PVC Foam Sheet 15 mm -20 mm Suitable For Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

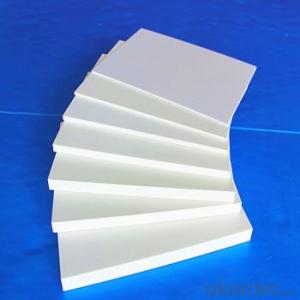

Size : 915*1830 ,1220*2440

Thickness: 1.0-25.0mm

Density:0.45-1.05

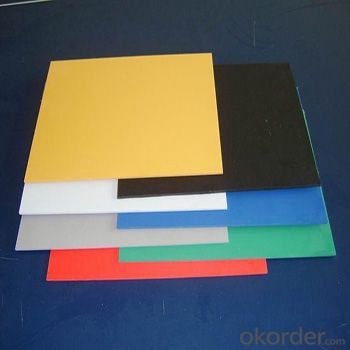

Color : all colors

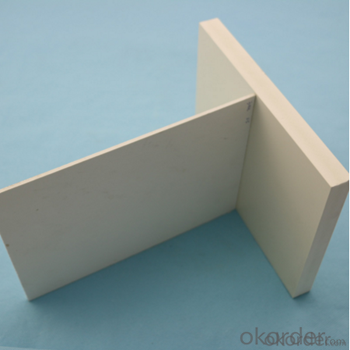

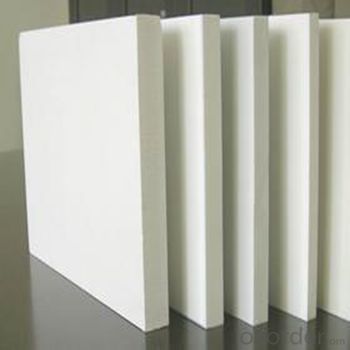

PVC foam board

Specifications

1. Waterproof and mould proof,

2. Widely used in kitchen and washroom cabinet,

3. Thickness from 1mm to 25mm, different density,

We are specialized manufacturing PVC foam board. There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful servise. And now we have 6 production line for PVC foam board

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

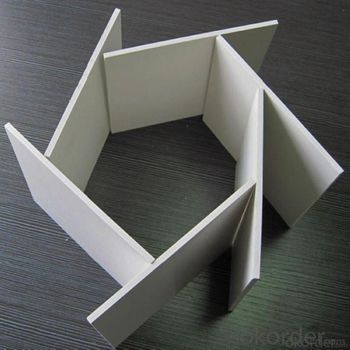

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed.

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house,

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet

Specifications:

1 width: 1220mm.

2 Length: 2440mm or as per your requirement.

3 Thickness: From 1mm to 25mm.

4 Density: From 0.5 to 0.8

Packing details:

PE bag or carton PE BAG packing thickness 16mm, size 1220*2440mm, 500 sheets in one 20 feet container carton packing thickness 16mm, size 1220*2440mm, 420 sheets in one 20 feet container.

Payment: TT, LC

Delivery: 10-15 workingdays after received 30% deposit.

Packing: STANDARD EXPORT PACKING.

FAQ

How to get the price?

A:Please tell me the following information and I'll send you the quotation without delay:

color (white,black,grey,red,blue or other)

thickness (1mm~30mm)

size (1220x2440mm standard,customized is available)

density (0.35-0.80)

quantity(affecting the delivery time

Low Price Excellent chemical and corrosion resistance 3mm pvc foam board.

Product pictures

- Q: These three brands, I would like to know what is the most commonly used models, to prevent follow-up suppliers supply difficulties, so to know the three brands used in the most specific models is what? (Such as Kingboard and the international market, said the material A, in the end what model, not a few people can say clear

- A material is FR-4 plate in the building materials and international materials, the two kinds of materials, high durability, high temperature, toughness than other sheet metal.

- Q: TR-90 cp pc plastic glasses frame difference, as well as what is the material sheet! Physical properties how?

- TR90 spectacle frame surface lubrication, the density of 1.14-1.15, on the saline will float, than other plastic glasses frame light, about half of the weight of the plate material, nylon material is 85%, can reduce the bridge of the nose, the burden of the ear, suitable for young people . It is very resistant to wear, good chemical resistance, solvent resistance, weather resistance is good, not easy to burn, high temperature. And it is memory of the polymer material, anti-deformation index 620kg / cm2, not easy to change because TR90 material Eyeglass frame elasticity, toughness, easy to break, strength, no rupture, so it has sports safety. And it is very resistant to impact: more than 2 times the nylon material, ISO180 / IC:> 125kg / m2 elasticity to effectively prevent In the movement due to impact on the eye damage. No chemical residue release, in line with European food-grade materials requirements. TR90 material than other pc, cp and other frames material is much more expensive, and the production process is also more stringent, so TR90 glasses frame price than the other to be several times more expensive. CP: refers to propionic acid frames PC: refers to the plastic frames, made of polycarbonate Material: The material is made of high-tech plastic memory plate. Ingredients: Most of the current sheet metal components are acetate fiber, there are a few high-grade frame is propionic acid fiber, while the acetate fiber sheet is divided into injection molding and pressing Type, injection molding is the name of the mold is made of water, but most of the current is to suppress the processing of sheet metal glasses in terms of the origin of the plate in France and Italy, the plate is better, Japan is also quite good, many high-end sheet glasses Based on these high-quality sheet, and therefore more reliable quality.

- Q: Are man-made sheets containing formaldehyde?

- Man-made sheet containing formaldehyde: Because the plate, MDF, particleboard, wood flooring and other man-made sheet of formaldehyde mainly produced in the manufacturing process from the bonding of formaldehyde resin. This resin has a strong adhesion, to strengthen the hardness of the board, pest control, anti-corrosion function and cheap, is the first choice for the man-made sheet of raw materials. As the formaldehyde in the floor will not immediately volatilize, but because of different temperature and humidity conditions slowly volatile, volatile time up to ten years.

- Q: What are the types and specifications of wood?

- Divided into: Blockboard, plywood, laminated board, particleboard, MDF, decorative panels, ?1. Blockboard: Blockboard Commonly known as the big core board is made of two pieces of plastic plate from the middle of stamping wood. Blockboard The main specifications for the 2440 * 1220 * 18mm 2440 * 1220 * 15mm 2. Plywood furniture is one of the commonly used materials is a wood-based panel. A group of veneer usually according to the adjacent layer of wood grain direction perpendicular to each other made of sheet metal. The main specifications for the 2440 * 1220 * 3mm 440 * 1220 * 5mm 2440 * 1220 * 9mm 3. Glulam also known as the integration of the same material is the same timber by the lumber processing degreasing, baking dry after the different specifications according to the needs of small pieces of sheet through the finger splicing, the high temperature hot pressing a stereotypes made. The main specifications for the 2440 * 1220 * 12mm 2440 * 1220 * 15mm 2440 * 1220 * 18mm. 4. Particleboard for high-quality wood or small diameter wood after cutting by dry and plastic, made of pressure The main specifications for the 2440 * 1220 * 12mm 2440 * 1220 * 15mm 2440 * 1220 * 18mm. 5 MDF also known as fiber board is wood, tree technology and other objects in the water soaked after the hot mill, pavement, hot pressed from. Common specifications are 2440 * 1220 * 3mm 2440 * 1220 * 5mm 2440 * 1220 * 9mm 6-panel decorative panel is a natural wood or artificial wood cut into a certain thickness of the sheet attached to the surface of the plywood and then hot pressed from a material. Main specifications are 2440 * 1220 * 2.5mm 2440 * 1220 * 2.7mm, 2440 * 1220 * 3.0mm, 2440 * 1220 * 3.6mm 7 melamine board referred to as the full name of melamine is melamine impregnated film paper facing wood-based panel. Main specifications are 2440 * 1220 * 9mm 2440 * 1220 * 12mm 2440 * 1220 * 15mm 2440 * 1220 * 18mm

- Q: Is the quality of the letter sheet?

- Did not hear this brand, only know the top ten brands of plates in the bunny, Moganshan, Yu Fu Lin, the Millennium boat, the king coconut, their product quality certainly no problem!

- Q: In addition to the optical shop can have a special person will help you tune, of course, is generally selling glasses.

- Your glasses should be the kind of plate eyes, right? I also feel that I do not feel the frame is loose, in my case is that the nose is not quite coupled with some of the long legs of the mirror will be a lot of ways, and later found a called "glasses slip sets" Set on the mirror feet will not slide, even if the movement will not slip it ~ My home near the optical shop is to sell a pair of 5 yuan, OKorder also have a lot of color, buy a transparent on the line ~ If the door is not then then consider buying from OKorder, very good, I now learn to bow do not Slipped it

- Q: Stainless steel wire drawing board, polishing plate, mirror the difference between the three

- Stainless steel wire drawing refers to: stainless steel wire drawing is a stainless steel surface like a filamentous texture, this is just a stainless steel processing technology. The surface is matte, carefully look at the top of a trace of a trace of texture, but can not touch out than the general bright stainless steel wear, looks more on the grade of some. Drawing process will be to a certain extent, the loss of stainless steel plate thickness, generally 0.1 ~ 0.2mm. In addition, because the human body, especially the palm of the hand has a relatively strong oil and sweat secretion, stainless steel wire drawing board often touch will leave a more obvious fingerprints, need to regularly scrub. Stainless steel polishing plate refers to: stainless steel polishing plate is polished by polished stainless steel bright plate, this kind of polishing board is generally not high brightness, but also according to the blurred figure. Stainless steel mirror panel refers to: stainless steel mirror panel industry, said the dual 8K plate, also known as mirror panels, grinding fluid through the polishing equipment in the stainless steel plate surface polishing, so that the brightness of the mirror as clear as the mirror. Stainless steel mirror panel from the K number generally: 6K 8K 10K 12K these kinds. From the requirements of the coefficient points are: the general grinding 8K high Pu 8K ordinary grinding 8K fine grinding 8K ultra-fine grinding 8K these types, of course, are getting better and better. Uses: mainly used in building decoration, elevator decoration, industrial decoration, decoration and other stainless steel products. From the difference, the stainless steel wire drawing board is a long strip of lines covered with stainless steel plate. While the polishing plate is cast into a certain brightness of the stainless steel plate. And stainless steel mirror panels, can be collectively referred to as glass-like stainless steel mirror panels.

- Q: You can elaborate on this year, a variety of stainless steel products such as: tube, plate, the other, the tax rebate rate is how much

- Stainless steel sheet export tax rebate rate is generally 9 or 13 points, specifically the goods and their exports HS code.

- Q: How to degrease the wood

- Vacuum drying method The vacuum drying method is a method in which wood is piled up in a closed container and dried at a lower pressure than atmospheric pressure to remove part of the resin, and vacuum drying is suitable for wood having good air permeability. Vacuum drying method, can not achieve the desired effect. Vacuum drying is mainly characterized by drying faster than other methods, compared with other drying methods, drying time can be shortened about 25 ~ 1 2. Japan's Naito Truth [4] Drying of Douglas fir wood by high-frequency vacuum drying is considered to be effective for degreasing and mainly in the early stages of drying, since the moisture removal in the wood is in the early stages of drying, so its degreasing action is also in the early stages of drying. ] And other larch wood for cooking, vacuum and artificial drying, that cooking, vacuum degreasing effect is good, because the cooking to increase the permeability of wood.If the cooking, vacuum drying after artificial drying degreasing effect is better, because the vacuum drying Shorten the drying time.But the vacuum drying equipment is complex, the investment is high, there are vacuum drying machine manufacturers can use this method.To generally improve the degreasing effect, often using two or more degreasing method combination, such as Liquid immersion plus steam drying, pharmacy impregnation vacuum, steam vacuum pressure vacuum and other methods. The manufacturer can be based on the actual situation of the factory, choose the appropriate method for their own.

Send your message to us

PVC Foam Sheet 15 mm -20 mm Suitable For Furniture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords