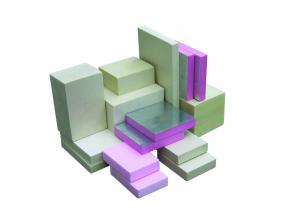

EPE Foamed Board Extrusion Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 3 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of EPE Foamed Board Extrusion Line

2.High efficiency

3.lower power consumption

4.stable

Application of EPE Foamed Board Extrusion Line:

Transportation: Such as steamship, aero plane, carriage, train compartment, roof Shed, case core layer, inner upholster, etc.

Architecture: Such as building wall board, decoration board, housing, office, public building interlayer, commercial decoration shelf, non-dust board, ceiling plate, etc.

Advertisement: Such as screen printing, computer lettering, ad board, etc.

Industry: Such as chemical industry antisepticising project, thermoforming, for refrigerator, for temperature keeping, for environment protection, etc.

Other applications: Such as mould plate, sports equipment, breeding equipment, seashore wet-proof facility, water-fast material, art material, various interlayer, etc.

Packaging & Delivery of EPE Foamed Board Extrusion Line

Packaging Details: Wooden Case

Delivery Detail:60 days

- Q: What kind of machine is needed for a small plastic bottle recycling plant to be put into operation first?.

- Can make a bottle of brick (with hydraulic baler), do the broken pieces (stripping machine, crusher), do a good PET, on the basis of the front and then need cleaning machine, dehydration machine.

- Q: and recycling of resources is the livelihood of the people, and sustainable development can not be separated from the contribution it has made. Heavy source machine 10The same is true of the historical mission, hoping to get the support and trust of the vast number of environmental protection friends, and work together to refuel it, will you? Our main products are stripping machine (stripping machine), crushing machine (crusher), PET cleaning equipment (dryer), sink, baler, knife grinder and so on.

- Advertising is reluctant to do, manufacturers are no strength of the manufacturers, the quality is difficult to guarantee

- Q: How to operate a beverage bottle recycling machine?

- Which kind of bottle do you recycle, glass or plastic?

- Q: Where can I get recycled plastic particles? 20Xingtai also around the line, want to do waste plastics processing into particles.Do you need a lot of water to process this? Can it pollute?

- Do two materials? This year's 3.15 party has exposed this matter. I hope you can learn from it. The departments concerned must be very strict with this kind of thing.

- Q: What equipment do you need and what price you need?

- Thermosetting plastics can be mechanically treated and have not been heard of standard equipment, so there is no price to follow.

- Q: Waste plastic bottle machine was acquired after breaking it

- Look what is the bottle, the general coke bottle is PET, will be more expensive, other mineral water bottles will be cheaper, probably the acquisition of the former, the price of 3500, and the latter 2500 or so

- Q: That's the kind of machine that can recycle plastic waste and process it into plastic particles. I don't know what kind of machinery it can work or need!

- Environmental protection is not pass, not in Dalian, strict grasp

- Q: What's the profit for a ton of plastic particles?

- Open the recycling of waste plastics processing plant investment funds generally need to be considered are: plant rent, utilities, wages, working capital, the recovery of raw materials, transportation costs is the key consideration of processing machinery and equipment (plastic recycling machine and plastic crusher), put these funds is a good investment is that you need to add up of course, the cost of capital, I need you according to the local situation, I know there is a plastic granulator price is above 30 thousand, the specific you called the * offer plastic machinery research. The profit of a ton of plastic pellets is about 3000-5000.

- Q: What kind of equipment should be used to recycle waste plastics such as bronzing film?

- Bronzing film, the most important thing is to rub. That's easy to fall off. Difficult is the aluminized film, need to use NAOH with high temperature..

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

EPE Foamed Board Extrusion Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 3 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords