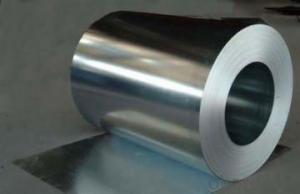

PRIME QUALITY GI STEEL COIL AND PALTE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product information:

1)Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

2)Grade : SGCD,SGCH, Q195,DX51D

3)Galvanized steel sheet /coil features:

4)Zinc coating :40-180g( as required)

5)width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

6)coil id:508mm/610mm

7)coil weight: 4-10 MT(as required)

8)surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

9)application: Structural use ,roofing, commercial use, household appliance, industry, family;

special application: Wear resistant steel, high- strength - steel plate

Technical data :

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: What is the role of steel coils in the manufacturing of pipes and tubes?

- Steel coils play a critical role in the manufacturing of pipes and tubes. They are the primary raw material used to produce these products. Steel coils are made by processing molten steel through a series of rolling mills, which shape the steel into flat, thin sheets. These sheets are then wound into coils for easy transportation and storage. In the manufacturing process of pipes and tubes, steel coils are unwound, and the flat sheets are passed through a series of machines and processes. The first step is usually to cut the steel sheets into the desired width and length. This is followed by forming the sheets into a cylindrical shape through a process called roll forming or continuous forming. The edges of the sheet are welded together to create a continuous pipe or tube. Steel coils provide several advantages in the manufacturing process. Firstly, they offer consistent and reliable quality. The production of coils ensures uniform thickness and strength throughout the entire length of the sheet, which translates to consistent properties in the final pipes and tubes. This is particularly important for applications that require high structural integrity and reliability. Secondly, steel coils allow for efficient production. The continuous supply of coils ensures a steady flow of raw material, reducing downtime and improving productivity. Coils also enable automated processes, such as roll forming, which can be highly efficient and cost-effective. Furthermore, steel coils offer flexibility in terms of size and dimensions. Coils can be produced in various widths and thicknesses, allowing manufacturers to customize the size and specifications of the pipes and tubes according to their specific requirements. This flexibility enables the production of pipes and tubes for a wide range of applications, from plumbing and construction to oil and gas pipelines. In conclusion, steel coils are the essential raw material in the manufacturing of pipes and tubes. They provide consistent quality, enable efficient production, and offer flexibility in size and dimensions. Without steel coils, the production of pipes and tubes would be significantly more challenging and less efficient.

- Q: which metals have a higher density than steel? and how does the density compare to steel( example: tungsten carbide is 2x [i think] more dense than steel.)

- This Site Might Help You. RE: what metals are more dense than steel? which metals have a higher density than steel? and how does the density compare to steel( example: tungsten carbide is 2x [i think] more dense than steel.)

- Q: How are steel coils used in the manufacturing of aerospace components?

- Steel coils are used in the manufacturing of aerospace components as they provide a reliable source of high-quality steel. These coils can be shaped, cut, and formed into various aerospace parts such as fuselage frames, landing gear, engine components, and wing structures. The strength and durability of steel make it an ideal material for withstanding the extreme conditions and stresses experienced by aircraft during flight, ensuring the safety and performance of aerospace components.

- Q: How are steel coils used in the production of electrical relays?

- Steel coils are used in the production of electrical relays as they provide the necessary magnetic field required for the relay to function. When an electric current passes through the coil, it generates a magnetic field, which then attracts or repels the relay's switch mechanism. This coil-based mechanism allows relays to control the flow of electricity in various electrical circuits.

- Q: How are steel coils labeled and identified?

- To ensure accurate tracking and handling of steel coils throughout their journey, various methods are employed to label and identify them. The labeling and identification process typically consists of the following steps: 1. Initial Marking: At the outset, the manufacturer's name or logo is affixed to the steel coil, enabling easy identification of the producing company. 2. Unique Identification Number: A distinct identification number, commonly known as a coil number, is assigned to each steel coil. This number is often engraved or imprinted on the surface of the coil and serves the purpose of tracking and managing inventory. 3. Specifications of Size and Weight: Labels indicating the size and weight specifications of the steel coils are attached. This information aids in determining the coil's dimensions and weight capacity, ensuring appropriate handling and transportation arrangements. 4. Indication of Grade and Material: The labeling typically includes information about the grade and material composition of the steel coil. This essential data offers insights into the properties and quality of the steel, guaranteeing its correct utilization in manufacturing processes. 5. Heat or Lot Number: Steel coils may also bear a heat or lot number, which denotes the production batch from which the coil originated. This information contributes to traceability and quality control, simplifying identification in the event of any issues or defects. 6. Barcodes or QR Codes: Many steel coils now feature barcodes or QR codes that can be scanned using automated systems. These codes contain all pertinent information about the coil, streamlining data capture and management throughout the supply chain. Proper labeling and identification of steel coils are of utmost importance for efficient logistics management, inventory control, and quality assurance. By implementing these identification methods, manufacturers, distributors, and end-users can effortlessly track, handle, and utilize steel coils in a secure and productive manner.

- Q: what is the densest type of steel ? what is its density ?what is its tensile strength .

- Technically, any metal that is not pure could be considered a steel alloy with the addition of iron. Density will vary depending on the percentage of each alloying element. In commonly available alloys, those with a high percentage of nickel will be the most dense. Nickel has a high molecular weight and readily alloys with most other metals. This class of materials is stainless steels, heat resistant super alloys such as inconel, hastalloy, etc. Tensile strength is not directly related to nickel content. Elements such as boron, manganese, molybdenum, and chromium have the most effect on tensile strength in steel alloys both as rolled and heat treated. Hope that answers your question.

- Q: what are the characteristics when of iron or steel when stretched? which one could be stretched further? which one stretches more evenly?thankyou

- Technically, this is known as ductility. a material which can be permanently bent and stretched is said to be ductile. Pure iron, when it lacks carbon and impurities like sulfur and phosphorus, is relatively soft, ductile, and weak. It's about as soft as brass. It can be stretched to about 50% of it's original length before it breaks. The amount a sample can be stretched without breaking is known as elongation. The key to steel is the addition of about 2 parts per thousand of carbon, or around 0.2%. This alters the crystal structure and makes steel much harder, stronger, and tougher, though it also becomes somewhat less ductile. Mild steel, with a low carbon content, has an elongation of around 30% Adding more carbon makes the steel yet stronger, but further reduces the elongation. Adding more than 2-3% carbon produces what is known as Cast Iron. Cast iron is brittle. It has virtually no ductility. It's pretty cheap to produce though.

- Q: Aluminum alloy rolling doors and color steel shutter door that good

- Among them, aluminum alloy rolling doors and ordinary rolling doors, both from the appearance, environmental protection or safety, have considerable advantages. Aluminum Alloy doors can be sprayed on the surface of various colors and patterns, but also with the concavity of the wood, sand grain coated, highlight the noble temperament, improve grades, if it is used in shops, you can let your talent shows itself in many shops in the.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws as they serve as the raw material for manufacturing the screws. The steel coils are unwound and fed into a machine that cuts and shapes the steel into the desired screw form. This process ensures that the screws are made from high-quality steel and have the necessary strength and durability.

- Q: if someone wanted to melt cast steel or iron into small-relatively simple shapes such as rod-tapered rod-or etc... how would you go about melting the steel/iron what would the mold need to be made of?

- Sand casting useing silica sand was the classical method. Wood models called patterns made the cavity into which the metal was poured. Furnaces capable of melting iron and steel are not found everywhere. They are industrial machinery, not to be improvised. Some-one had better be very careful if he does get access to molten steel. There are some aspects of the process that are not intuitively obvious that can 'bite you' badly. Get at least some briefing from an experienced foundryman.

Send your message to us

PRIME QUALITY GI STEEL COIL AND PALTE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords