PVC Foam Board Waterproof Plastic Sheets for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Product Introduction

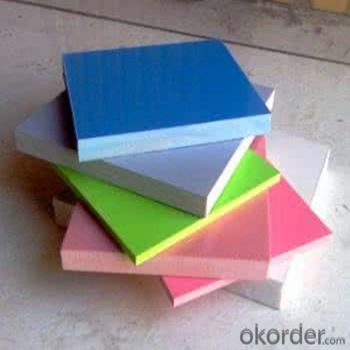

PVC foam board is made from polyvinyl chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anti-corrosive a metabolic and recyclable,moisture resistant,lightweight.

2. Details

PVC Foam Board | |

Material | PVC Foam Board |

Finish | Glossy and matte |

Application | Trade show, display,promotion,advertising etc. |

Max printing size | 30500px(width) x 61000px(length) |

MOQ | 50pcs |

Samples time | 1-3 days |

Delivery time | 7-10days and depending on Qty |

Payment term | 1.30%deposit by T/T in advance |

2.L/C, T/T | |

3.Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Environmentally green and lead-free.

4.Product Application

Construction: show window, doors, light-absorbing shade, telephone booth.

Advertisement: Lamp-house,signboard,indicator,display rack.

vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

5.FAQ

PVC foam board sheets foam board sign foam core board for shop discount

1.Q: Can you make design for us?

A: Yes, we offer custom service including sizes, printing, etc from our customers as long as they can provide available artwork to us.

2.Q: What are your company major products?

A: We have more than 10 years experience in producing cosmetic display,jewellery display,watch display,Menu holder,brochure holder,table organizer, gift and promotional items & many others acrylic products.

6.photo

- Q: i want to take out my yugioh cards but im afraid i dont want them to lose their color they are all in sheets and im inside my house but the sun is coming from the windows so will they lose color? thanks 5 star automatic

- Don't place them near windows or take them out into direct sunlight. Make sure the sheets you use to cover them are opaque because if light penetrates the sheet they will be discoloured. Put them in a cloth or cardboard cover. That always works. Good luck!

- Q: Are plastic sheets transparent to radio waves?

- No, plastic sheets are not transparent to radio waves.

- Q: Can plastic sheets be cut into custom shapes?

- Yes, plastic sheets can be easily cut into custom shapes using various cutting tools such as scissors, knives, or laser cutters.

- Q: Can plastic sheets be used for vacuum forming?

- Yes, plastic sheets can be used for vacuum forming.

- Q: Can plastic sheets be used for flooring?

- Yes, plastic sheets can be used for flooring. They are often used as a cost-effective and versatile alternative to traditional flooring materials. Plastic sheets can provide durability, water resistance, and easy maintenance, making them suitable for various settings such as garages, basements, and outdoor areas.

- Q: Are plastic sheets suitable for kitchen splashbacks?

- Yes, plastic sheets are suitable for kitchen splashbacks. They are durable, easy to clean, and resistant to water and stains, making them a practical choice for protecting kitchen walls from splashes and spills.

- Q: Can plastic sheets be used for electrical insulators in high voltage transformers?

- Yes, plastic sheets can be used as electrical insulators in high voltage transformers.

- Q: Am I on the board directly on the tapping screw, or do I plug the expansion tube first? Which is stronger?

- Therefore, it is not appropriate to use expansion bolts or expansion tubes on the boards.

- Q: Can plastic sheets be used for insulation against electricity?

- No, plastic sheets cannot be used as insulation against electricity as they are not electrically insulating materials.

- Q: Most of the iron-on transfers for dark fabrics that I have seen in arts and crafts stores are mainly for pictures. I need an iron-on transfer for letters and I'd like them to just transfer the part that's printed on, and nothing else. At shirt-making booths, they have these kinds of iron-ons that don't transfer the white background or opaque plastic-like film. I need that kind, but not in bulk. Thanks!

- at an arts and crafts store

Send your message to us

PVC Foam Board Waterproof Plastic Sheets for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords