PU Sandwich Panel Production Machine with ISO quality system

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

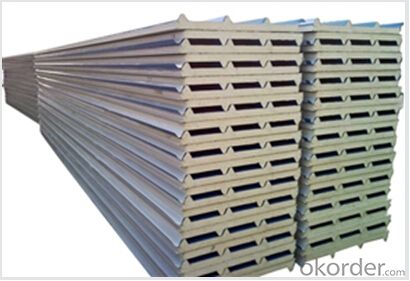

PU Sandwich Panel Production Machine

Brief introduction

Our PU sandwich panel machine is one line that integrates advanced mechanical, chemical, electrical, hydraulic, and pneumatic technologies. Due to its high efficiency and simple operation, this forming machine is widely used in the construction of steel structure enclosures, cold storages, and mobile buildings. In order to satisfy various customer requirements, we design and manufacture PU sandwich panel lines in different specs, models and configurations.

Main Components

PU sandwich panel machine mainly consists of hydraulic uncoiler, film covering system, roll forming machine, polyurethane foaming system, double belt system, automatic cutting device, electric control system, hydraulic system, and pneumatic system. Stacking system and packing system for option.

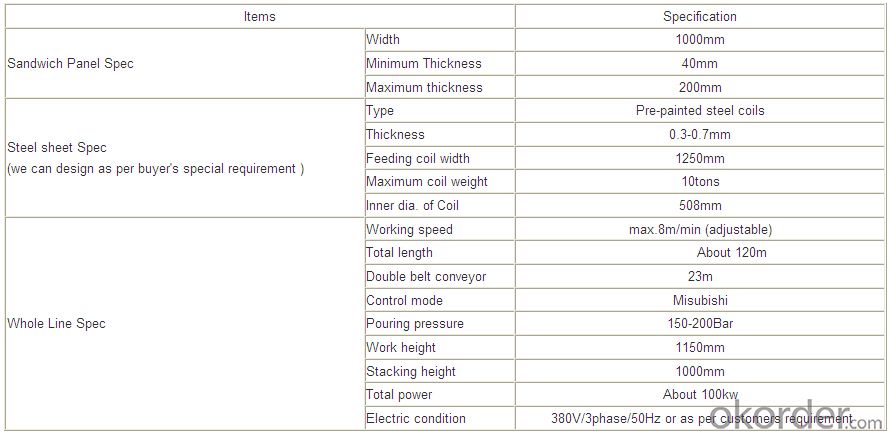

Technical specification

Product application of PU Sandwich Panel Production line

Due to its high efficiency and simple operation, this forming machine is widely used in the construction of steel structure enclosures, cold storages, and mobile buildings.

In order to satisfy various customer requirements, we design and manufacture PU sandwich panel producton lines in different specs, models and configurations.

Competitive Advantage:

<!--[if !supportLists]-->1. <!--[endif]-->Designed by 15 years experienced R&D members with lifetime seivices.

<!--[if !supportLists]-->2. <!--[endif]-->We are "All-in-house source" factory to ensure quality and delivery of your machines.

<!--[if !supportLists]-->3. <!--[endif]-->Machine’s lifetime>15 years

<!--[if !supportLists]-->4. <!--[endif]-->Quick delivery: in only 5-8 weeks for urgent order .

<!--[if !supportLists]-->5. <!--[endif]-->Introduced Mitsubishi PLC and touch screen for machine’s control system.

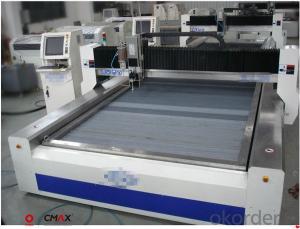

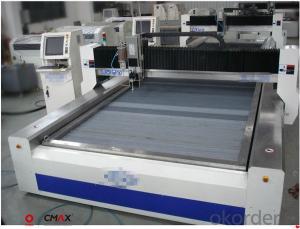

<!--[if !supportLists]-->6. <!--[endif]-->Have our own tool center: 12 sets of CNC machines.

<!--[if !supportLists]-->7. <!--[endif]-->High Pricision perofrmance: Shafts are tooled by grinding machine for two times. Rollers are tooled by CNC machines.

<!--[if !supportLists]-->8. <!--[endif]-->Technician can be sent to your factory to install machines and train your workers.

- Q: Say that China's machine is not good, then they are sold to whom?

- In the basic processing, domestic machine tools have a higher price.

- Q: What is the instrument lathe, how to use it?

- Of the production and processing, metal processing industry is the most efficient high-efficiency equipment.

- Q: How many kinds of machine tools

- According to the use of metal cutting category CNC machine tools, including CNC lathes, CNC drilling machine, CNC milling machine, CNC grinding machine, CNC boring machine and processing center

- Q: What equipment, machine tools, lathes, or other equipment? Probably are a length of not more than 30cm a number of hollow

- linoleum, tubing and oil separator, etc. should be complete and well installed. According to the lubrication instructions

- Q: What can a CNC lathe do?

- Write a program to hand grinding tool.

- Q: The difference between CNC machine tools and ordinary machine tools

- The other is all mechanical components, there is no automatic control system.

- Q: The basic structure and function of machine tools

- 3, feed mechanism, used to change the feed; spindle box to install the machine tool spindle;

- Q: The processing range of the lathe

- Usually in the metal cutting machine occupies the largest proportion, accounting for about 30% of the total number of machine tools.

- Q: Is not the United States or Germany developed countries, ordinary lathe has been eliminated, or has been replaced by other new lathes

- did not put this time out of Germany to China now seems like the country only 5

- Q: What is the characteristic of Taiwan's Cheong Hong machine compared to other machine tools? Compared to Shenyang Machine Tool, Gao Feng machine, Friends of Ka?

- Peak is to take the low end of the line, certainly not better than Che-hung.

Send your message to us

PU Sandwich Panel Production Machine with ISO quality system

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords