Propex Geotextile Coir Fiber Logs for Soil and Water Erosion Control

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | roll with cardboard core,bale with plastic film |

| Delivery Detail: | within 20 days |

Specifications

1.reducing civil engeineering overall costs

2. cost efficiency

3.high strength,low elongation

4.corrosion resistance pervious

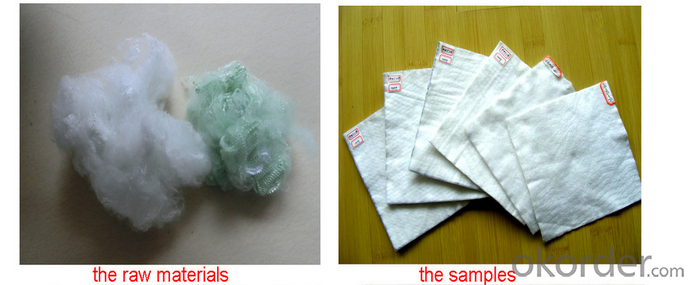

Brief introduction:

Polyyester multifilament yarns are woven into a stable network.A woven geotextile retain its relative structure during handling,placement and long time service. As needed, geotextile material shall be added stabilizers to make the filaments resistant to ultraviolet light,oxidation and heat. Reducing civil engineering overall costs increases construction project life filtration separation reinforcement,erosion control high strength,low elongation corrosion resistance perviousness easy transportation dimensional stabilization speed construction cost efficiency

Polyester Woven Geotextile

Material: Polyyester

Color: white

Width:1.06-3.7M

Weight: 270gsm-1700gsm

Tensile strength: 50KN/M-800KN/M

permeability:0.01-0.8S-1

Pore size: 0.06-0.7mm

Elongation: Polypropylene<15%< span="">

interweave method:plain, twill etc.

Benefits:filtration,separation,reinforcement,erosion control

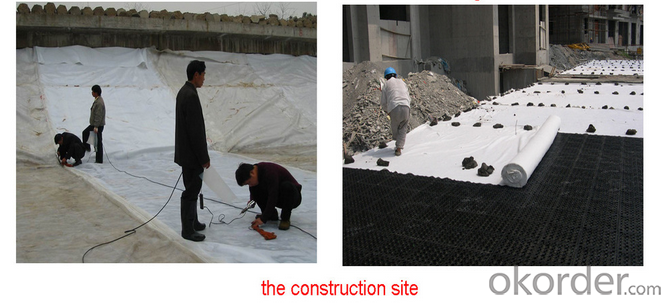

Civil and environmental applications: including highways, port facilities, reservoir, transport construction,

waste and chemical management, subgrade engineering, coastal protection works, peninsula shoal

engineering, subsurface drainage ,pile jacketing etc.

MAIN PRODUCTS

(1) High Strength Woven Geotextile

(2)Pile Jacketing

(3)Geotextile Curtain (Silt Curtain)

(4)Concrete Revetment Mattress

(5)Geotextile tube,Geotextile bag

Physical properties | Test method | Unit | Typical Value | |||||||

Material | Polyester/PET | |||||||||

Color | White | |||||||||

Unit Weight | 270 | 360 | 540 | 430 | 810 | 1200 | 1200 | 1700 | ||

Tensile Strength at break MD | ASTM D 4595 | KN/M | 100 | 150 | 150 | 200 | 400 | 300 | 500 | 800 |

Tensile Strength at break CD | ASTM D 4595 | KN/M | 50 | 50 | 150 | 50 | 50 | 300 | 100 | 50 |

Elongation at break MD | ASTM D 4595 | % | <=15< span=""> | |||||||

Elongation at break CD | ASTM D 4595 | % | <=15< span=""> | |||||||

Permitivity | ASTM D 4491 | S-1 | 0.01-0.8 | |||||||

Pore opening size O90 | ASTM D 4751 | mm | 0.06-0.7 | |||||||

FAQ:

♦ Payment terms: by T/T or L/C |

♦ MOQ:2000 SQM |

♦ If you are interested in our products ,pls advice me the technical index,product weight etc,the more information the better..... |

- Q: Can geotextiles be used in bridge construction?

- Yes, geotextiles can be used in bridge construction. Geotextiles are commonly used in bridge projects to reinforce the soil, provide drainage, and prevent soil erosion. They can also help in stabilizing the ground, improving the overall performance, and extending the lifespan of the bridge structure.

- Q: Geotextile in the asphalt layer under what role

- Geotextile play the role of reinforcement, protection.

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: Geotextile what are the specifications of the ah?

- Geotextile is first divided into short wire geotextile and filament geotextile. Their specifications generally according to the weight to count, small equipment, geotextiles are mostly between 80g-380g, and now some mature domestic enterprises generally can do between 100g-1500g short wire and filament geotextile. How many grams of this can be customized between. It should be noted that the same specifications of the short wire geotextile price than the filament geotextile to 30% cheaper, but the technical strength index than the long geotextile cloth nearly 50%.

- Q: Geotextile price in the end is how much?

- Geotextile raw materials are also different prices, geotextile prices with the market changes, geotextile prices from one yuan to twenty yuan variable. After-sales service and thoughtful, customer satisfaction as the goal. Hongxiang geotechnical

- Q: Filament, preferably concrete construction

- Tianhai new material filament geotextile case analysis of water conservancy projects: seawall, river embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project.

- Q: Roof garden pool at the bottom with pebbles, pebbles above with geotextile, geotextile above the soil

- Should be installed drainage board it! Geotechnical material manufacturers to answer!

- Q: Geotextile GB and Dahua What is the difference between looking at almost ah

- GB is the current national industry standards, Dahua is from the raw materials to distinguish, Huazhi geotextile material manufacturers

- Q: How do geotextiles help with reinforcement of geosynthetic tubes?

- Geotextiles help with reinforcement of geosynthetic tubes by providing additional strength and stability. They act as a barrier between the soil and the tube, preventing soil erosion and maintaining the shape and integrity of the tube. The geotextile fabric also helps distribute the load evenly across the tube, preventing localized stress and potential failure. Additionally, geotextiles can improve filtration and drainage, allowing water to pass through while retaining the soil particles, thus enhancing the overall performance and longevity of the geosynthetic tube.

- Q: Can geotextiles be used for reinforcement of underground tunnels?

- Yes, geotextiles can indeed be used for the reinforcement of underground tunnels. Geotextiles are flexible, permeable materials that can provide support, stability, and prevent soil erosion in various civil engineering applications, including tunnel construction. They can be placed to reinforce the surrounding soil and prevent movement or collapse, enhancing the structural integrity of the tunnel. Additionally, geotextiles can also act as a drainage layer, allowing water to flow through while minimizing soil saturation, which is crucial for long-term tunnel stability.

Send your message to us

Propex Geotextile Coir Fiber Logs for Soil and Water Erosion Control

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords