Pushing Type Precast Concrete Purline Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pushing Type Precast Concrete Purline Production Line

1. Structure of Pushing Type Precast Concrete Purline Production Line:

Pushing Type Precast Concrete Purline Production Line is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Pushing Type Precast Concrete Purline Production Line:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Pushing Type Precast Concrete Purline Production Line Images:

4. Prefabricated Concrete Purline Compression Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

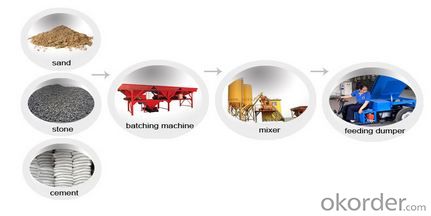

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: What is the best way to invent something? Like and industrial piece of machinery.?

- think of something that would make a job easier, safer, or more cost efficiant

- Q: Which machinery makes this type of packaging /bags?

- I don't like links.

- Q: would these include non motorized equipment used for processing?

- Baler------ This is pulled by the tractor and used to make bales out of crops like hay. It makes a round bale that is 4'x4' tall. Each bale will feed about 25 cows a day. Combine------ This is used to harvest all kinds of crops. It does more than one thing--like pick and clean the crop. It has a sieve in it to get rid of the crop junk. They even have special ones if the farmer has lots of hills. Chisel Plow----- Plows dig up the soil to get it ready for planting. It will turn over the dirt as it digs. Cotton Picker----This machine picks cotton and puts it into the back. The cab has air conditioning and a cassette player/ radio/ and weather radio. It has a special seat for back support. Mower---- This is pulled by a tractor and mows down grass and low growing things. Row Planter---The containers at the top hold the seeds to be planted. This is pulled across the field that the farmer wants to plant. Row Planter---The containers at the top hold the seeds to be planted. This is pulled across the field that the farmer wants to plant. Seed Drill--- This is pulled by a tractor. It is used to plant grains and vegetable seeds. This can make different kinds of ditches that the seeds go in depending on what kind of soil there is. Sprayer--- This is used if the farmer needs to spray their crops for anything [like bugs]. It has a great cab, or place where the driver sits. The equipment company builds these to make farmers more comfortable while they work. Tractor--- This is one of the most important pieces of equipment that a farmer has. He uses it to pull equipment and crop wagons. The equipment company makes the cabs of these very comfortable, too. The farmer picks the tractor size based on what he wants to pull with it. ()

- Q: please explain at 1 or 2...or 3. no current experiment please like knockout mice.

- 1) the Avery,Mcleod and Mccarty experiment. 2)the Hershey and Chase experiment. _ Hershey and Chase conducted their experiments on the T2 phage, a virus whose structure had recently been shown by electron microscopy.In their first set of experiments, Hershey and Chase labeled the DNA of phages with radioactive Phosphorus-32 (the element phosphorus is present in DNA but not present in any of the 20 amino acids from which proteins are made). They allowed the phages to infect E. coli.were able to observe the transfer of P32 labeled phage DNA into the cytoplasm of the bacterium.n their second set of experiments, they labeled the phages with radioactive Sulfur-35 (Sulfur is present in the amino acids cysteine and methionine, but not in DNA). Following infection of E. coli they then sheared the viral protein shells off of infected cells using a high-speed blender and separated the cells and viral coats by using a centrifuge. After separation, the radioactive S35 tracer was observed in the protein shells, but not in the infected bacteria, supporting the hypothesis that the genetic material which infects the bacteria was DNA and not protein hope it helps.:)

- Q: Have you ever driven heavy machinery like a fork lift?

- I never have personally, but I work with people who drive them everyday. I work in manufacturing. There's a little tug machine I drive sometimes but its simple and more like driving a car than a forklift.

- Q: can you give me the reviewer for electric machinery by fizgerald (5th ed) pls...?

- Magic Eight Ball says... “Yes - definitely.”

- Q: i want to sell a candle an unused candle extruder i bought couple of years ago, which internet sites can help me do that?

- Goto okorder

- Q: what is difference between machinery and equipment?

- What Is Machinery And Equipment

- Q: What are the effects of heat treatment on the mechanical properties of metallic materials

- Tempering: Reduce and eliminate the internal stress of steel after quenching. Stable organization and size.

- Q: required - biscuit production machinery and bottle water production machinery from turkey and china and malaysia

- google it

Send your message to us

Pushing Type Precast Concrete Purline Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches