Prime Quality 3003 Aluminum Coil, 3003 Aluminum Roll - Aluminum Sheets in Ohio

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

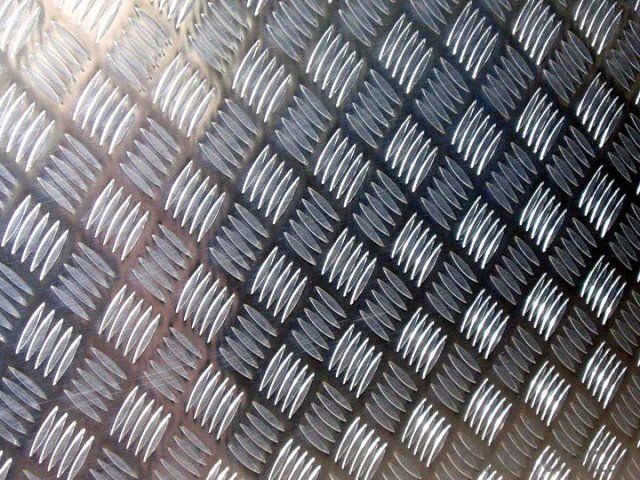

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: I am thinking about getting a MacBook Aluminum or a MacBook white. The Aluminum is 2.0 GhZ and the MacBook White is 2.16 GhZ. which should i get? also i am really wondering if you can upgrade the processors in both MacBooks..... Please give me link if you can. THANKS!!

- The aluminum will definitely be faster than the white one assuming those clock speeds are accurate. The 2.16 is an older model with an early Core 2, slower RAM, and a much slower video card. And you cannot swap the CPU in any of Apple's laptops made over the past decade or so.

- Q: are there any carbonated mineral water that are produced in aluminium cans.

- Aluminium cans have an oxide covering on them so the reaction between them and the carbonated water is so little if any that it can't be noticed. Aluminium is also not so high on the reactivity series

- Q: Is it possible to substitute traditional wooden windows and doors with aluminum sheets?

- <p>Yes, you can use aluminum sheets to replace traditional wooden windows and doors. Aluminum is a popular choice due to its durability, low maintenance, and resistance to weather and pests. It also offers good thermal performance and can be designed to mimic the appearance of wood. However, it's important to consider factors like insulation, cost, and the specific design requirements of your project before making the switch.</p>

- Q: How do you ensure the surface quality of aluminum sheets?

- To guarantee the surface quality of aluminum sheets, manufacturers can take several steps: 1. Cleanliness is crucial. Prior to any surface treatment or inspection, it is vital to thoroughly clean the aluminum sheets and eliminate any dirt, grease, or contaminants. This can be accomplished using solvents, detergents, or specialized cleaning agents. 2. A visual inspection is necessary. Trained personnel should visually inspect the surface for visible flaws such as scratches, dents, or pitting. Proper lighting and magnification tools should be utilized. 3. Chemical treatments may be required. Depending on the desired surface finish and application, aluminum sheets may undergo chemical treatments such as anodizing, chromate conversion coating, or passivation. These processes can enhance the sheets' surface quality, corrosion resistance, and aesthetic appearance. 4. Mechanical polishing can be employed. To eliminate surface imperfections and achieve a smooth, glossy finish, mechanical polishing techniques like grinding, buffing, or sanding can be utilized. It is important to maintain consistency and avoid over-polishing, which can compromise the integrity of the sheets. 5. Coating and protection are essential. Applying protective coatings like lacquers, paints, or powder coatings can further improve the surface quality, appearance, and durability of aluminum sheets. These coatings act as a barrier against corrosion, abrasion, and environmental factors. 6. Quality control is crucial. Rigorous quality control procedures should be implemented throughout the manufacturing process. Regular inspections, testing, and documentation should be conducted to ensure that the surface quality of aluminum sheets meets the required standards and specifications. 7. Proper handling and packaging are necessary. To prevent surface damage during transportation and storage, it is important to handle and package the sheets correctly. Protective measures such as using protective films, paper interleaves, or cushioning materials should be employed to safeguard the surface quality until the sheets reach their final destination. By following these measures, manufacturers can ensure that the surface quality of aluminum sheets meets the desired specifications and exceeds customer expectations.

- Q: Are 101 aluminum sheets suitable for cryogenic applications?

- Cryogenic applications are not suitable for 101 aluminum sheets. Although aluminum is generally a good choice for low-temperature environments because of its low thermal conductivity and high strength-to-weight ratio, 101 aluminum is not specifically designed to endure the extreme temperatures associated with cryogenic applications. In cryogenic applications, materials like aluminum alloys (for example, 5083 or 6061) or specialized cryogenic alloys like stainless steel or titanium are commonly used. These materials possess improved properties that allow them to handle the extreme cold temperatures without compromising their structural integrity. Therefore, it is advisable to use materials specifically designed for cryogenic applications to ensure optimal performance and safety.

- Q: Explain the distinction between aluminum sheets based on their thickness.

- <p>Aluminum sheets with different thicknesses primarily differ in their strength, weight, and applications. Thicker sheets offer greater strength and rigidity, making them suitable for structural applications or heavy-duty uses. In contrast, thinner sheets are lighter and more flexible, ideal for applications requiring formability or where weight is a concern, such as in the automotive or aerospace industries. The choice of thickness depends on the specific requirements of the project, including load-bearing needs, durability, and aesthetic considerations.</p>

- Q: I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- This Site Might Help You. RE: Why should we recycle aluminium? I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by... Thanks a lot this will help me loads. P.S this is just a report for my science project.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum has excellent thermal conductivity and is lightweight, making it a suitable material for transferring heat efficiently in heat exchangers. Its corrosion resistance and durability also make it a popular choice in various heat exchange applications.

- Q: What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- Aluminum Bonds

- Q: Are aluminum sheets prone to warping?

- Under certain conditions, aluminum sheets may be susceptible to warping. Unlike steel, aluminum is a relatively soft metal, making it more prone to bending or distorting. However, the extent of warping in aluminum sheets depends on various factors, including sheet thickness, alloy composition, temperature exposure, and applied stress levels. Thinner aluminum sheets have less structural integrity, making them more prone to warping. Conversely, thicker sheets are more resistant to warping due to their increased rigidity. The specific alloy composition of the aluminum sheet also affects its susceptibility to warping. Warping can occur due to temperature fluctuations. High temperatures cause aluminum to expand, and without proper support, it may bend or warp. Similarly, rapid cooling causes contraction, leading to warping. The level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can deform the sheet. To minimize warping, it is crucial to handle aluminum sheets carefully, provide adequate support during temperature changes, and avoid applying excessive stress. Additionally, using thicker sheets or selecting alloys with higher tensile strength helps reduce the risk of warping.

Send your message to us

Prime Quality 3003 Aluminum Coil, 3003 Aluminum Roll - Aluminum Sheets in Ohio

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords