Specifications

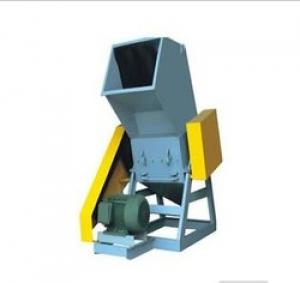

Plastic Recycling Machine

1.Suitable for plastic PP PE Film

2.Adopt Germany Technology

3.plastic recycling machinery

Technical Parameter

| Model | Motor Power | Shredding Chamber Dimension | Weight |

| SS-600 | 11kw | 550mm*600mm | 2900kg |

| SS-600 | 15kw | 550mm*600mm | 3000kg |

| SS-800 | 15kw*2sets-22kw*2sets | 600mm*800mm | 4200kg |

| SS-1000 | 22kw*2sets-45kw*2sets | 600mm*1000mm | 6800kg |

| SS-1200 | 30kw*2sets-55kw*2sets | 800mm*1200mm | 7500kg |

| SS-1400 | 30kw*2sets-75kw*2sets | 1000mm*1400mm | 10000kg |