Prestressed Concrete Purline Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prestressed Concrete Purline Forming Machine

1. Structure of Prestressed Concrete Purline Forming Machine:

Prestressed Concrete Purline Forming Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Prestressed Concrete Purline Forming Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Prestressed Concrete Purline Forming Machine Images:

4. Prestressed Concrete Beam machine for House Specification:

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

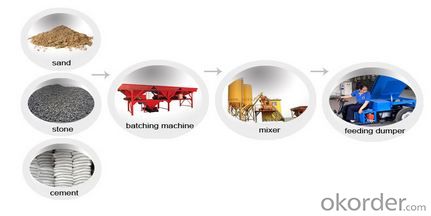

Production Process

Rebar tensioning

Raw materials preparing

Molding

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: ....i should just glue my mouth shut...

- good one . . . i think :)

- Q: Payback: Quebec, Inc., is purchasing machinery at a cost of $3,768,966. The company expects, as a result, cash flows of $979,225, $1,158,886, and $1,881,497 over the next three years. What is the payback period?

- Plugging okorder /

- Q: if not how much would you pay for one if i did it (NOT)

- If you did it, the chances of reliable accuracy would be small, no matter how good you are.

- Q: How to make full use of slaughtering machinery scalding pool?thanks?

- Blowers scalding hot pool outside the pool so water inrush current composition of poultry fulfill staggered through electromechanical effects of propeller pumping hot water pool outside it, for it is rinsed, so both ends of the local hot pools million drug is not easy too small, too small will be staggered friction temperature for poultry

- Q: what are the machinery in which threads are used for power transmission?

- Ball screws and ACME screws are often used as the means to provide thrust in a linear actuator. Linear actuators are present in many, many applications.

- Q: I hate working out in public gyms and exorcise rooms if other people are there for some reason. And I hate running in public (I've ran at night before, but now I don't have any time with so much schoolwork). I was wondering what some good exorcises i can do at home every day that don't take long but will make a difference. I was hoping to work my stomach muscles more so i can get in shape for swimsuit season. Thanks! (:

- brisk okorder

- Q: why are larger fields needed for machinery such as combine harvesters,tractors and ploughs?

- To have economy.

- Q: Like only 90 or 120 degrees, but it's precisely controlled.Thanks!

- Agitator on a washing machine. Garage door opener. Vibrations on a vibrator. So on and so forth.

- Q: I'm not talking about luck, faith or chance but about instinctive wisdom. Your place in life and how easy or hard it was for you to connect the dots starting from scratch.

- The cosmic machinery seemed to have began my life with a great karmic debt which had to be paid off. Until I stopped resisting it was a constant struggle which I blamed God for giving me a rotten hand in life. I used to think, if I knew then what I know now I would do things much differently. But then I think, had I foreseen how things would turn out and how I could possibly be changing the synchronistic events that has made me who I am, then maybe I wouldn't be who I am right now. Today I love the person I am, flaws and all. Sure, I still want to develop and become a better person to others and myself, but I can accept that I'm still growing and needed to endure and come through the changes I did to get where I'm at today.

Send your message to us

Prestressed Concrete Purline Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords