PVC Sheet Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 3 Sets Per Quarter set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of PVC Sheet Production Line

1.Planetary extruder

2.DC motor

3.Stable performance in best price

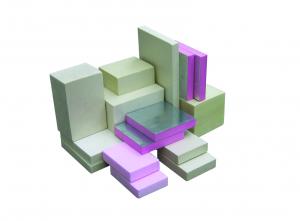

4. Produce Rigid PVC Sheet

Descrition of PVC Sheet Production Line:

1. PVC sheet production line has such characteristics as high intensity, good temperature resistance, good rot proof, etc. It can be produced with additives to different requirement such as improving intensity, improving toughness, improving rigidity, flame retardant, embossing, frosting, etc.

2. Applications: Such as packing, printing, stationery, art works, etc.

3. Main product: Gift/ad/file bag, lamp cover, food packing, etc.

4. Production scope: Thickness 0.2-2mm width Max. 2100mm

Function of PVC Sheet Production Line

1. PVC sheet production line has such characteristics as high intensity, good temperature resistance, good rot proof, etc. It can be produced with additives to different requirement such as improving intensity, improving toughness, improving rigidity, flame retardant, embossing, frosting, etc.

2. Applications: Such as packing, printing, stationery, art works, etc.

3. Main product: Gift/ad/file bag, lamp cover, food packing, etc.

4. Production scope: Thickness 0.2-2mm width Max. 2100mm

Features of PVC Sheet Production Line:

1. The screw was designed special mixed material and high plastic so that it flux plastic, color and luster equality, output heighten;

2. Clothes Model DIE was designed special double throttle, it adjust thickness of sheet exactly;

Temperature control±1°C, it can exactitude control the course of plastic and thickness and unknit of sheet;

3. Molding unit adopt horizontal and vertical, it provide more choice in the operate course of thick sheet, sheet metal by fluctuation at liberty and increase quality of sheet;

4. Adjusting thickness of sheet by screw and oil pressure pressing wheel double direction so as to achieve thickness exactly;

5. Pressing double loop cooling system, concert die temperature controller exactly control pressing wheel temperature so as to achieve unknit and thickness equally;

6. Cutter: length and quantity of sheet achieve nicely;

7 .Furling setting: it adopts senior torsion motor and four axis automatic tensions, and adjusts speed and furling tension at will for furling sheet metal unit. Dividing strip unit set width of products;

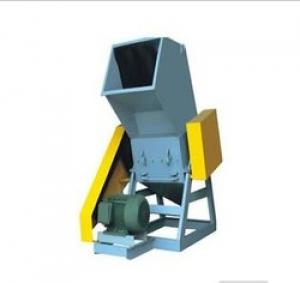

Equipment list of PVC Sheet Production Line

1. ZD3000 Screw Loader

2. ZJF-700 Spring material up-conveyer

3. SRL-Z300/600A Mixer Unit

4. PRE-150/160 two-stage roller extruder

5. 450x1200 five rolls calender and other auxiliary equipment

- Q: Waste plastics recycling machinery market prospects, consult the people to answer

- The prospects are good. The industry is concerned with protecting the environment. I believe the government will support it in the future

- Q: What equipment should be used for the recovery of organic waste gas in plastic flexible packaging plants?

- The organic waste gas in plastic factory can be treated by UV environmental treatment equipment, which can meet the national emission standard. The recycling process is complex, high recycling costs, but also cause two pollution. Usually solved by treatment and then by emission.

- Q: In what way can the filter screen be reused, 300 meshes?. Thank you

- Basically waste, 300 eyes, so small holes, so thin silk, that is, the above material heating down, the screen is also beyond recognition.

- Q: Waste plastics recycling machine where the good?

- Thick black smoke Xunde Oh, good sad Oh, look at him when on a flame, not always, my heart is on fire. Later, he bought a power machine in Chengdu Huanyu, laughing all day long. Always show off in front of us how much this item has been sold

- Q: material recycling material can do? Thank you

- We have plastic formulations and techniques that can be recommended.

- Q: What equipment do you need and what price you need?

- The key is the amount of such waste There is only a mechanical separation device for steel tires.

- Q: What are the waste recycling app?

- Four years ago, Liu Xuesong Master are reduced to the first to grab the garbage scavengers, they need to solve the problem of the shortage of raw material. Liu Xuesong worked for a well-known Japanese fashion company, and was interviewed by fashion magazines 10 years ago. By coincidence, adding itmake. At that time, the company has only two executives, another executive Yang Guangze started building traditional materials, must be in line management, manufacturing. As a result, Liu Xuesong, who is enthusiastic about going into the branding campaign, is being pushed to the forefront of recycling. "It was crazy at that time."!" Liu Xuesong told reporters, "for all recycling enterprises, the supply shortage is pain point."." Because itmake the empty bottle recycling, environmental protection will be a lot of zero discharge and dust, the processing cost is higher than others, so the empty bottle recycling price is not competitive in the market. Its design capacity is 50 thousand tons, a year of recovery rate is only more than 20 thousand tons. The machine needs to start with nitrogen at 280 degrees, once started will not stop, because of the shortage of raw materials, itmake a shutdown losses of more than 100 thousand.

- Q: How can the old plastic bottles be recycled?

- Usually, after drinking the drink, we throw the bottle and throw it into the garbage bin. We seldom care about the fate of it. If we can recycle and reuse the bottles that we have lost, it will actually produce a new oil field." Beijing renewable resources board limited company general manager Yao Yaxiong introduction, "every recycling 1 tons of waste plastic bottles, saving 6 tons of oil. Recycling plastic bottles can itmake per year 50 thousand tons, equivalent to annual savings of 300 thousand tons of oil."The last century since 90s, the international resources recycling technology and recycled plastics industry developed rapidly, many multinational companies have begun to use recycled polyester raw materials in a certain proportion in its products (i.e. waste plastic bottles): for example, Coca-Cola plans to 2011, so that all the coke bottle regeneration composition ratio reached 25%; by 100% British retailer Tesco recycled materials packaging beverage on the part of the market; recycled polyester introduced in 2008 25% in the French Evian mineral water bottle in...... Bottle grade PET chip Yingchuang company has Coca Cola Co to supply the coke bottle every 10 years there is a surplus from. The French food group Danone, Adidas and other international companies is also in talks with a surplus purchasing.

- Q: Internet plus recycling for ordinary users value?

- How can we integrate the 100 thousand line recovery army? Before the O2O concept became so hot, Chang Tao had been thinking about it. In 2014, Chang Tao introduced his classmate to find a vice president of SF Beijing company and visited the SF system. "A lot of people don't think SF is O2O, but did you find out?" SF and didi taxi like, the only difference is that people do not use in mobile terminals, but just call express." "The efficiency of SF is high because it has a powerful IT system," he said. Through the IT system integration channel is the simplest, this is easy to do, IT is the old Tao Tao business. Chang Tao called his logic "reverse logistics system": "SF sends the factory's products to thousands of households. I am sending all the things from the household to the factory, which is similar to each other."! The waste recycling industry for decades as one day, and in addition to change, little change. Beijing has 200 thousand people engaged in this industry, including Henan, Gushi County accounted for 70%. There are 100 thousand lines of waste collection, others do sorting and so on, they send out 8 million tons of waste every year for Beijing. The surface of the loose organization actually closely related to him, there is a problem to find a way of running predecessors, similar to the old guild society. The advantage of this kind of organization is efficiency and low cost. Special changtao wants to keep the industry, he won't hire more employees and a recovery "jobs", but the individual garbage collection are integrated in a platform, everyone is still responsible for the original line area. This not only does not require the company to pay salaries, it can help the garbage collector with itmake platform to increase recycling business more for themselves. With changtao own words, cooperation and the wilderness army, he did "just add a system to solve the problem of information asymmetry".

- Q: The state promotes environmental protection every day. Improve white pollution. But it is allowed to import foreign plastic garbage It's a great pollution to our country. Why did the State Environmental Protection Agency ignore it? Of course, I know that plastic processing profits objectively. We can expect that an ordinary small town per day at least processing 1000 tons of garbage, water pollution air land serious, the whole country will be the number of garbage is imported, the daily pollution is more serious? Really do not understand ~! ~! ~! Why doesn't it matter? Are there enough domestic waste to deal with? Go and be a foreign garbage collector... I Pooh ~ ~! ~!! I Pooh ~ ~ ~ ~!

- First, the system is not perfect, two is driven by interest, and three are corrupt people.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Sheet Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 3 Sets Per Quarter set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords