PVC Ceiling in India - Proof PVC Ceilings Cmax Brand 2024 New Style Artistic Fire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

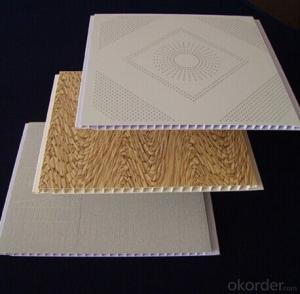

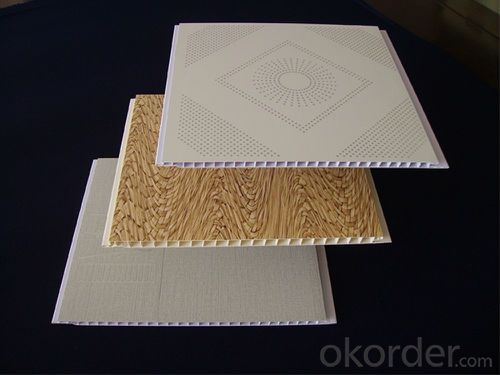

Thickness (mm): 5mm/5.50/6mm

Width (cm): 20cm

Length (m): 0.595-5.95 (according to customer requests)

Weight(kg/SQM): 1.60kgs/1.70kgs/1.80kgs

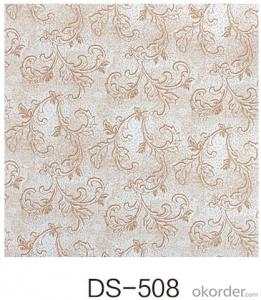

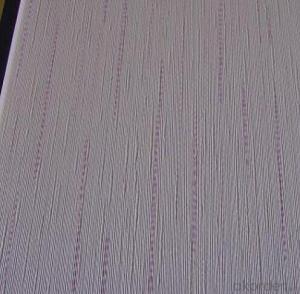

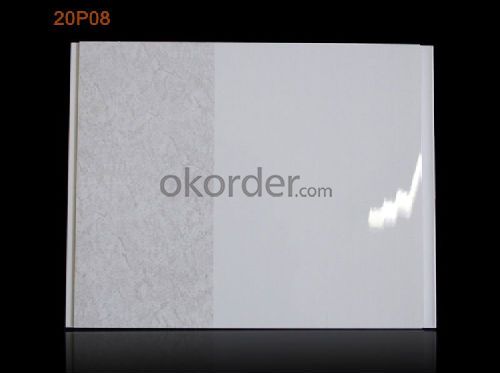

Surface Treatment

Common and High glossy Printing, transfer printing, Laminating with permanent glue, any design as

customer request

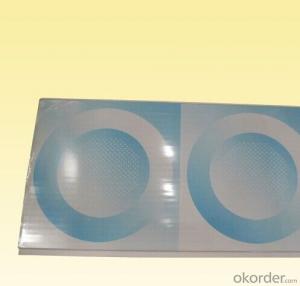

Package

PE Film Packing, PVC Film Packing, Hard Paper Box Packing

Product Advantages:

1. Surface treatment: printing, transfer printing and lamination with permanent glue

2. High intensity, high breaking strength, strong colour fastness not easy to deformation, erosion resistant,

mothproof, sound insulation, waterproof, flame retardant, antibiosis, environmental and non-toxic material ,

3. Easily installation, smooth surface, flat, without gap when concatenated

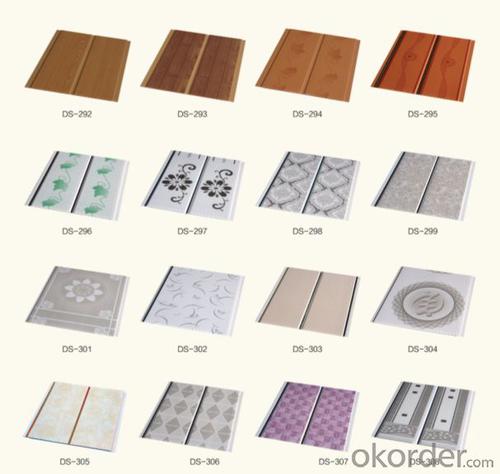

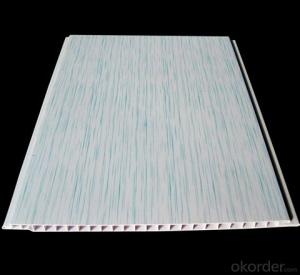

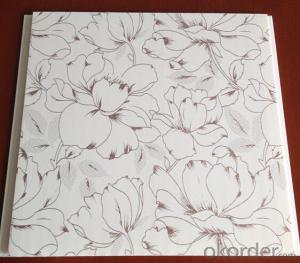

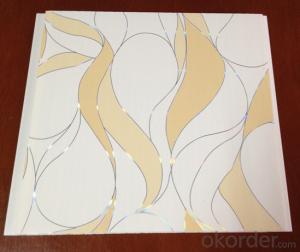

4. more than 500 colors and designs available

5. Competitive price, high quality and good service

6. Useful life more than 30years

7. Pass ISO9001-2008, Nigeria Soncap, NFPA701, B1,B2, M1,M2 and ROHS certificate

Widely Applied indoor and outdoor decoration, House Ceiling, Hotel Ceiling, Restaurant ceiling, Hospital

and school ceiling, indoor and outdoor wall decoration, etc.

Main Product Features:

(1) Where are the ceiling panel can be used?

The panels are designed for covering internal walls or ceilings in any room in the home or commercial rooms.

Especially for the wet environment, such as the kitchen and the bathroom.

(2) How can I install the panels?

Our panels are designed to be installed by the DIY’S. We also provide you with the profiles of installation,

You need very little experience and no special tools.

(3) What temperature range I can use plastic panels in?

Our decorative panels can withstand temperatures up to 140°F (60°C)

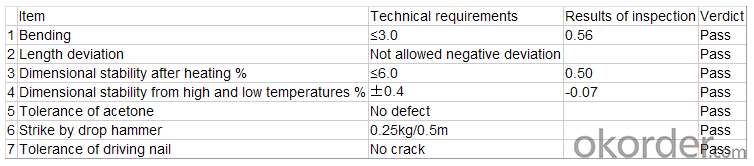

Product Specifications:

Images:

- Q: Now buy the album inside the page made of PVC board degumming, but also the phenomenon of bubbles, glue is not very sticky, looking for a good reputation, there is a big strength of the manufacturers

- First of all to give you answer the phenomenon of degumming non-stick Most of the PVC pages on the market are hot-melt adhesives, hot-melt adhesives, also known as four seasons, that is, can only be maintained for one year, a year later there will be no glue glue phenomenon, , Containing toluene, the body is not good. Low density will appear bubble deformation. Everbright album page is used with water-based pressure-sensitive adhesive, environmental protection, non-toxic and tasteless, life is not open plastic, sticky, pressurized one night, absolutely no so-called bubble phenomenon. Most of the PVC pages on the market are PP, PS coil, low density (density 1.0), easy to deformation, the board is thin, the same 100 that you know the product density is too small, soft and hard Degree, flatness, use will not work. Density determines the weight, weight determines the price, so you buy the price is certainly low, the quality is also low. Everbright album page is selected PVC sheet, good hardness, high density (density is 1.4), thickness hard, flatness is good, no deformation.

- Q: The kind of ceiling of the striped groove (pvc?) Board wall how

- Your two plans are basically abortion. Wall with solid wood wall it, the strength of some, or gypsum board.

- Q: Pvc buckle plate specifications aluminum slab board specifications are generally how much?

- Pvc buckle plate specifications aluminum slab board specifications are generally 30 * 30, 30 * 45,60 * 60. PVC gusset ceiling material, is based on polyvinyl chloride resin as the base material, adding a certain amount of anti-aging agent, modifier and other additives, by mixing, rolling, vacuum blister and other technology made.

- Q: Sun room,studded partition over the windows, pvc on the exterior. Losing heat? What can I do? Tiled roof?

- You could try painting your tiles with a paint that will help to insulate the tiles but i reckon old mate's right , you gotta get some batts in the ceiling AND walls . Just check which is going to be easier to remove the inside skin or the outside skin. If it's fibro on the outside thats what i would do. It's worth while getting a no obligation quote and seeing what the so called experts think they can do to help keep in the heat. I would also get a local handyman out of the paper and get his thoughts cos chances are he has come across similar problems before and he will probably be cheaper than what you think...

- Q: PVC sheet is not wood-based panel

- PVC sheet is not what people call the man-made board. PVC is the abbreviation of polyvinyl chloride (Polyvinyl chloride polymer = PVC), is made of vinyl chloride in the initiator of polymerization under the thermoplastic resin. Common products: pvc sheet, pvc pipe, pvc toys and so on.

- Q: How to deal with matte PVC mat noodles

- Late hot or sandblasting or chemical corrosion bar. Anyway, there are so few surface treatment

- Q: Engaged in the wedding industry, want to wedding photos (generally 60cm * 90cm or so) of the backplane into a polymer material, and now the backplane is generally made of wood, with crystal to seal the photos on the board, do not know PC board, PP board, PE board, PVC board, ABS board, etc., for which polymer material is good, mainly can not bend, not easy to deformation, hardness slightly higher, as well as consider the cost, which board is more suitable? Seeking

- Hello there! You need the material function is not bending is not easy to deformation is the need for high hardness sheet. Appeal plate is not very suitable for you, you can go to the plate market to see, 2 plate should be very suitable for you. This type of sheet is a sheet of wood processing waste scrap material recycling and other plant fiber kneading out, shape like a board, a texture, a fragrance (cover plastic taste), is very cheap

- Q: What is the difference between PVC board and oak board?

- 1.PVC plate is PVC as raw material made of cross-section of the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board. ? 2. The oak board is a kind of wood that is made of furniture or decorative material. Mainly used for making furniture.

- Q: What is the difference between pvc floor and marble floor?

- Stone is very heavy, to transport and construction to bring a lot of burden, especially for the main structure of high-rise buildings will cause great damage.

- Q: How does PVC hardness dictate?

- PVC can be divided into soft PVC and hard PVC. Soft PVC is generally used for the floor, ceiling and leather surface, but because the soft PVC contains softeners (which is the difference between soft PVC and hard PVC), easy to become brittle, easy to save, so its use has been limited. Hard PVC does not contain softener, so flexible, easy to shape, not brittle, non-toxic and pollution-free, long storage time, so it has great development and application value.

Send your message to us

PVC Ceiling in India - Proof PVC Ceilings Cmax Brand 2024 New Style Artistic Fire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords