PVC Ceiling Panel Price Philippines - Cheap 60x60 PVC Ceiling for Decoration Different Types

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (PVC Ceiling ) Description

Specifications:Gypsum Ceiling / PVC Laminated Gypsum Ceiling Tiles / Gypsum Ceiling Board

Color of Gypsum Ceiling: White, Colorful

Sizes of Gypsum Ceiling: 595X595mm, 600X600mm, 603X603mm, 605X605mm, 595X1195mm, 600X1200mm, 605X1212mm, 605X1210mm

Tolerance of Gypsum Ceiling: length <±2mm, width < ±2mm, thickness <±0.5mm< strong="">

*The above prices are for white and if colorful, US$0.15/M2 has to be added.

*If sealed with edge-tape, USD0.04/M2 has to be added.

2,Main Features of the (PVC Ceiling )

*Validity of Prices: 30 calendar days

*Minimum Ordering Quantity: 2X20ft containers

*Payment Terms: T/T or L/C at sight

*Shipping Date: 15 days after receiving prepayment or L/C

*OEM available at US$0.03/M2.

*Daily Output: 120,000 M2 of PVC Laminated Gypsum Ceiling and 200,000 per day.

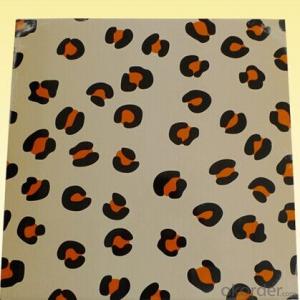

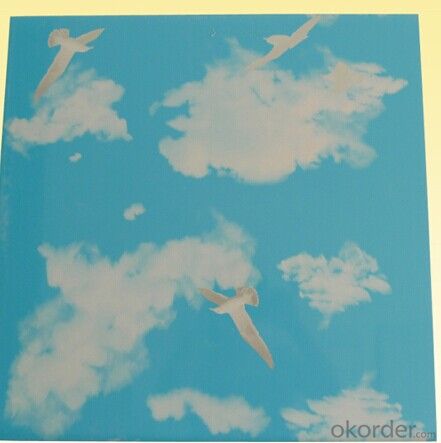

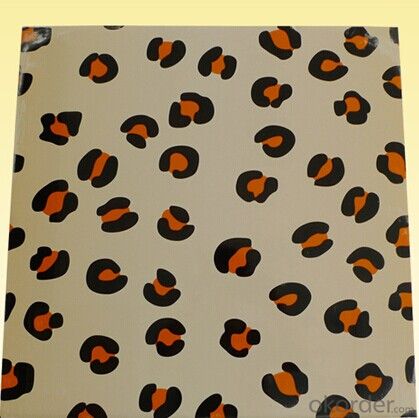

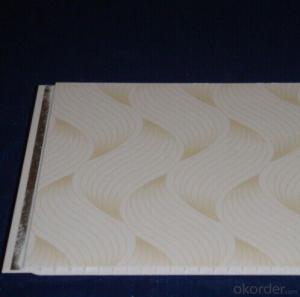

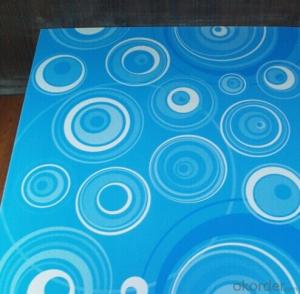

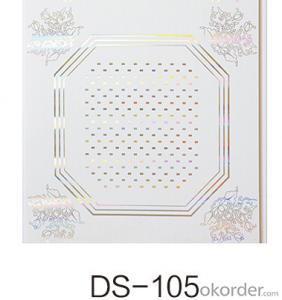

3,(PVC Ceiling ) Images

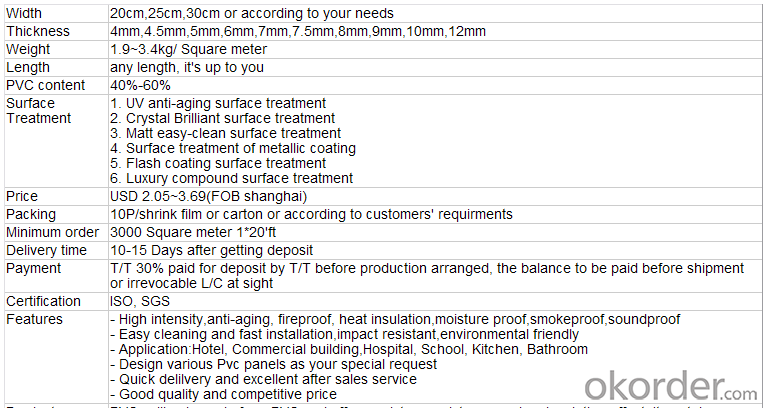

4,(PVC Ceiling ) Specification

5,FAQ of (PVC Ceiling )

1)Normal oil printing.

2)Hot stamping.

3)Thermal transferring print

4)Laminated print

7.Surface finishing effect: White / Glossy / High glossy / Gleam etc.

8.Applications:Home kitchen,bathroom,indoor,hotels,hospitals,commercial buildings,meeting room,schools etc

- Q: In addition to paint board, the door there are plastic panels, fire board, PVC board, solid wood and other styles. How can I choose?

- It has a waterproof fire performance. Price is moderate, so it has become a popular choice of cabinets, but it is not very upscale. Blister board substrate for the MDF, the surface made by vacuum or a seamless PVC film Compression molding process. Blister-type door color, woody realistic, monochrome color pure and brilliant, no cracking is not deformed, resistant to scratch, heat, dirt, anti-fade, is the most mature cabinet material, and routine maintenance is simple. But the price is high .. so the choice of a, according to the product performance, style, the last is to consider their own spending power of the ..

- Q: PVC wood plate for the decoration of the store facade can be used?

- Is it the door of the store? Or is your store's sample? If it is the shop seems wrong. The sun will be discoloration, muster, shedding possible

- Q: My home PVC board is always issued a flap sound, how is it? (My family is not the top floor)

- The ceiling of the plate that may be caused by the deformation of the keel need to open to see the corporal is not a keel deformation go

- Q: Pvc plastic acid corrosion

- Resistance, people's metering pumps are used above.

- Q: What are the disadvantages of PVC glue?

- PVC floor defects: ???????? 1, the construction of high demand ???????? 2, afraid of cigarette butts ???????? 3, non-natural materials ???????? Homogeneous heart PVC flooring defects: ???????? 1, the construction of high demand ???????? 2, poor stain resistance, must always wax maintenance ???????? 3, poor wear resistance ???????? 4, poor dimensional stability ???????? 5, afraid of cigarette butts ???????? 6, a single color, not enough diversity ???????? 7, poor impact resistance

- Q: Ordinary pvc board can heat moisture it?

- PVC board for the family to choose the economy The most common and cheapest ceiling material. It's PVC as raw material, light weight, waterproof, moisture, moth. As a result of the production process to add a flame retardant material, the use of safety. PVC board a variety of types of colors and patterns, imitation mostly plains, but also patterns, imitation marble pattern. Honeycomb network structure, its cross-section, both sides of the mouth and the shape of the mouth. Such materials should be noted that the choice of surface should be free of cracks or scratches. I should be straight, every mouth is smooth, there is no ups and downs and the local phenomenon of the height difference. The sheet can be bent, elastic, and the hand is percussed with a crisp sound of the surface without sinking a certain amount of pressure. Its shortcomings are poor resistance to high temperature performance, warm environment for a long time easy to deformation.

- Q: At present home decoration used in white, beige panels have those? Type with PVC board?

- White maple, white oak, white pine, rose wood, ruminant wood,

- Q: What are the specific national standards for pvc? The

- Want to figure out, PP forum, a lot of PVC film information, there are a lot of PVC film and printing bag to do friends, many of which are in the first line operator, responsible for the technology. There are also PVC particles

- Q: Pvc floor construction costs how much money a square meter

- 6 yuan, with the whole price to see the construction site, laying the request may be

- Q: Pvc transparent plate and the difference between acrylic

- VC transparent board and acrylic (PMMA) board difference: The main difference is: 1. Transparency and environmental protection, acrylic (PMMA) environmental protection is better than PVC, some manufacturers of PVC may be added in its formula inside the plasticizer (plasticizer), plasticizer choice is not good words , Will be harmful to the human body; 2. Transparency: Acrylic (PMMA) transparency is better. 3. The other is the price, PVC raw materials cheap, acrylic (PMMA) raw materials expensive.

Send your message to us

PVC Ceiling Panel Price Philippines - Cheap 60x60 PVC Ceiling for Decoration Different Types

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords