Plastic Sheets PVC Foam Board for Wall Cladding/Decorating - Best Selling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

About us:

We are packaging foam board manufacturer, packaging foam board is becoming the substitution of wood in many fields such as AD and Decoration. We have our own factory, transportation system, overseas warehouse, industrial park.As a professional manufacturer. It made through foaming and pressing into shape with additives. The main material is PVC. So it covers not only features of woodplast, but also very light and can be printed, engraved easily.

Product Uses

1 mm- 5 mm: suitable for advertising supplies, electronic instrument, packaging

15 mm -20 mm: suitable for furniture

10 mm -20 mm: suitable for bath cabinet, cabinets

5 mm- 20 mm: exhibition board, indoor and outdoor decorative plate (different customers have different requirements)

3 mm coated :bus interior ceiling

Features:

1, light weight,good tenacity, high rigidity

2, fireproof and flame retardant

3, good insulation

4, no sopping, no deformation

5, easily to processed

6, good plasticity, being an excellent thermoform material

7, sub-light surface and elegant vision

8, anti-chemical corrosion

9, suitable to silk screen printing

10, with imported dyes, unfading and anti-aging

Product Features:

(1) Light weight, waterproof, fire retardant and self-extinguishing .

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long.

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

The Advantages:

Our products are exported to North America, South America, Europe, the middle-south Asia, the Middle East, etc., and have good market in these places. The global spread of overseas warehouse for our shipment to the nearest

FAQ

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

Q: How to get the price?

A: Please tell me the following information and I'll send you the quotation without delay:

color (white,black,grey,red,blue or other)

thickness (1mm~30mm)

size (1220x2440mm standard,customized is available)

density (0.35-0.80)

quantity(affecting the delivery time

Low Price Excellent chemical and corrosion resistance 3mm pvc foam board.

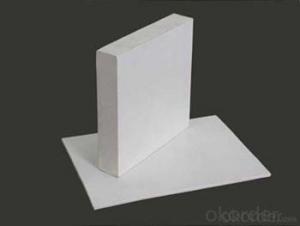

Product pictures

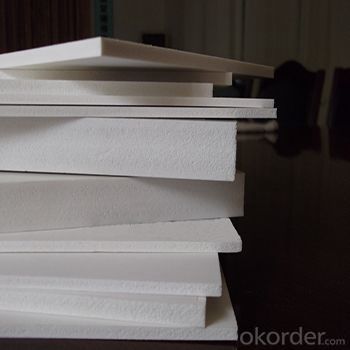

Packing picture

- Q: Are plastic sheets resistant to cracking from impact?

- Yes, plastic sheets can be resistant to cracking from impact depending on the type of plastic used and its thickness. Some plastic sheets, such as polycarbonate or acrylic, are known for their high impact resistance and are less likely to crack even when subjected to strong impacts. However, it is important to note that not all plastic sheets are equally resistant to cracking, and factors like temperature, environmental conditions, and the specific type of impact can also affect their performance.

- Q: At the end of my dentist appointment, my dentist asked to bite down hard on this black sheet of rubber or plastic and then he would pull it out.

- Sounds like he was using articulating paper. You bite on it and it leaves a colour (usually red or blue) on the teeth were they touch the opposing teeth. If your dentist has just done a filling for example they will check that they have not altered your bite by propping your mouth open or allowing no contact to be made, as both of these situations will cause problems. However if if was a rubbery mixture in a tray which was inserted over all your teeth and you were asked to bite into it, he was taking impressions. If your still unsure just ask, im bet he will be pleased to tell you hope this helps :-)

- Q: Can plastic sheets be used for skirting or cladding?

- Yes, plastic sheets can be used for skirting or cladding. Plastic sheets are often used as a cost-effective and durable option for skirting or cladding in various applications, such as in construction, interior design, or outdoor projects. They are lightweight, easy to install, and come in various colors and finishes, making them a versatile choice for enhancing the aesthetics and functionality of a space.

- Q: I want to shatter a piece of plastic to use for an art project. Is there a way to crack it into a web-like shape like this

- If your friend is going into hospital - the best thing would be that the pig stays where it lives now and you go to it to check on it. It should be ok in a garage for a week or two, but it will need to be taken out daily. Also - do you realise that your garage will forever smell like pigsh1t? You will never get rid of it - it will be on the floor, the walls and even the ceiling.

- Q: i want to make a greenhouse but i dont now what sheets they put on homemade greenhouseplease help

- Greenhouse Plastic Lowes

- Q: Can plastic sheets be used for greenhouse siding?

- Yes, plastic sheets can be used for greenhouse siding. They are a common and cost-effective material choice for greenhouse construction, as they provide insulation, allow sunlight to pass through, and are durable enough to withstand outdoor conditions.

- Q: Will plastic sheeting outside window reduce the moisture condensation inside?

- Not okorder

- Q: What are the different surface treatments available for plastic sheets?

- There are several different surface treatments available for plastic sheets, including but not limited to: 1. Coating: A thin layer of material is applied to the surface of the plastic sheet to enhance its appearance, durability, or specific properties such as UV resistance, scratch resistance, or chemical resistance. 2. Printing: Various printing techniques can be used to apply designs, patterns, or logos onto the plastic sheet, including screen printing, digital printing, or pad printing. 3. Lamination: A layer of protective film or material is bonded to the surface of the plastic sheet to provide additional protection against scratches, abrasion, or chemicals. 4. Embossing: A pattern or texture is pressed into the surface of the plastic sheet to create a three-dimensional effect or improve grip. 5. Polishing: The surface of the plastic sheet is mechanically or chemically polished to enhance clarity, smoothness, and transparency. 6. Etching: A chemical or laser etching process is used to create designs, text, or patterns by removing or altering the surface of the plastic sheet. These surface treatments can be chosen based on the desired aesthetic, functional, or protective properties required for the specific application of the plastic sheet.

- Q: Why is there a gap of 1 mm between the plastic mould, A plate and B plate? Is there a gap between the die and the die?

- Personally think that you should strengthen the basic knowledge of mold. Mold Jen is the true shape of the product cavity, if there is a gap between the mold, fitter no way out, why should match the mold or die, the mold is not the mold

- Q: Can plastic sheets be used for DIY drawer organizers?

- Yes, plastic sheets can be used for DIY drawer organizers. They are versatile and can be easily cut and customized to fit different drawer sizes and shapes. Plastic sheets are also durable and easy to clean, making them a practical choice for organizing various items in drawers.

Send your message to us

Plastic Sheets PVC Foam Board for Wall Cladding/Decorating - Best Selling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords