CMAX Output PS Foamed Picture Frame Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wooden case |

| Delivery Detail: | 30working days after receiving the prepayment |

PVC PS Plastic Foamed Profile Production line

This line can produce high quality low foam profiles for users.

This production line is mainly composed of extruder and SJBZ low foam profile auxiliary machine combined with advancement, reliability and practicability. This line can produce high quality low foam profiles for users.

CMAX Series PS Foam Profile Extrusion Line, consists of single screw extruder and the special co-extruder, with the cooling water tank, hot stamping machine system, haul-off unit, and stacker.

This line with imported ABB AC inverter control, imported RKC temperature meter etc. and features of good plasticization, high output capacity, and stable performance etc.

The hot stamping machine system combined foreign technology, by the hot stamping embossing method, transfer the

coating layer from the film to the PS foamed profile. The machine with good appearance, stable performance, accurate & easy operation.

By adjust the embossing wheel the machine can work on various of different profiles.

Working together with the main extruder and other extrusion down steam equipments, this line is popular as the latest developed producing line.

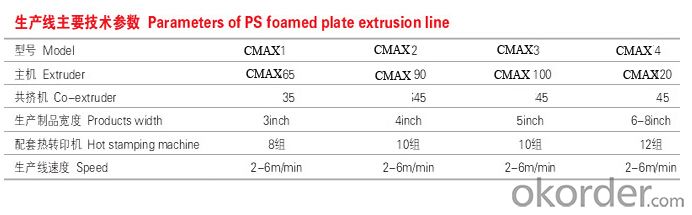

Main technical parameters:

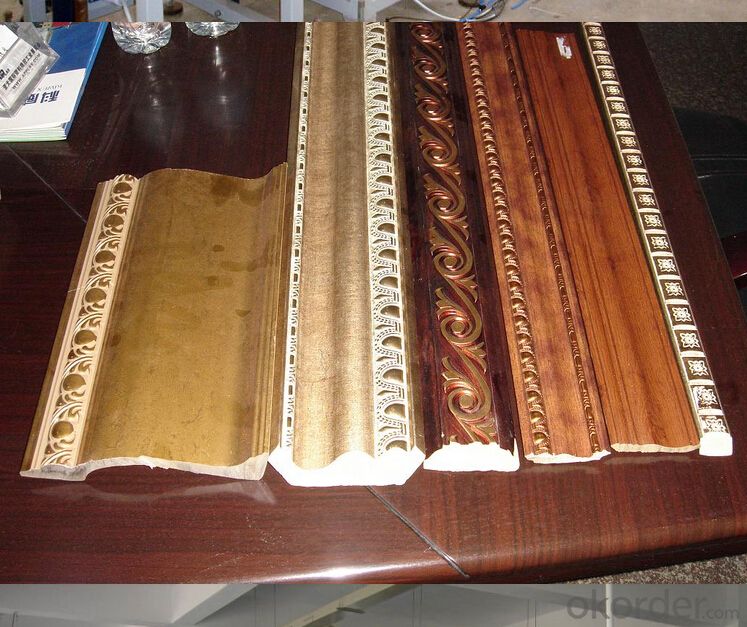

Product show:

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Pay attention to the ground anchor.It is better to fasten the joint of the equipment itself.

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc. 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- In fact, if you are familiar with that extruder, there will be no problem!

- Q: How to adjust the 65 screw gap in the extruder?

- This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- There is a kind of broken engineering material. I wonder if you can find it

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

- Q: What are the components of an extruder?

- An extruder in which an air vent is disposed at the center of an exhaust extruder to allow removal of air and volatiles from the processed plastic. The main machine of plastic extruder is plastic extruderIt consists of an extrusion system, a drive system and a heating and cooling system. 1. extrusion system extrusion system includes screw, cylinder extrusion die head, extrusion die head, molding parts of the extruder. Also known as extrusion die, extrusion die. The utility model has the function that the plastic melt from the extruder barrel is well distributed in the die runner so as to be extruded and formed from the die at a uniform speed. The forming action of an extrusion die is in the process of complete extrusion (see plastics processing). A plastic extruder consists of an extrusion system, a drive system and a heating and cooling system. The classification system of extrusion system includes 1. extrusion screw, barrel, hopper, head, and mould, plastic extrusion system by plasticizing evenly into the melt, the establishment of Liu Hesheng basic information name in this process and Liu Hesheng taught: - professional engineeringControl science and EngineeringJob: in gender: Male College: College of mechanical and power engineering representative paper: melt rotating twin screw extruder in conveying flow solving teaching: research direction: mainly engaged in polymer material processingLinear low density polyethylene (LLDPE) linear low density polyethylene (LLDPE) linear low density polyethylene is structurally different from the generallow density polyethylene

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- What are the operating specifications for the extruder?One is the equipment instructionTwo is the boot operation specificationsThree is safety instructions and so onThe equipment manufacturer will provide the above

Send your message to us

CMAX Output PS Foamed Picture Frame Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches