High Adhesiveness and Preciseness Prepainted Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Prepainted Steel Sheet1.Common polyester paint

2.50-150g/m2 dipped layer

3.2 Coating 2 Baking process

4.Long life span

Prepainted Steel Sheet

Brief Introduction

1. Prepainted Steel Sheet is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Prepainted Steel Sheet consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated. The finish coats of Prepainted Steel Sheets can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

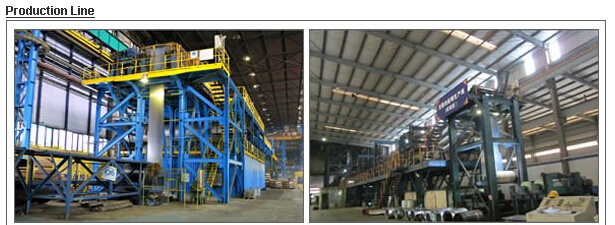

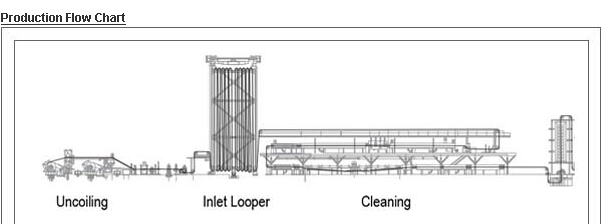

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Prepainted Steel Sheet has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Prepainted Steel Sheets can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

- Q: How do steel products contribute to the renewable energy sector?

- Steel products contribute to the renewable energy sector in various ways. Firstly, steel is used in the manufacturing of wind turbines, providing structural integrity and support for the blades and towers. Additionally, steel is used in the construction of solar panels, ensuring durability and longevity. Furthermore, steel is utilized in the transmission and distribution infrastructure for renewable energy, such as power lines and grid systems. Overall, steel products play a vital role in the development, installation, and maintenance of renewable energy technologies, enabling the sector to flourish and reduce reliance on fossil fuels.

- Q: How is steel produced?

- Steel is produced through a process called steelmaking, which typically involves the combination of iron ore, coal, and limestone in a blast furnace. The iron ore is first mined and then refined into iron through a series of heating and cooling processes. The refined iron is then combined with coal and limestone in the blast furnace, where it is heated to extreme temperatures to remove impurities and convert it into molten iron. This molten iron is then further processed to remove any remaining impurities and adjust its carbon content to create different grades of steel.

- Q: What are the different types of steel railway products available?

- There are various types of steel railway products available, including rails, sleepers, fastenings, and switches. Rails are the main component of railway tracks, typically made of steel and available in different profiles and lengths. Sleepers, also known as ties, are laid underneath the rails to support them. Fastenings, such as clips, bolts, and plates, secure the rails to the sleepers. Switches, or turnouts, allow trains to change tracks, and they consist of movable components made of steel.

- Q: What are the different types of steel roofing materials?

- There are several types of steel roofing materials available, including corrugated steel, standing seam steel, and stone-coated steel.

- Q: How is steel used in the production of construction machinery and equipment?

- Steel is widely used in the production of construction machinery and equipment due to its strength, durability, and ability to withstand heavy loads. It is utilized in various components such as frames, chassis, buckets, and booms, providing the necessary structural integrity and stability required for these machines to operate effectively in demanding construction environments. Additionally, steel's versatility allows for easy fabrication and customization, enabling manufacturers to create complex and intricate designs that meet specific requirements.

- Q: How are steel products used in the construction of disaster management and emergency response centers?

- Steel products are widely used in the construction of disaster management and emergency response centers due to their strength, durability, and versatility. Steel is used for structural components such as beams, columns, and frames, providing the necessary support and stability required to withstand potential disasters or emergencies. Additionally, steel is used for roofing, walls, and doors, ensuring the buildings are secure and able to withstand extreme weather conditions. The use of steel in construction also allows for faster and more efficient assembly, which is crucial in emergency situations where time is of the essence. Overall, steel products play a vital role in creating resilient and reliable structures for disaster management and emergency response centers.

- Q: How is steel sheet metal formed?

- Steel sheet metal is formed through a process called cold rolling, where the steel is passed through a series of rollers to reduce its thickness and increase its length. This process allows for the creation of thin and flat sheets of steel that are used in various industries for manufacturing purposes.

- Q: How is steel billet produced?

- Steel billet is produced through a process called continuous casting, where molten steel is poured into a water-cooled mold to form a solid rectangular shape. Once solidified, the billet is then further processed through reheating and rolling processes to achieve the desired size and shape for various steel products.

- Q: What are the different types of steel bars and their applications?

- There are several different types of steel bars, each with its own unique properties and applications. Some common types include round bars, square bars, flat bars, and hexagonal bars. Round bars are often used in construction, engineering, and manufacturing industries for applications such as shafts, fasteners, and machinery components. Square bars are commonly used in construction, fabrication, and manufacturing projects, particularly for making structural supports and frames. Flat bars are versatile and widely used in applications such as braces, brackets, and trim work. Hexagonal bars are often utilized in machinery and equipment manufacturing. Overall, the specific type of steel bar chosen depends on the intended application and the desired characteristics necessary for that particular use.

- Q: What are the advantages of using steel plates in manufacturing?

- There are several advantages of using steel plates in manufacturing. Firstly, steel plates are highly durable and have a high strength-to-weight ratio, making them suitable for heavy-duty applications. Secondly, steel plates have excellent corrosion resistance, reducing the risk of rust and increasing the lifespan of the manufactured product. Additionally, steel plates can be easily fabricated and modified to meet specific design requirements, providing flexibility in manufacturing processes. Lastly, steel plates offer superior heat resistance, making them ideal for applications that involve high temperatures or thermal stress.

Send your message to us

High Adhesiveness and Preciseness Prepainted Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords