Sandwich Panel Production Machine with CE certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PU Sandwich Panel Production Machine with CE Certificate

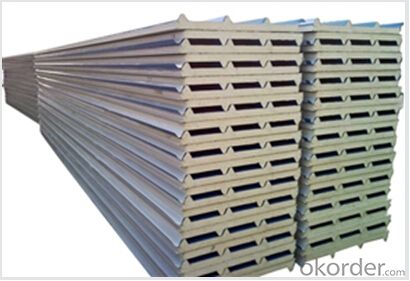

Description of PU Sandwich Panel Production Machine

Our PU sandwich panel Production line is one line that integrates advanced mechanical, chemical, electrical, hydraulic, and pneumatic technologies.

Technical Data of PU Sandwich Panel Production Machine

Sandwich Panel Spec | ||

Min. cutting length | 3 meters | |

Max. stacking length | 15m | |

Panel width | 1000mm (can be designed as per client’s requirment) | |

Panel thickness | Mini thickness | 40mm (corrugated sandwich panel) |

Max. thickness | 150mm(exclude corrugated sandwich panel) | |

Steel Sheet Spec | ||

Thickness | 0.4-0.7mm color steel sheet | |

Width | 1250mm (can be designed as per client’s requirment) | |

Max. coil weight | 10 tons | |

Inner Dia. of coil | 508mm | |

Whole Line Spec | ||

Working speed | About 3-7m/min (adjustable) | |

Total length | about 105m | |

Working height | 1200mm (height of panel coming out) | |

Pressure for foaming | 150-200 bar | |

Double belt conveyor | 23m | |

Control mode | Mitsubishi PLC and converter | |

Total power | About 100Kw (as per final designing) | |

Power required | 380V/3phase/50Hz or as per customer''s requirement. | |

Air pressure | 0.7Mpa (for buyer to prepare) | |

Product application of PU Sandwich Panel Production Machine

Due to its high efficiency and simple operation, this forming machine is widely used in the construction of steel structure enclosures, cold storages, and mobile buildings.

In order to satisfy various customer requirements, we design and manufacture PU sandwich panel producton lines in different specs, models and configurations.

Competitive Advantage:

1. Designed by 15 years experienced R&D members with lifetime seivices.

2. We are "All-in-house source" factory to ensure quality and delivery of your machines.

3. Machine’s lifetime>15 year

4. Quick delivery: in only 5-8 weeks for urgent order .

5. Introduced Mitsubishi PLC and touch screen for machine’s control system.

6. Have our own tool center: 12 sets of CNC machines.

7. High Pricision perofrmance: Shafts are tooled by grinding machine for two times. Rollers are tooled by CNC machines.

8. Technician can be sent to your factory to install machines and train your workers.

- Q: Say that China's machine is not good, then they are sold to whom?

- But into the field of precision machining, domestic machine tool precision level and degree of automation than imported machine tools or no small gap.

- Q: What is the instrument lathe, how to use it?

- Widely used in electrical appliances, fasteners, cars, motorcycle accessories, instrumentation, hardware, cultural and educational supplies, video equipment, mechanical and electrical products, plumbing fittings, valves, bearing rings, shafts and other small parts,

- Q: What equipment, machine tools, lathes, or other equipment? Probably are a length of not more than 30cm a number of hollow

- Check that each turret should be in a non-working position;

- Q: In the machine practice, only allow a student to operate alone, other students should do

- the other students should carefully see how the operation of the operator,

- Q: What is the meaning of R in the data lathe?

- The meaning of other letters in CNC lathes:

- Q: How to categorize cnc lathes

- With the traditional car, milling, drilling, grinding, gear processing corresponding to the NC machine tools CNC lathes, CNC milling machines, CNC drilling machines, CNC grinding machines, CNC gear machine tools and so on.

- Q: What is the CNC machine?

- CNC machine tools are digital control machine (Computer numerical control machine tools) for short, is a program control system with automatic machine tools.

- Q: The difference between CNC machine tools and ordinary machine tools

- While the CNC machine tools are not complicated by the variable speed mechanism because its motor is computer-controlled stepless.

- Q: Is not the United States or Germany developed countries, ordinary lathe has been eliminated, or has been replaced by other new lathes

- Can not say that should be said to be sold to the poor development of the country 90 years

- Q: Shenyang machine i5 machine only how?

- Are imported things, as if the servo motor is Japan, the turret stability should have no problem, this knife in the other models are used.

Send your message to us

Sandwich Panel Production Machine with CE certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches