PS Foamed Picture Frame Extrusion machines equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

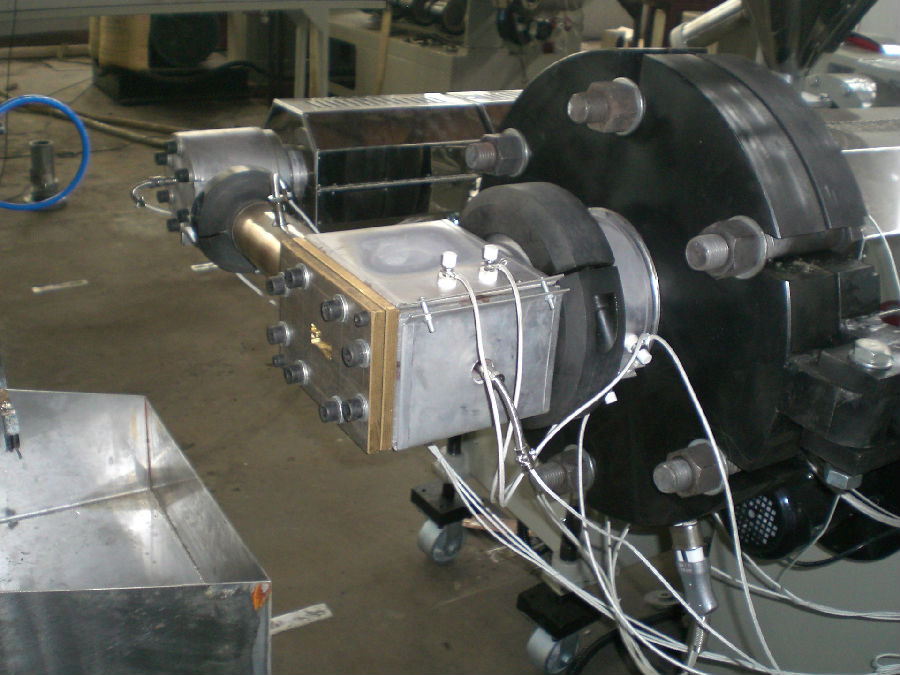

PS Foamed Picture Frame Extrusion machines equipment

1- Foamed Polystyrene Profile Extrusion Equipment for PS decoration can make Polystyrene Foamed Skirting Profile, Polystyrene Foamed Decoration Profile, Polystyrene Foamed Picture Frame, Mirro Frame, Photo Frames, which can replace the tradition wooden frame profiles, the costs are much lower and the quality is much better than wooden profiles.

2- The main raw materials are recycled PS, mixing with little some other additives in different formulas, such as HIPS, EPS, Foaming, DOP TiO2 (about 4-5 kinds), this can get different quality profiles for various application, adopting low foam technology which can save more materials cost in production for Foamed Polystyrene Profile Extrusion Equipment for PS decoration.

(1) High-speed Mixer: THE FIRST STEP before Foamed Polystyrene Profile Extrusion Equipment for PS decoration.

(2) Hot-stamping & Embossing Machine: the most advanced technology to decide profile quality.

(3) PS Profile Crusher: Recycle waste head materials and damaged profiles to crush less than 15mm

Main technical parameters:

Model | Production line speed | Production line power (KW) | Appearance size (mm) |

PS65 | 2-6m/min | 50 | 27000×1600×2100 |

PS75 | 2-7m/min | 60 | 28000×1600×2100 |

PS90 | 1-5m/min | 90 | 33000×1700×2100 |

PS100 | 1-6m/min | 100 | 34000×1700×2100 |

PS120 | 1-3m/min | 130 | 35000×1700×2100 |

- Q: Basic parameters of extruder screw

- 2. The ratio of the length to diameter of the screw, the length of the screw L/Ds and the ratio of L to the diameter of the screw Ds is called the ratio of length to diameter. When the other conditions are constant (such as the diameter of the screw), increasing the ratio of length to diameter means increasing the length of the screw. The L/Ds value is large and the temperature distribution is reasonable, which is beneficial to the mixing and plasticizing of plastics. At the same time, the heating time of the plastic in the barrel is longer, and the plasticization of the plastic will be sufficient and more uniform. So as to improve the quality of machine plastics. If the plastic quality requirement is constant, the rotation speed of the screw can be increased after the ratio of length to diameter increases, thereby increasing the extrusion amount of the plastic. However, too large length diameter ratio, power consumption will increase the screw, and the screw and barrel of the processing and assembly of chicken more difficult; the possibility of screw bending will increase, will cause the abrasion of the screw and the inner wall of the cylinder, reduce the service life. In addition, the heat sensitive plastic, large diameter and long retention time than thermal decomposition, the plasticizing and impact plastic extrusion quality. Therefore, in the full use of the advantages of increasing the ratio of length to diameter, the selection should be based on the physical properties of the processed plastics and the quality requirements of the products.

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- When making documents, they are not in accordance with the actual situation.

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- Adjust the assembly and check the exhaust block

- Q: PVC extrusion machine extrusion stone floor no pressure, what reason?

- PvC stone floor extruder pressure is adjusted by the screw and die head

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- They can see it moving.God doesn't need itSometimes you hear, fifth hand material,Cool sounds in the swirling smokeCoagulation together, I have left their land,Yesterday was a similar experience, ha ha

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- It depends on experience, and the lines made by squeezing it are solid. When you make the line, you can see the expansion and skewness of the material!

- Q: How to adjust the 65 screw gap in the extruder?

- This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

- Q: What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- 1, extrusion methodAccording to plasticizing methods: dry extrusion and wet extrusionPress the way: continuous extrusion and intermittent extrusion2, characteristicsContinuous production, high efficiency, simple operation, wide range of applications [Edit] paragraph extrusion molding equipment 1, the hostExtrusion system: composed of screw and barrel, it is the key part of extruder. Its function is to melt plastics, quantitative, constant pressure, constant temperature extrusion of meltDrive system: drive the screw to increase the required torque and torqueHeating and cooling system: guarantee the temperature of plastic and extrusion system in molding process2 auxiliariesIt is composed of head, setting device, cooling device, traction device, coiling device and cutting3 、 control systemIt consists of electric apparatus, instrument and actuating mechanismPurpose: to control the main and auxiliary motor, in order to meet the demands of speed and power; control main engine temperature and pressure and flow, to ensure product quality; to achieve automatic control of the extrusion unit, ensure the coordinated operation of main and auxiliary equipment. [edit this paragraph] extruder extruder overview of plastic extruder is the host, it consists of extrusion system, transmission system and the heating and cooling system.

Send your message to us

PS Foamed Picture Frame Extrusion machines equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords