Precast Pressed Concrete Purline Pillar Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Precast Pressed Concrete Purline Pillar Machine

1. Structure of Precast Pressed Concrete Purline Pillar Machine:

Prefabricated Concrete Purline Compression Molding Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Precast Pressed Concrete Purline Pillar Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Precast Pressed Concrete Purline Pillar Machine Images:

4. Precast Pressed Concrete Purline Pillar Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

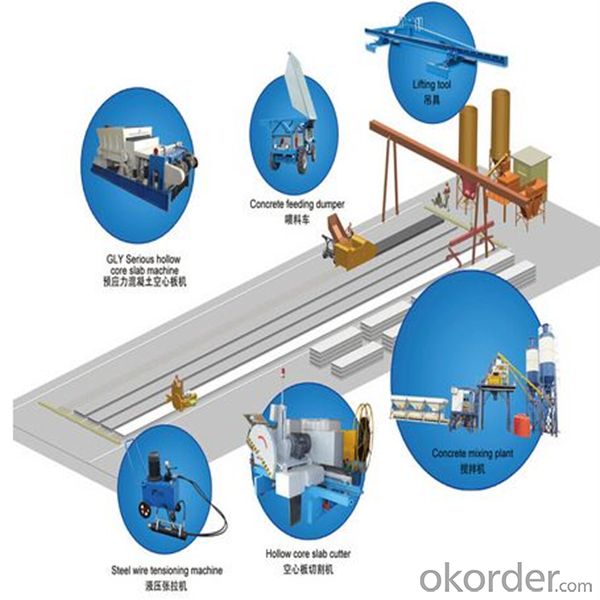

Production Line Layout

Production Process

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

8. Why choose us:

• 30 years manufacturing experience.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: ....i should just glue my mouth shut...

- Nope, ruined your robot

- Q: Efficency , Cost-effective

- PHARMACO okorder /

- Q: If the machinery that accomplishes X-chromosome dosage compensation in humans was defective (e.g., 1 protein was mutant), what do you expect the consequences would be? Choose one. a) no consequences b) XX embryos would not be viable c) XY embryos would not be viable d) both XX and XY embryos would not be viable

- B

- Q: A. United StatesB. Latin AmericaC. JapanD. Western EuropeI'd say Latin America since it's most likely the poorest of that bunch, but I'm not sure. Any ideas?

- That's okorder /

- Q: what does machinery safety engineer do?

- Basically, they inspect every machinery and make sure that it is perfectly functional and that all safety standards are met. Safety engineers are also involved in the planning and consultation in the event that a machine is required to be moved or relocated. Safety engineers plays a major role in a machinery relocation firm such as the www.hanlonandwright .uk/.

- Q: I'm in 7th grade so please dont make this too difficult to understand.Thanks. :]

- try this site

- Q: Do engineering technicians get to invent and patent ideas within large companies, or is this typically reserved for the mechanical engineers?

- Mostly, engineer's are problem solver's. In the case of mechanical engineers. you are partly correct. They are given a problem, like they need a machine that can build a part or perform some action, but has to fit within certin peramiters. So the engineer has to figure out how to make it work. But this is only a small part of what an engineer does.

- Q: electric digram for desel generator wih 105 kva

- Call or write to the manufacturer.

- Q: Needing to know if you have elevator equipment in the back part of an office downstairs in the basement, is there anything put out by this equipment that can cause sickness?

- It's unlikely. There's more than one type of elevator, but I don't believe any of them use poisonous gas or asbestos.

- Q: Like only 90 or 120 degrees, but it's precisely controlled.Thanks!

- The steering on your car.

Send your message to us

Precast Pressed Concrete Purline Pillar Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords