2014 NEWES HEFEI SUDA newest engraving machine on promotion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Condition: | New | CNC or Not: | CNC | Place of Origin: | Guangdong China (Mainland) |

| Brand Name: | LuckBerry | Model Number: | R-1618*6 | Voltage: | AC380V/50Hz |

| Power(W): | 1.5kw/2.2kw | Dimension(L*W*H): | 1500*1300*180mm | Weight: | 1500kg |

| Certification: | CE/ISO | Warranty: | 12months | After-sales Service Provided: | Engineers available to service machinery overseas |

| Net weight: | 1000kg | Spindle power: | 1.5KW | Spindle speed: | 6000-24000rpm/min |

| Working area: | 1600*1800*180mm | Diameter of cutter: | 3.175-16mm | Overall size: | 1600*1800*1500mm |

| Spindle quantity: | 6pcs | Spindle mode: | Water-cooling spindle | Max working speed: | 8m/min |

Packaging & Delivery

| Packaging Detail: | Standard Package: Thickness PE Foam inside ,poly film outside, wooden pallet is optional. |

| Delivery Detail: | 30 days after receiving down payment |

Specifications

R-1618*6 CNC Engraving Machine

1.Max working speed:8m/min

2.Spindle power:1.5KW water-cooling

3.Spindle speed:6000-24000rpm

R-1618*6-SG CNC Engraving Machine

Product Description

♦ Reference Picture of R-1618*6 CNC Engraving Machine :

♦ Specification of R-1618*6 CNC Engraving Machine :

Configuration of R-1618*6 CNC Engraving Machine:

| NO. | Detail Pictures | Items | Brand |

| 1 |  | Machine Structure | Cast steel body with aging & tempering treatment, solid and durable |

| 2 |

| T-Slot Worktable | T-Slot worktable clamp the workpiece directly, suit for small piece, cutting and hollow out processing. |

| 3 |

| Water-cooling Spindle | 6pcs * 1.5kw Hanqi Water-cooling Spindle

Strong Carving power, high precision, longer service life; Adopt grinding technology, can improve the motor concentricity, prolong service life.

|

| 4 |

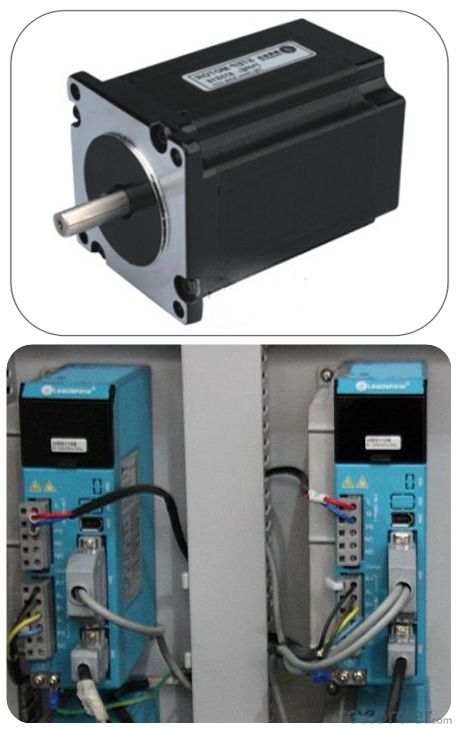

| Driving System | Leadshine Motor set with imported precision bearing, large torque, long working hours.

X,Y,Z axis drived by Leadshine driver, high resolution and positioning accuracy. |

| 5 |

| Transimission |

X,Y,Z axis adopt Taiwan AHK high precision preload anti-backlash ball screw, screw nut with tracking airtight dust removal device, guarantee the machine precision and service life.

|

| 6 |  | Guide Rail | Y axis adopt Taiwan Hiwin 20mm guide rail; X axis and Z axis adopts Taiwan Hiwin 20mm guide rail, adding scraping devices external and dust proof protection, extending the service life of the guide rail effectively. |

| 7 |

|

Electrical Component Breaker

|

Germany Schneider

|

| 8 | Frequency Inverter |

Sunfar Frequency Inverter

| |

| 9 | Electrical Compnent Cable | Special shielded cable drag chain special high flexible, can bend millions of times, drag chain support 150 degrees bend, effectively protect the cable. | |

| 11 | Approaching Sensor Switch | Dust proof, waterproof & antiseptic (3 pcs for X,Y and Z axis) | |

| 13 | Control System | Weihong System, visualization operation, real- time simulation, pretreatment ability | |

| 14 | Software Available | Artcam, Alphacam, Type 3, etc. CAD/CAM software compatible, identify G code, *.NC. | |

| 15 | Collect | 6 peice |

Workshop:

- Q: Woodworking engraving function can not be framed?

- 2.2KW high-power water-cooled inverter constant power motor, the overall casting body, "strong physique, steel special.""

- Q: What is the production flow of the woodwork door and woodworking engraving machine?

- With the continuous improvement of living standards, all kinds of furniture, door requirements are also increasing, which led to the rapid development of the whole industry to seize the opportunity, ambry woodworking engraving machine with a good stand heel, home from the door, the cabinet door started the most simple, step by step to enter the furniture industry as a whole, the right the goal of many enterprises, and in which you want to stand out, in addition to the extraordinary vision, good machine is an indispensable assistant. Here's the cabinet, woodworking engraving machine door production process.

- Q: How to use the woodworking engraving machine carved false JD carved window, set the knife road how to get, and do not understand the arc inclined lane.

- You have to draw a 5MM high arc 2D line in the 2D line to the root surface section line generating surface generated so highly as you draw 2D line height is the same, if you don't understand what I'm saying is proposed to give up because things is not a short duration of time relief drawing

- Q: Bought their own carving machine, carpentry, violin code, with a lot of knives are broken knife, serious processing, not a few will be broken

- The production of the piano code is very complicated. Cheap piano code is cheap. You can not accurately calibration and grasp the angle and internal hollowed out, it will do harm to the tone of the piano. I hope I can help you

- Q: How can the engraving machine slide the table?

- A thorough understanding of the tool setting principle of the engraving machine is of great significance for the operator to keep a clear idea of the tool, master the operation of the tool setting and put forward new tool setting methods. The aim of the tool setting is to establish the workpiece coordinate system, and the intuitive way is that the tool setting is to establish the position of the workpiece in the engraving machine workbench, in fact, it is to seek the coordinates of the tool point in the coordinate system of the worktable. For engraving machines, in order to select the tool point before machining, the tool point is the starting point of the tool relative to the workpiece when the workpiece is machined by the engraving machine. The knife point can be located on the workpiece (such as workpiece design datum or datum), can also be located in the fixture or bench, or in a fixture or a point on the table, the size must be relationship with the workpiece positioning benchmark maintaining accuracy.

- Q: What's the trouble when using a woodworking engraving machine? How to overhaul

- Woodworking engraving machine spindle motor burns:Solution: first check the pump is working, but also to see whether the lower level of circulating water.

- Q: How long can the life of a woodworking engraving machine last? If the maintenance is good!

- Woodworking engraving machine life is generally designed for about ten years.

- Q: Woodworking engraving machine to make simulation in the box

- Very simple ah, you put the knife open Weihong came up to the box to the lower left corner is cleared again inside the simulation!

- Q: Woodworking engraving machine how much money

- The main factors that affect its price are: control system, drive system, spindle type, frequency converter brand, guide rail and so on. So how much money this problem is more talk with the manufacturers.

- Q: Woodworking engraving machine does not work at the head

- The spindle motor is broken and needs to be repaired or renewed;It is possible that the inverter and other corresponding electrical parts are broken and need to be replaced

Send your message to us

2014 NEWES HEFEI SUDA newest engraving machine on promotion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords