PRIME GALVANIZED STEEL COIL

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized steel coil

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

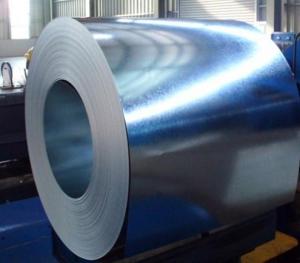

Commodity | Hot dip galvanized steel coil |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143/ GB/T 2518 |

Grade | DX51D/ S250,280,320GD,SGCC,SGHC,SGH340,SGH400,SGH440,G450,G550 |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 900mm/1000mm/1219mm/1200mm/1220mm/1250mm |

Thickness | 0.2mm~4.0mm |

Type of coating: | galvanized |

Zinc coating | Z40-275g/m2,Z40-Z450g/m2 |

Surface treatment | chromed / skinpass/ oiled/slightly oiled/ dry/ |

Surface structure: | zero spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-10/MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | home appliances, constructions, building, machineries |

Price terms | FOB,CFR,CIF |

Payment terms | T/T,L/C |

delivery time | 25~40days after deposit or the receipt the L/C |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test |

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

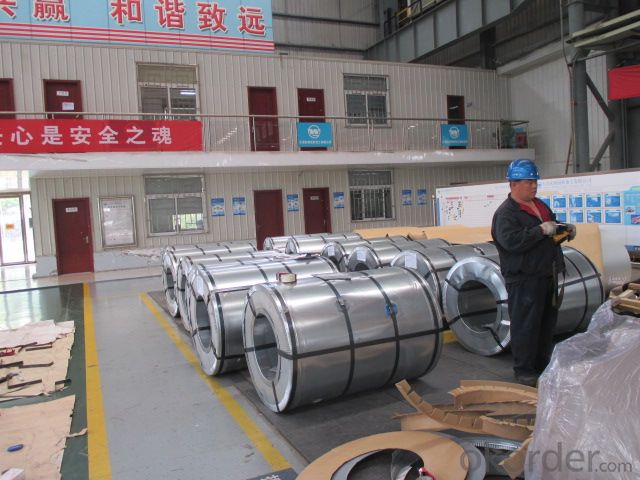

Our Production Line:

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of products

Our Application

- Q: How is steel wire rope manufactured?

- Steel wire rope is manufactured through a process called wire drawing. It starts with raw steel wire being drawn through a series of dies to reduce its diameter and increase its strength. This wire is then twisted together to form strands, which are further twisted around a core to create the final rope. These ropes undergo heat treatment and various tests to ensure their quality and durability.

- Q: How is steel wire used in the production of suspension systems for vehicles?

- Steel wire is used in the production of suspension systems for vehicles as it provides strength, durability, and flexibility required to absorb shocks and maintain stability during vehicle movement. It is commonly used to create springs, such as coil springs, which help support the weight of the vehicle and provide a smoother ride by absorbing vibrations and impacts from uneven road surfaces. Additionally, steel wire is used in the production of sway bars, which help reduce body roll and improve overall handling and stability of the vehicle.

- Q: How is steel used in the construction of railway stations and terminals?

- Steel is a crucial material in the construction of railway stations and terminals as it is used for various structural components such as beams, columns, and trusses, providing strength and stability to the buildings. It is also used in the fabrication of platforms, staircases, and canopies, ensuring durability and safety for passengers and staff. Moreover, steel is employed in the construction of railway tracks and platforms, providing a sturdy foundation for the movement of trains and facilitating efficient transportation.

- Q: What are the different types of steel gratings and walkways available?

- There are several different types of steel gratings and walkways available, including standard welded steel gratings, pressure-locked gratings, riveted gratings, and heavy-duty gratings. These gratings come in various designs and sizes to cater to different applications and load requirements. Additionally, there are also different surface finishes available, such as galvanized, painted, or untreated, depending on the desired level of corrosion resistance and aesthetic appeal.

- Q: What are the different types of steel scaffolding systems?

- There are several different types of steel scaffolding systems, including tube and coupler scaffolding, frame scaffolding, modular scaffolding, and suspended scaffolding.

- Q: How is steel used in the construction of shopping malls and retail centers?

- Steel is commonly used in the construction of shopping malls and retail centers due to its strength, durability, and versatility. It is used in various structural elements such as beams, columns, and frames, providing stability and support to the buildings. Steel is also used in the construction of roofs, walls, and facades, offering design flexibility and aesthetic appeal. Additionally, steel is often utilized in the construction of escalators, staircases, and elevators, ensuring efficient vertical transportation within these commercial spaces.

- Q: What are the factors to consider when selecting the right type of steel for a specific application?

- When selecting the right type of steel for a specific application, there are several factors to consider. These include the required strength and hardness, corrosion resistance, weldability, formability, and cost. Additionally, factors such as the environment in which the steel will be used, the load-bearing requirements, and any specific industry standards or regulations must also be taken into account. Overall, a thorough understanding of the application's requirements and careful consideration of these factors will ensure the selection of the most suitable type of steel.

- Q: How are steel products used in the automotive industry?

- Steel products are widely used in the automotive industry for various purposes, including the construction of car bodies, chassis, and engine components. Steel provides strength, durability, and crash resistance, ensuring the safety of passengers. It is also used for manufacturing components like suspension systems, exhaust systems, and various other parts due to its high tensile strength and resistance to corrosion.

- Q: How are steel products used in the construction of high-rise buildings?

- Steel products are commonly used in the construction of high-rise buildings due to their strength, durability, and versatility. They are used for structural components such as beams, columns, and frames, providing the necessary support and stability to withstand the weight and forces exerted on the building. Additionally, steel is often used for cladding, roofing, and façades, offering aesthetic appeal and protection against weather elements. Its flexibility allows for easy customization and modifications, making it an ideal material for constructing tall buildings efficiently and safely.

- Q: How are steel bars used in the reinforcement of bridges and flyovers?

- Steel bars are used in the reinforcement of bridges and flyovers to enhance their structural integrity and strength. These bars, also known as rebars, are embedded within the concrete to provide tensile strength and resist the forces exerted on the structures. By reinforcing the concrete, steel bars help distribute the load more efficiently, preventing the bridge or flyover from collapsing under heavy traffic or external forces.

Send your message to us

PRIME GALVANIZED STEEL COIL

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords