Cross Weave Packaging Tape with PVC Floor Marking Adhesive Natural Rubber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Discription:

Carrier:PVC film

Adhesive:Natural Rubber

Color:Black,red,blue,yellow,white,green,black & yellow, white & red, green & white

Design Printing:Offer Printing

Thickness:100-200 micron

Place of Origin:Beijing,China(Mainland)

Adhesive Side:Single Sided

Standard Sizes:50mm * 33m, 48mm * 33m, 1.25m * 33m,etc

Model Number:5113

Brand Name:Adhero

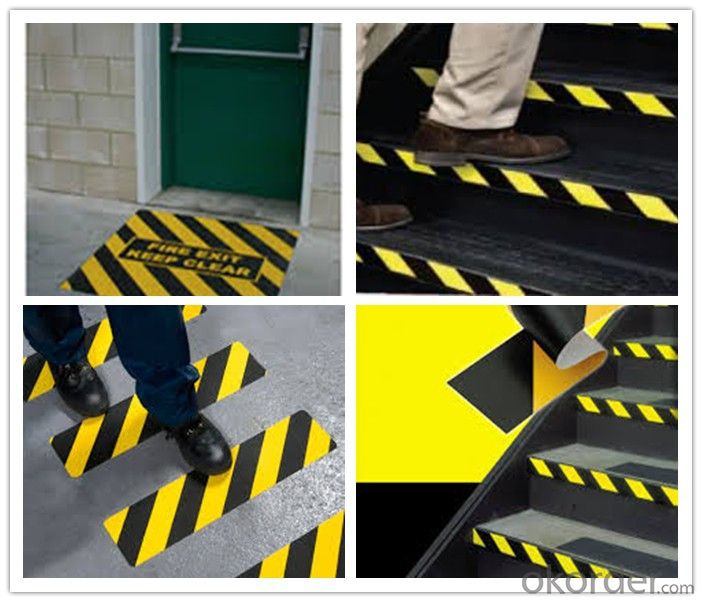

Application:widely used for floor marking of sport court,factories,offices,banks,mails,parking lots,etc.It can also be used for decorating and surface protecting.

Item No. | Thickness | Adhesion to steel | Tensile Strength | Elongation at break | Color |

5113 | 130 | 1.5 | 20 | 180 | Single |

5115 | 150 | 1.5 | 22 | 180 | Single |

5213 | 130 | 1.5 | 20 | 180 | Double |

5215 | 150 | 1.5 | 22 | 180 | Double |

5217 | 170 | 1.5 | 25 | 200 | Double |

Packaging & Delivery

Packaging Details:PVC Tape:1Roll/Shrink Wrap,18 Rolls/Carton or According to your request

Delivery Detail:PVC Tape:7-20Days or According to your request

Advantages:

Different temperature resistance with good adhesion

High tensile strength,good resistance of damage,no residue,eco-friendly

Accept custom design

SGS,ISO,BV,CTI certificates approved

Porfessional teamwork for orders

No.267 on the 2014 Fortune Global 500

Professional manufacturer with 31 years experiences of adhesive taps

Special size,color can be made according to customer's requirement.

Exhibitions

Our Services

Your inquiry related to our product & price will be replied within 24 hours.

Well-trained & experienced staff can answer all your inquiries in English or other language

Your business relationship wit us will be confidential to any third party

Good after-sale service offered please free feel to contact us for more information

Certifications

FAQ

Q 1:Do you have any MOQ of Adhero PVC Floor Marking Tape?

A:Yes, according to the size you need.

Q 2:What is the delivry time?

A:Sample time 7 days, 30 days for the mass production.

Q 3:Can we put our logo on the products?

A :Yes,welcome.

Q 4:How should I pay for you if I place order to you?

A :Usually, 30% T/T deposit in advance, 70% balance against the copy of B/L.

- Q: Is packaging tape suitable for sealing heavy boxes?

- Indeed, packaging tape proves to be fitting when it comes to securing hefty boxes. Specifically engineered to offer a robust and reliable seal, packaging tape caters to boxes of varying sizes and weights. Crafted from resilient substances like polypropylene or reinforced paper, it enhances the tape's durability and guarantees its ability to withstand the weight and pressure exerted by bulky boxes. Furthermore, packaging tape commonly possesses a potent adhesive that adheres effectively to cardboard surfaces, ensuring a tight seal capable of enduring the challenges of transportation and handling. Nevertheless, it is advisable to utilize multiple strips of tape to fortify the seal on heavy boxes, thereby enhancing their security.

- Q: Does packaging tape come with a dispenser?

- Yes, packaging tape often comes with a dispenser. The purpose of the dispenser is to make it easier and more efficient to apply the tape to packages. The dispenser typically has a handle that allows you to hold and control the tape while sealing boxes or packages. This eliminates the need to cut the tape manually and prevents tangling or wasted tape. However, it's important to note that not all packaging tapes come with a dispenser. Some tapes may need to be purchased separately, while others may be sold as a set with the dispenser included. It is always a good idea to check the product description or packaging to confirm if a dispenser is included with the packaging tape.

- Q: Can packaging tape be used for sealing plastic bags?

- Indeed, sealing plastic bags can be accomplished with the utilization of packaging tape. Designed with robust adhesive properties, packaging tape can effectively secure various items, including plastic bags. To achieve a secure seal and prevent spillage or exposure to air and moisture, the tape can be applied either along the opening or across the entire width of the bag. It is worth mentioning, though, that while packaging tape can serve the purpose, it may not be as efficient as specialized plastic bag sealing techniques like heat sealing or ziplock closures, which are specifically engineered for this particular task.

- Q: Can packaging tape be used for sealing plastic bags?

- Indeed, sealing plastic bags can be accomplished with the utilization of packaging tape. Designed with robust adhesive properties, packaging tape can effectively secure various items, including plastic bags. To achieve a secure seal and prevent spillage or exposure to air and moisture, the tape can be applied either along the opening or across the entire width of the bag. It is worth mentioning, though, that while packaging tape can serve the purpose, it may not be as efficient as specialized plastic bag sealing techniques like heat sealing or ziplock closures, which are specifically engineered for this particular task.

- Q: Selection of tapes

- So how do you choose the tape? In fact, the adhesive tape in the use of good and bad there are two criteria, one is the initial viscosity, one is to maintain the force, the two are inversely proportional. Under normal circumstances, adhesive force less than 10 adhesive tape is glue coated, teach less, usually only about 20 microns, such as stationery, tape, ordinary promotion belt used adhesive tape. The initial adhesive force of the normal sealing tape is between 15-20. The thickness of the adhesive tape is 22-28 microns. Is the standard thickness. But the tape on the market are mostly mixed with impurities, so the increase of the thickness of shielding impurities, the glue is also mixed with the toner, so transparent tape appeared egg yellow, light green, this tape is generally inferior.

- Q: Can packaging tape be used for sealing fabric?

- Packaging tape is not ideal for sealing fabric as it may not provide a secure and long-lasting bond. It is recommended to use fabric-specific adhesives or sewing techniques for sealing fabric.

- Q: Does packaging tape leave residue?

- Yes, packaging tape can leave residue on surfaces after it is removed.

- Q: Can packaging tape be used for securing pallet loads?

- Yes, packaging tape can be used for securing pallet loads. It is commonly used to reinforce and stabilize palletized goods by securing them together, preventing shifting or toppling during transportation or storage.

- Q: Is packaging tape safe to use on delicate items?

- The safety of using packaging tape on delicate items varies depending on the type of tape and how it is applied. Certain packaging tapes are specifically made for delicate items, minimizing the risk of damage through features like low tack adhesive or gentle release properties. These tapes, commonly known as "low-tack" or "gentle" tapes, are often transparent. When using packaging tape on delicate items, it is crucial to apply it carefully and securely, avoiding excessive force or pressure. It is recommended to test the tape on a small, inconspicuous area of the item first to ensure it does not cause harm or leave residue. Moreover, it is advisable to wrap delicate items with protective materials like bubble wrap or tissue paper before applying the tape. This extra layer of cushioning and protection can be beneficial. If you are uncertain about the safety of using packaging tape on a specific delicate item, it is always best to consult with the manufacturer or seek professional advice. They can provide guidance on the most suitable packaging materials and methods to ensure the safety of your delicate items during transit or storage.

- Q: Can packaging tape be used for sealing construction or building materials?

- Yes, packaging tape can be used for sealing construction or building materials, but it may not provide the same level of durability and longevity as specialized tapes designed for such purposes.

Send your message to us

Cross Weave Packaging Tape with PVC Floor Marking Adhesive Natural Rubber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords