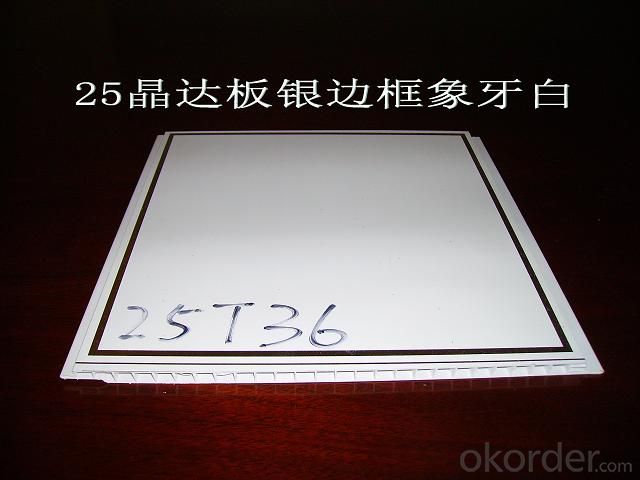

PVC Ceiling Panels Price in India - Modern Design Plastic Printing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

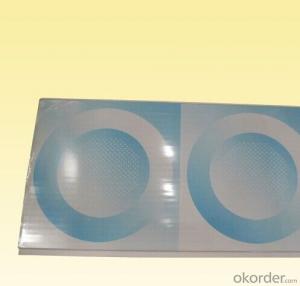

PVC ceilings are the ideal way to deliver tempered air from preheated hallways to farrowing or nursery rooms. The hollow profile acts as an air plenum delivering the air through precisely sized and positioned holes. The air enters the room uniformly without creating drafts.

Product Applications:

PVC ceiling panels solves the problem of dirty, unhygienic ceilings that are difficult, and expensive to clean by providing a bright, durable and hygienic surface, which is easily maintained. This extremely practical ceiling system is suitable for any area requiring a fixed, non-porous, non-fibrous and non-absorbent ceiling.

Product Advantages:

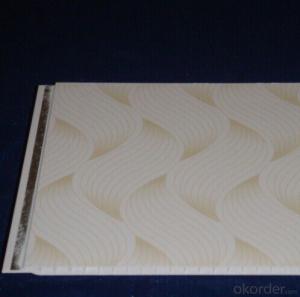

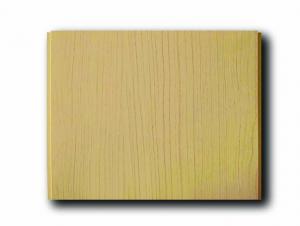

PVC Ceilings has various advantage over other materials namely they are waterproof, Termite Proof, Fire Retardant, Economical, Maintenance free, being non-porous and non-absorbent, can incorporate flush fitting lighting, access hatches, air vents and sprinklers easy to install & available in various colours shades & no hassles of Painting & Polishing.

Main Product Features:

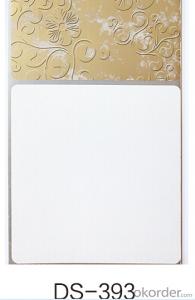

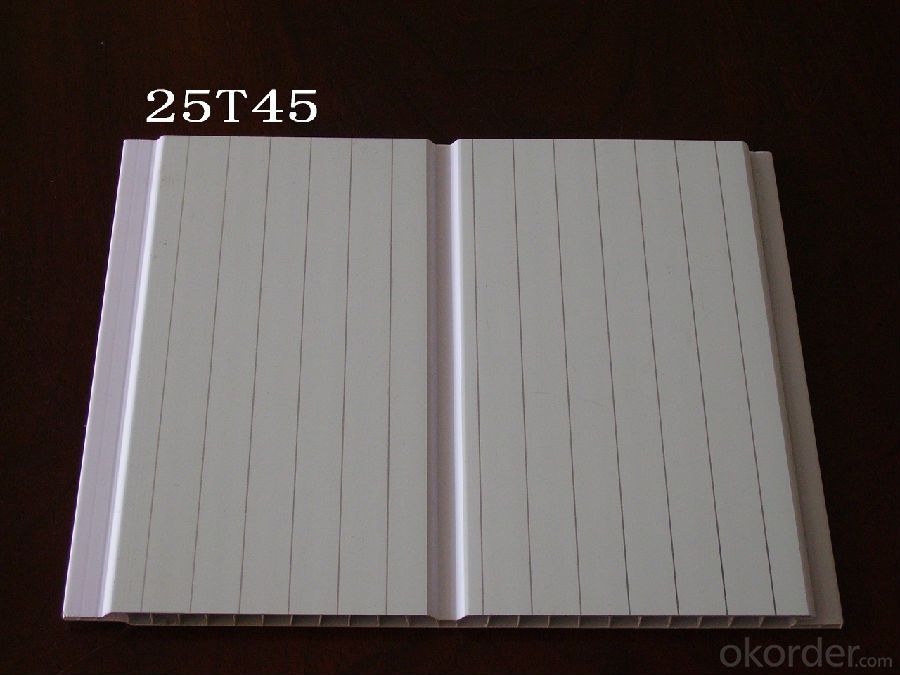

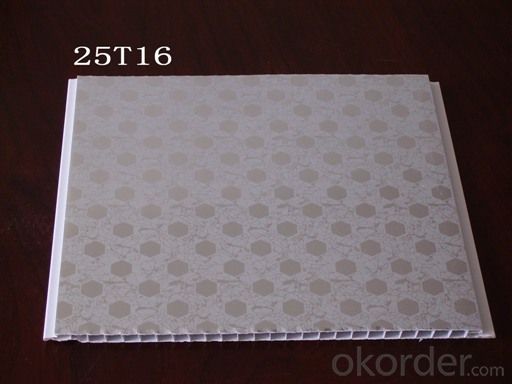

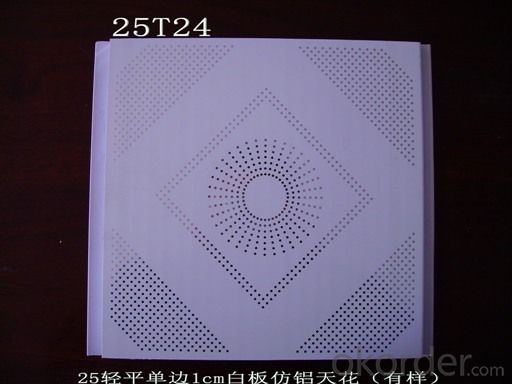

1. Artistic Ceilings, Honeycomb Ceilings, Integrated Ceilings, Perforated Ceilings

2.Easy getting and cleaning

3.Waterproof and fireproof

4.Environmental and friendly

5.Certificate: TUV Rheinland

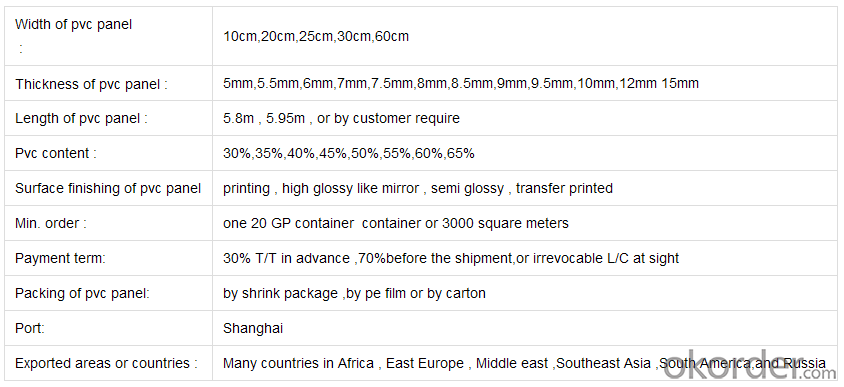

Product Specifications:

FAQ:

(1) Where are the ceiling panel applied?

The panels are designed for covering internal walls or ceilings in any room in the home or commercial rooms.

Especially for the wet environment, such as the kitchen and the bathroom.

(2) How can I install the panels?

Our panels are designed to be installed by the DIY’S. We also provide you with the installation profiles.

You just need very little experience and no special tools.

(3) What temperature range I can use plastic panels in?

New design PVC Panel can withstand temperatures up to 140°F (60°C)

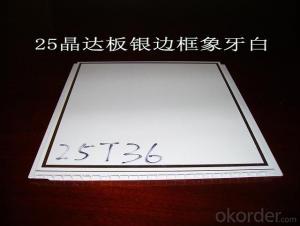

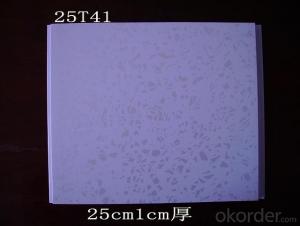

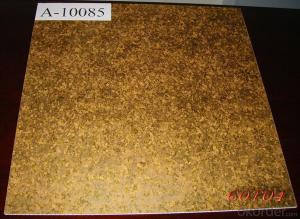

Images:

- Q: How to pack the decoration pipe

- Home pipes are generally in the bathroom and kitchen, The kitchen of the pipe is made of woodworking board, Bathroom pipes need to consider the waterproof, you can use PVC board, aluminum plate can also be used, but it is thin, not strong, pay attention to the clear port position to stay out to prevent one day use.

- Q: Cement floor self-adhesive PVC floor is good or glue glue that kind of good

- PVC flooring is divided into two kinds: coil and sheet, coil series has thousands, the most common is the coil (commercial floor) Regardless of home improvement or commercial or stadium and dance dedicated, are generally recommended the use of coiled floor, floor leather referred to as civilian leather hand about Sri Lanka break, leather life year old flowers, price: 5-20 yuan a square meter, the real Flooring leather referred to as plastic floor or PVC floor life of at least 6 years, up to 50 years, the price: 38-180 yuan a square meter, consumption are clear whether the floor leather or leather, different materials, different prices, different thickness of different prices, different Texture of different prices

- Q: Looking at my exposed ceiling in the basement, I see two copper pipes coming out of the water heater, one marked in blue (assuming cold) and one in red (hot). These each split between supplying the upstairs and downstairs.After the split, there are galvanized steel pipes. I get great water pressure downstairs in the utility sink and clothes washer.Upstairs, pressure to the dishwasher, kitchen sink, and bathroom shower is terrible. It takes about 10 full seconds to fill a pint of water in the kitchen. You can imagine how long it takes to get a sink full of soapy water.Showers are annoying too with lack of pressure. I'm thinking I'll bring a plumber in to replace the piping to the upstairs. With a very amateur eye, I see about 10-15 total feet that'd need replacing.Is replacing it the answer? Or might there be something that could be locally repaired?Any estimates on cost for this?

- if the pipes are in good working order than i wouldnt bother replacing them. the problem is the water pressure is not good enought to push the water up at an increased speed. you will need to instal a water pump to increase water pressure, these arent very expensive look between ?100 to ?200 for a decent one, then say 4 hours of plumbers labour costs at roughlt ?80-?100. the pump will need an electrical feed so the parts for that and electricians labour costs. be careful though as higher water pressure may bring out leeks that u didnt know were there as older pipes sometimes cnt stand the new high pressure.

- Q: Ordinary PVC board can be posted wallpaper? Or paint is mainly to improve its appearance

- Paint for the PVC, but this has been decorated with a board of non-professional paint will not flat, do not look blanket! Willing to spend money, you can find manpower painting chanting

- Q: PVC plastic hard board maximum temperature how much

- Pvc in the temperature of 110 to 140 degrees between the temperature and then a little higher will melt into liquid, the temperature and then into a low powder.

- Q: Pearl board pvc board distinction

- PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q: Snow board is not pvc board, how the difference ah?

- the same

- Q: What is the difference between plastic flooring and floor leather?

- Flooring is the traditional simple ground decoration materials, cheap: 10 yuan / m2. Buy back can be laid on the ground. Products certainly not so durable. Plastic floor or PVC plastic flooring from product quality, hardness, beautiful, durable, Clean, all levels are much stronger than the floor leather, the price from 45 yuan. Installation fee of about 25. Good products are 150 yuan or 500 yuan / m2 have.

- Q: Decoration company people said that the aluminum plate to do the effect will be better. But some people say that the length of the aluminum plate is easy to deformation (especially Yuba near the board). What are the quality of the decision? Generally do not buy the thickness of the number of deformation? In addition, my house upstairs from the ceiling of the water pipe is relatively large, the lowest point of the water pipe from the ground also 2.3m. Hanging shed will not appear after the height of the bathroom is too short. Is there a good way to fix it?

- Aluminum buckle plate better. Aluminum plate: a metal aluminum buckle products. The combination of high quality metal aluminum as the base material and the perfect surface treatment process, in terms of quality, personality, vision, surrounded, etc., have unparalleled advantages, at present, aluminum slab board to improve the industry standards and products Its own charm, occupy the kitchen and toilet ceiling of the main material status, but the product has always been high in the price, becoming one of the hot spots in the market competition, the current market kitchen and bathroom ceiling to aluminum-based board. PVC is polyvinyl chloride, English referred to as PVC (Polyvinyl chloride), vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in the peroxide, azo compounds and other initiator; or in the light, heat by free Based polymerization mechanism polymerization polymerization of the polymer. Vinyl chloride homopolymer and vinyl chloride copolymer collectively referred to as vinyl chloride resin. The material is a non-crystalline material. PVC materials in the actual use of often added stabilizers, lubricants, auxiliary processing agents, colorants, impact agents and other additives. With non-flammability, high strength, weather resistance and excellent geometric stability. PVC has a strong resistance to oxidants, reducing agents and strong acids. However, it can be strongly oxidized acid such as concentrated sulfuric acid, concentrated nitric acid corrosion and does not apply with aromatic hydrocarbons, chlorinated hydrocarbons in contact with the occasion. A few years ago in the market is very popular, but now due to environmental issues, led directly to the market trend. PVC is easy to deform, and aging quickly.

Send your message to us

PVC Ceiling Panels Price in India - Modern Design Plastic Printing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords