Rubber To Fuel Oil Refining Pyrolysis Plant with Carbon Pellet Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 15 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | sea worhty packing |

| Delivery Detail: | 15 days |

Specifications

output oil and carbon

1.Safety with full safety device,auto alarming

2.Low investement bring you high profit

Detailed Product Description:

1.Save energy

2.Long service time

3.Short delivery

Oil yield of different raw material

PE | 50%-75% |

PP | 50%-75% |

PS | 50%-75% |

ABS | 40% |

Leftovers of paper | Wet 15-20%, dry 60% |

House garbage | 35-50% |

Plastic cable | 80% |

Plastic bag | 50% |

Submarine cable | 75% |

Rubber cable | 35% |

Sole | 30% |

Big tires | 45-50% |

Small tires | 35-40% |

PVC | Not suitable |

PET | Not suitable |

- Q: Beijing metro station plastic bottle recycling machine location?

- On the Metro Line 10 at JinSong Railway Station and Shaoyaoju station, two machines are placed at each station.

- Q: If I make small pieces of the machine in Japan, do I have a place to recycle them?Who knows the specific whereabouts of the plastic bottles such as Coke bottles in Japan? If I make small pieces of the machines in Japan, can I get them back? How much is a ton? Can it work in Japan?

- All I know is all recycled by the recycle bin, but it's really not clear how it works after it's recovered.Is LZ in Japan? Do you plan to smash it and sell it in Japan or in China?

- Q: Can I recycle the toner cartridge? Improper plastic waste!

- Toner used up, you can continue to use toner, if you can not use toner cartridges can be recycled, sell worthless, about 5 to 10 yuan

- Q: How are you doing now? 5Are sold where to do what products, beg again, thank you

- Guangdong city of Zhongshan Province, a returnees entrepreneurship - Zhongshan hivac Environmental Technology Co. Ltd., the first bubble compaction machine is used to compress the bubble volume, the brick shape, small size, large weight, this can greatly improve the efficiency of recycling waste foam, to solve the previous problem of foam recycling transportation costs.This machine start is mainly for foreign markets, both at home and abroad. The exhibition, domestic counterparts are competing to imitate, the domestic market is gradually opened, I think, China's recycling industry profit bubble is just in the stage of development, there are some special institutions to collect pressure after shrinking the foam block China should also have. Like upstairs said, many small items are made of these bubbles, great potential for development, who wants to change treasure, you have to quickly understand the market ah.

- Q: not knowing what would be feasible or what kind of machinery to buy! FiftyDo a simple understanding of, want to study, development, or more professional to point to valuable advice ha!

- What's your particle?! It's easier to find a market! Well, I have. It's a little far away. I'm from HebeiThe

- Q: What are the recycling of waste plastics in refining equipment?

- Only the worst plastic will be refined, and a little better plastic will not be taken by anyone. It's too wasteful.

- Q: what equipment and how much money do you need?I Liaoning Panjin people, the existing covers an area of about 300 square meters, and now want to open a small plastic recycling materials processing plant, I do not know what equipment, how much money, what the future!!!!

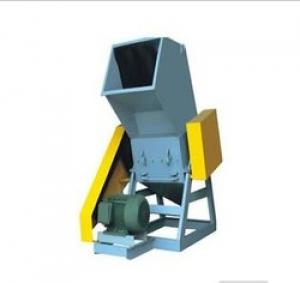

- To tell you the truth, this line of profit has been very low now. The equipment is very simple, the crushing machine, feeding machine, granulating machine, granulator, plant. Money to at least remortgage. Raw materials into the freight yard, sales, find their own way. The answer is complete. Hope to be useful to you ~ ha ha!

- Q: What are the precautions in the process of recovery of pollution and regeneration equipment?

- Note the use of sand recycling machine machine Braun think this is mainly due to the daily use of details, if daily use pay more attention not to damage the machine, it can prolong the service life of the machine, so the Braun listed items in some sand recycling machine for daily use should pay attention to.1. after the sand recovery machine is installed, the institutions should check and adjust regularly to ensure the flexibility and reliability. In the friction surface, there should not be any dirt, dirt must use gasoline or thinner wash.2., should pay attention to check each department screw has broken wire and loose stock phenomenon. If it exceeds the relevant regulations, it must be renewed immediately.

- Q: It's a package of cookies, crisps, and the like

- It belongs to plastic garbage and can be recycled.Food packaging bags should be made of food grade plastic film, usually composite bags of more than two layers.Utilization of waste plasticsRecycled materialThe recycling and reuse of waste plastics has been widely adopted by modern chemical enterprises. Waste plastics after artificial screening classification, but also through crushing, granulation, modification process, into a variety of transparent opaque plastic particles, again according to the product classification, finally it can be recycled again by the.FuelIn the beginning, plastic recycling was largely done by burying or incinerating, which resulted in great waste of resources. Therefore, foreign waste plastics are used for blast furnace injection instead of coal, oil and coke. It is used for cement rotary kiln instead of coal, firing cement, and making solid waste fuel (RDF) for power generation, the effect is ideal.

- Q: Internet plus recycling for ordinary users value?

- How can we integrate the 100 thousand line recovery army? Before the O2O concept became so hot, Chang Tao had been thinking about it. In 2014, Chang Tao introduced his classmate to find a vice president of SF Beijing company and visited the SF system. "A lot of people don't think SF is O2O, but did you find out?" SF and didi taxi like, the only difference is that people do not use in mobile terminals, but just call express." "The efficiency of SF is high because it has a powerful IT system," he said. Through the IT system integration channel is the simplest, this is easy to do, IT is the old Tao Tao business. Chang Tao called his logic "reverse logistics system": "SF sends the factory's products to thousands of households. I am sending all the things from the household to the factory, which is similar to each other."! The waste recycling industry for decades as one day, and in addition to change, little change. Beijing has 200 thousand people engaged in this industry, including Henan, Gushi County accounted for 70%. There are 100 thousand lines of waste collection, others do sorting and so on, they send out 8 million tons of waste every year for Beijing. The surface of the loose organization actually closely related to him, there is a problem to find a way of running predecessors, similar to the old guild society. The advantage of this kind of organization is efficiency and low cost. Special changtao wants to keep the industry, he won't hire more employees and a recovery "jobs", but the individual garbage collection are integrated in a platform, everyone is still responsible for the original line area. This not only does not require the company to pay salaries, it can help the garbage collector with itmake platform to increase recycling business more for themselves. With changtao own words, cooperation and the wilderness army, he did "just add a system to solve the problem of information asymmetry".

1. Manufacturer Overview

| Location | Jiangsu,China (Mainland) |

| Year Established | 2002 |

| Annual Output Value | |

| Main Markets | North America1.33 South America 3.32 Eastern Europe6.64 Southeast Asia 18.59 Africa 6.64 Eastern Asia 3.72 Domestic Market 59.76 |

| Company Certifications | CE;ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Rubber To Fuel Oil Refining Pyrolysis Plant with Carbon Pellet Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 15 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches