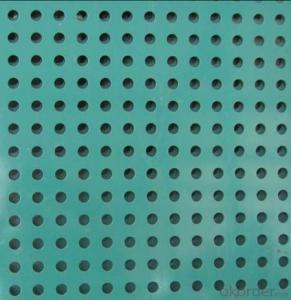

PVC Foam Sheet Decorative Perforated Sheet Metal Panels

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

There are two kinds of PVC Sheet: PVC Foam Sheet and PVC Rigid sheet, and each of them could be cataloged by different producing processes.

They could be used in furniture making such as bathroom and kitchen cabinet or wall cladding , advertising field such as sign board, printing board, indusry field such as the cushion for the heavy machine, etc.

PVC Foam Sheet Application

1) Advertising Signs, billboards, displays, exhibition stands |

2) Screen printing, laser engraving |

3) Thermoformed parts |

4) Architecture, indoor and outdoor decoration |

5) Furniture, kitchen & bathroom cabinet |

6) Walls & partitions, wall cladding |

7) Ceiling boards |

8) Poolside furniture, swimming pool floor planking |

9) Chemical industry and laboratory equipment |

10) Apparatus, container & machine construction |

11) Interior scaleboard for boat & ship, vehicle, train |

Product Specification

Size:1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

Usage Life: more than 50 years

PVC Foam Board Feature:

1. waterproof, fire retardant, acid and alkali, moth, light, heat, noise, vibration characteristics;

2. equal and wood processing, and processing performance is far superior to wood;

3. wood, aluminum, composite board ideal alternative;

PVC Foam Sheet pictures

Packing

FAQ

Q: If the products have some quality problem ,how will you deal with it?

A : If the quality problem caused by us, we will provide a replacement service,and we must keep in mind.

Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q: Could you provide samples?

A: Yes, We provide free samples for customers, but customer shall bear the freight charges or negotiate about this.

- Q: What are the advantages of nylon plates compared to other plastic sheets?

- The nylon series is the most important engineering plastic. The product is widely used, covering almost every area, is the five most widely used engineering plastics varieties Nylon board according to the production process is divided into two kinds of extrusion and casting. Extrude the nylon plate 1, nylon 6 (white): The material has the most comprehensive performance, including mechanical strength, stiffness, toughness, mechanical shock absorption and wear resistance. These features, coupled with good electrical insulation and chemical resistance, make nylon 6 a "universal grade" material for the manufacture of mechanical structural parts and maintainable parts. 2, nylon 66 (cream): Compared with nylon 6, its mechanical strength, stiffness, heat and wear resistance, creep resistance better, but the impact strength and mechanical damping performance degradation, very suitable for automatic lathe Machining. 3, nylon 4.6 (reddish brown): Compared with ordinary nylon, nylon 4.6 is characterized by strong rigid retention, good creep resistance, in a wide temperature range, more heat aging, therefore, nylon 4.6 for Nylon 6, nylon 66, POM and PET in the stiffness, creep resistance, heat aging, fatigue strength and wear resistance can not meet the requirements of the "higher temperature field" (80 -150 ℃) 4, nylon 66 + GF30 (black): Compared with pure nylon 66, this nylon filled with 30% glass fiber reinforced, its heat resistance, strength, stiffness. Creep resistance and dimensional stability, wear resistance and other properties have improved, it is the maximum allowable use of high temperature. 5, nylon 66 + MOS2 (gray black): This nylon filled with molybdenum disulfide, compared with nylon 66, its rigidity, hardness and dimensional stability has improved, but the impact strength has declined, molybdenum disulfide Of the grain formation effect to improve the crystal structure, so that the material bearing and wear resistance are improved.

- Q: What kind of PCB need to use Anti-CAF sheet

- Anti-CAF is a material with special characteristics! In fact, the ordinary FR4 sheet also has enough of this feature, but in the special areas of the product may require more stringent reliability, so the material supplier was the introduction of such a special plate! Electronic migration is mainly a greater impact on the environment, such as humid environment will exacerbate the risk of electronic migration! From the product structure, such as the spacing between the holes is too small, will also cause greater risk!

- Q: Cabinet cabinet board types which

- Plexiglass cabinets In the cabinet looks quite upscale type of plexiglass cabinets, it gives the feeling is quite comfortable, but also easy to clean and durable, but it is more trouble to install, a little problem will be infinite trouble. Such as what the screw interface cracks, stained with oil is difficult to polish shiny and, to beware of plexiglass with the surface friction, high temperature and other extreme conditions (such as accidentally cut the knife tip) and detergent and other strong alkali contact, Produce bad scratches or "rust spots". This is why, the general business that we are three meals a day cooking their own time, do not recommend the use of glass material to do the reasons for the cabinet countertops.

- Q: How is Fuqing plate?

- Environmental aspects: The use of Fuqing Group independent research and development of high-level environmental protection of new plastic, environmental protection level to the highest international F4 star standard and the European E0 standard. F4 star formaldehyde content <0.3mg, E0 level <0.5mg. Truly environmental health.

- Q: What are the types and specifications of wood?

- Divided into: Blockboard, plywood, laminated board, particleboard, MDF, decorative panels, ?1. Blockboard: Blockboard Commonly known as the big core board is made of two pieces of plastic plate from the middle of stamping wood. Blockboard The main specifications for the 2440 * 1220 * 18mm 2440 * 1220 * 15mm 2. Plywood furniture is one of the commonly used materials is a wood-based panel. A group of veneer usually according to the adjacent layer of wood grain direction perpendicular to each other made of sheet metal. The main specifications for the 2440 * 1220 * 3mm 440 * 1220 * 5mm 2440 * 1220 * 9mm 3. Glulam also known as the integration of the same material is the same timber by the lumber processing degreasing, baking dry after the different specifications according to the needs of small pieces of sheet through the finger splicing, the high temperature hot pressing a stereotypes made. The main specifications for the 2440 * 1220 * 12mm 2440 * 1220 * 15mm 2440 * 1220 * 18mm. 4. Particleboard for high-quality wood or small diameter wood after cutting by dry and plastic, made of pressure The main specifications for the 2440 * 1220 * 12mm 2440 * 1220 * 15mm 2440 * 1220 * 18mm. 5 MDF also known as fiber board is wood, tree technology and other objects in the water soaked after the hot mill, pavement, hot pressed from. Common specifications are 2440 * 1220 * 3mm 2440 * 1220 * 5mm 2440 * 1220 * 9mm 6-panel decorative panel is a natural wood or artificial wood cut into a certain thickness of the sheet attached to the surface of the plywood and then hot pressed from a material. Main specifications are 2440 * 1220 * 2.5mm 2440 * 1220 * 2.7mm, 2440 * 1220 * 3.0mm, 2440 * 1220 * 3.6mm 7 melamine board referred to as the full name of melamine is melamine impregnated film paper facing wood-based panel. Main specifications are 2440 * 1220 * 9mm 2440 * 1220 * 12mm 2440 * 1220 * 15mm 2440 * 1220 * 18mm

- Q: What kind of sheet is it ok?

- Computer table material - solid wood. Solid wood computer table to retain the inherent density of wood, toughness, strength and excellent characteristics, with strong and durable, easy to deformation, smooth texture, soft color, elegant and generous characteristics, elegant quality, because solid wood is constantly breathing organism, So need to be placed in the appropriate temperature and humidity environment, suitable for modern office workers. Computer desk material - paint. The main features of the computer table are high brightness, smooth and delicate board, exquisite, stylish, rich colors, suitable for the new era of young people and freelancers. Computer table material - glass. Transparent glass with a combination of metal from the computer desk, unique, the same appearance, different materials, the show will be different temperament and appearance. Glass computer desk with fire, dirt, wear and other characteristics, suitable for modern home and office.

- Q: MD board has no E1 level

- Density Fibreboard by formaldehyde release by E0 level, E1 level, E2 level, P1 level, P2 level. Commonly used in the domestic market density board for the E2 level of environmental protection sheet. Exports of Europe, foreign markets common density board for the E1 level or P2 level, but the E1 grade plate is now no domestic environmental protection certificate. If you want to achieve with the E1 level of environmental protection plate and want to be able to export to foreign countries, you can choose P2, P2 level than the E1 level of environmental protection requirements slightly higher, and can give the relevant environmental certificate.

- Q: Home decoration need to do wardrobe, what plate is the most environmentally friendly?

- Recommend you go to OKorder Long crystal, where the home decoration is very good, especially in the environmental awareness of today's popular people welcome!

- Q: What is the PS board? What is his performance? What is his relevant national standard or industry standard?

- Polystyrene (PS) extruded sheet Features and uses: The product is polystyrene as the main raw material, made by extrusion, free coloring, odorless and tasteless non-toxic, not to bacteria growth, with rigidity, insulation, good printing, etc., mainly for packaging, container equipment, Daily decoration, general electrical and construction and other industries. PS polystyrene decorative board is polystyrene particle molding compound in the extrusion plate on the extrusion molding of organic polymer sheet. Features: PS polystyrene decorative board is a thermoplastic. The specific gravity of 1.05, the melting temperature of 150-180 ℃, the absorption rate is low, light transmission rate of up to 88-92%. Ability to organic acid, alkali, salt and lower alcohols, but also soluble in esters and ketones.

Send your message to us

PVC Foam Sheet Decorative Perforated Sheet Metal Panels

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords