

(5)Noise absorption,

(6)Heat preservation and anti-corrosion.

(7) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(8 Easy to clean and maintain.

(9) Environmental- friendly green and lead-free.

4.Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

5.FAQ

How to get the price?

Please tell me the following information and I'll send you the quotation without delay:

1. size (1220 x 2440 mm or the size you need)

2. thickness (1-33mm)

3. density (0.43mm-0.9mm)

4. quantity

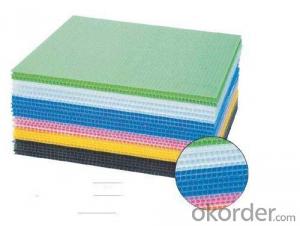

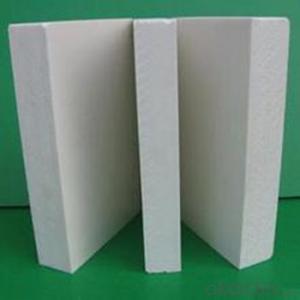

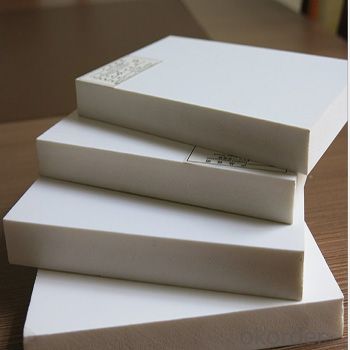

6.Pictures of PVC Foam Sheet

- Q: Can plastic sheets be used for model making?

- Yes, plastic sheets can be used for model making. They are versatile materials that can be easily cut, shaped, and glued to create various components and structures for models. They are commonly used for architectural models, prototypes, and hobby projects.

- Q: Are plastic sheets resistant to punctures?

- Yes, plastic sheets are generally resistant to punctures due to their durable and flexible nature. However, the level of puncture resistance can vary depending on the thickness and type of plastic used.

- Q: I admit I haven’t seen these in years and I'm not sure I’m even using the right term. The only slide shows I’ve seen or made in the past 7 years were Power Point ones.But several years ago I remember these clear plastic sheets that could be printed on with my simple, cheap, disposable printer (a Lexmark that came free with my PC).I have a little 3 in 1 Inkjet (Epson Stylus CX4800) and I want to be able to print on thin sheets of plastic. QUESTIONSDo they still sell those sheets?What are they called?Who sells them?Do you think they would work in an Inkjet or would I need to find someone with a Laser or other type of printer?Thanks

- They are called overhead transparencies like the previous posts say. Make sure you find the one that says for inkjet printers if you are going to use an inkjet. The bad thing is, less and less people are manufacturing them so they are pretty expensive now compared to 4 or 5 years ago. I was shopping for some a few months ago and whoa, the price tripled from before. Anyhow good luck, STAPLES, Office Max, Office Depot. Walmart and Target used to sell em, but not anymore.

- Q: Acrylic plate and plastic plate how to distinguish?

- Acrylic transparent relatively high, but not shock resistance, solvent resistance and other characteristics, compared to plastic plates, from the plate profile of the minor color difference and polishing effect to identify.

- Q: Are plastic sheets resistant to impact?

- Yes, plastic sheets are generally resistant to impact as they are designed to withstand and absorb physical forces without breaking or cracking easily.

- Q: Conservatives, are you not embarrased that you are so easily fooled?

- I made a plastic man, he's got a milk jug for a head. All the left over scraps were recycled. The plastic man keeps the crows out of my tiny herb garden. I had to do something with it since it was never used.

- Q: Can plastic sheets be used for protective screens in electronic devices?

- Yes, plastic sheets can be used for protective screens in electronic devices. They provide a layer of protection against scratches, dust, and other potential damages while allowing users to view the device's screen clearly. Additionally, plastic sheets are often cost-effective and easily replaceable, making them a popular choice for protective screens in electronic devices.

- Q: Can plastic sheets be used for DIY face shields?

- Yes, plastic sheets can be used for DIY face shields. They provide a transparent barrier that helps protect the face from respiratory droplets and other contaminants. However, it is important to ensure that the plastic sheet used is of sufficient thickness and clarity to provide adequate protection. Additionally, proper sanitization and cleaning of the face shield should be practiced to maintain hygiene.

- Q: Can plastic sheets be painted?

- Yes, plastic sheets can be painted. However, it is important to choose the right type of paint that adheres well to plastic surfaces and to properly prepare the plastic before painting to ensure good adhesion.

- Q: Are plastic sheets suitable for outdoor playsets?

- No, plastic sheets are not suitable for outdoor playsets. They lack the durability and strength required to withstand the outdoor elements and the wear and tear of active play. It is recommended to use materials specifically designed for outdoor use, such as treated wood or weather-resistant plastics, to ensure the safety and longevity of the playset.

Send your message to us

Plastic Sheets - PVC Foam Board/Sheet/Panel 1-33mm PVC Rigid Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords