PVC Dual Pipe Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 3 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Dual Pipe Production Line:

φ16-φ630 series PVC Pipe Production Line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agriculture and constructional plumbing, cable laying etc. This line is composed of conical twin-screw extruder, vacuum calibration tank, haul-off, cutter, stacker and etc. The extruder and haul-off adopt imported AC frequency speed controller, vacuum pump and haul-off motor all adopt superior products. The haul-off method has two-claw, three-claw, four-claw, six-claw and etc. You may choose saw blade cutting type or planetary cutting type. It is additionally attached with length counter and intensifying device. This line is of reliable performance and high production efficiency. Our company can also manufacture special pipe production lines, e.g. Spiral silencing pipe and core foaming pipe according to your requirements.

Specifications of PVC Dual Pipe Production Line

1.Heavy Extrusion Volumn

2.Modelized Temperature Control

3.Special Screw

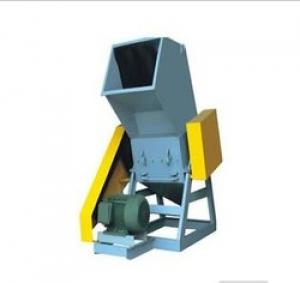

PVC pipe extrusion line has following parts:

1.Conical Double-Screw Extruder and Mould

2.Vacuum Calibrator Tank

3.Extended Cooling Trough

4.Hauling Machine

5.Cutting Machine

6.Stacker

Packaging & Delivery of PVC Dual Pipe Production Line

Packaging Details:internal inspection,boot test,Moistureproof processing,composite material box,load container.

Delivery Detail:60 days after receiving downpayment.

- Q: How are you doing now? 5Are sold where to do what products, beg again, thank you

- Waste foam recovery is market, profit is very good, but the volume is too large, inconvenient transportation. It must be compressed with a EPS foam compactor before it can be recycled. Usually compressed into blocks, in the delivery to melt, extrusion, granulation, plastic particles can be recycled material, making a lot of plastic products.

- Q: not knowing what would be feasible or what kind of machinery to buy! FiftyDo a simple understanding of, want to study, development, or more professional to point to valuable advice ha!

- This industry can, a water tank, granulator, crusher, must have high voltage, on the basic of these things.

- Q: What are the precautions in the process of recovery of pollution and regeneration equipment?

- 6., regularly check whether the operation of the normal institutions, there is no noise, such as the discovery of failure, must be promptly removed.7. installation, disassembly and adjustment of rotating mechanism, should pay attention to ensure that the rotating mechanism reducer central line and gear central line parallel, and its meshing surface is not less than 70%, meshing clearance should be suitable. Tmall America tips: haze travel, remember to do a good job of protection.8., the motor encountered overheating, to stop in time, after troubleshooting, and then continue to run, the motor bearing lubrication to be good.9. each control box, distribution box and so on often keep clean, clean the dust on the electrical equipment in time.

- Q: Dumpling stuffing machine plastic box under a triangular recycling 8 code and write SPS is what mean

- Plastic circular mark only 1-7 each symbol for each kind of plastic No 8 7 on behalf of the other 1 Pet cola bottles of mineral water bottles is 2 HDPE detergent cleaning agent bottle 3 is PVC pipe materials and other 4 LDPE plastic bag 5 is PP 6 PS bucket boxes and other plastic toys, disposable lunch boxes etc.

- Q: Where can I get recycled plastic particles? 20Xingtai also around the line, want to do waste plastics processing into particles.Do you need a lot of water to process this? Can it pollute?

- I am in Xingtai, the hand has the second-hand plastic pellet machine, the complete set of equipment 80% NEW

- Q: What equipment do you need and what price you need?

- The key is the amount of such waste There is only a mechanical separation device for steel tires.

- Q: Are there any machines for recycling waste plastic bags in domestic waste?

- Sorting devices are available, but they are imported equipment.

- Q: Is the locomotive plastic particle machine really? Is the package recycling true?

- The machine doesn't make any material, and the material you make is never acceptable

- Q: Isn't it because someone breaks the recycling machine or does it rarely use the recycle machine?I mean in Beijing

- Ha ha, the country which willing to take so much money to do this, and the one or two to you see, that it has me, you try your best

- Q: Is the plastic recycling machine the same as the sheet crusher?

- I used to screen 1.8 piglets, feces there are small particles of yellow, corn particles should not digest, good in pig, big pig no such phenomenon

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Dual Pipe Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 3 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords