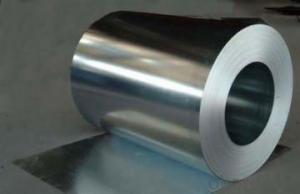

Prime Galvalume steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Technical data :

Hot dipped galvanized coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

|

|

|

|

|

| |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: Hello,is it possible to divide an alloy in its own elements? I am particularly interested in Stainless Steel, which is made of Nickel, Chrome and Iron. Do you have an idea of where can I find some more information (blogs, reviews, sites or books)?Thanks for your help

- The iron ,nickel and chromium are (mainly) in solid solution with one another -- all the atoms are completely intermixed on the (FCC)crystal lattice . If you heat stainless steel until it melts , you will simply have a liquid solution of all the components --the components do not separate out. The only practical way to separate the metallic elements would be to make use of their differing reactivities -- re their oxides , nitrides , carbides etc -- and then gradually refine their compounds .

- Q: Molten steel changes to solid steel at its __________ point. Could you please fill in the blank? Thank you so much, it is greatly appreciated. I have been looking for the answer to this question for a long time, but I never understand what the websites are trying to say because I don't have that big of a vocabulary and don't know what they mean. I've seen things saying steel boiling point, steel melting point, and steel freezing point. I don't know what any of those mean, and they might be the answer. Please help me. Thank you.

- Carbon 'tempers' steel, by making it harder and less prone to bending (ductility). It fits the carbon atoms into the spaces in between the crystal lattice structure of the iron atoms. Too much carbon means the steel becomes more brittle, harder to weld and thus more likely to shatter under stresses which are perpendicular (shear forces) to the crystal structure of the molecules. It also is very difficult to work, requiring very high temperatures.

- Q: I don't know it is low alloy steel or high allow steel or medium carbon steel

- Yes,30CrNiMo8 is a high grade alloy steel. *These steels generally contain higher carbon concentration (0.25%). As they are hardenable their mechanical properties can be tailored to specific needs by suitable adjustment of the annealing temperature. Finished products can be hardened to have a high surface hardness in combination with a tough and ductile core. The mechanical properties increase with increasing carbon concentration. Cr and Ni add additional improvements in properties. The Mn grades are a little cheaper. V and Mo add improved temperature resistance. The grades Cxx are developed for less stringent quality requirements but are cheaper.

- Q: What are the different methods of heat treatment for steel coils?

- There are several different methods of heat treatment for steel coils, each with its own benefits and applications. 1. Annealing: This method involves heating the steel coils to a high temperature and then slowly cooling them, usually in a controlled atmosphere. Annealing helps to relieve internal stresses, improve ductility, and refine the grain structure of the steel, making it softer and more machinable. 2. Normalizing: Normalizing is similar to annealing, but the cooling process is typically faster. This treatment is often used to refine the grain structure and achieve a more uniform hardness throughout the steel coils. It also helps to remove any residual stresses and improve the mechanical properties of the material. 3. Quenching and tempering: In this two-step heat treatment process, the steel coils are first heated to a high temperature and then rapidly cooled by immersion in a quenching medium, such as oil or water. This causes the formation of a hard, brittle phase called martensite. To improve the toughness and reduce the brittleness, the coils are then reheated to a lower temperature and held there for a specific period of time. This process, known as tempering, helps to reduce the internal stresses and increase the ductility and toughness of the steel. 4. Case hardening: Case hardening is a heat treatment method used to increase the surface hardness of the steel coils while maintaining a relatively soft and ductile core. The process involves heating the coils in the presence of a carbon-rich atmosphere, allowing carbon to diffuse into the surface layer of the steel. This creates a hard outer layer, known as the case, while preserving the desired mechanical properties in the core. 5. Stress relieving: Stress relieving is performed by heating the steel coils to a specific temperature and holding them there for a sufficient period of time. This process helps to reduce residual stresses that may have been introduced during previous manufacturing or heat treatment processes. Stress relieving can improve dimensional stability, reduce the risk of distortion or cracking, and enhance the overall performance of the steel coils. Overall, the choice of heat treatment method for steel coils depends on the desired properties, intended application, and specific requirements of the end product. Each method has its own advantages and can be tailored to achieve the desired balance between hardness, toughness, ductility, and other mechanical properties.

- Q: What are the different methods of protecting steel coils from corrosion?

- There are several methods for protecting steel coils from corrosion. One common method is applying a protective coating, such as zinc or epoxy, which acts as a barrier between the steel surface and corrosive elements. Another approach is using corrosion inhibitors, which are chemicals that can be added to the storage environment or applied directly to the steel to reduce the rate of corrosion. Additionally, proper storage conditions, such as controlling humidity levels and preventing exposure to moisture and chemicals, can also help protect steel coils from corrosion.

- Q: Can steel coils be coated with fire-resistant materials?

- Yes, steel coils can be coated with fire-resistant materials.

- Q: What are the different methods of coil slitting for precision cuts?

- There are several methods of coil slitting for precision cuts, including rotary slitting, loop slitting, and double knife slitting. Rotary slitting involves using a circular blade to cut through the coil, while loop slitting utilizes a looping mechanism to create tension and then cuts the coil with a straight blade. Double knife slitting, on the other hand, employs two blades that move in opposite directions to cut the coil. These methods enable precise and efficient cutting of coils into narrower strips for various industrial applications.

- Q: I like non-stick cookware but it dont hold up no matter how much money you spend. What isthe best kind? Is there something better then stainless steel or iron skillet? I do not care if I have to use extra elbow grease to clean a pan.

- I have a combination of them both. I have Le Creuset enameled cast iron dutch-ovens, pots and pans; as well as All Clad stainless steel saute and deep-rimmed pans which have a copper core. I have one non-stick pan that I use for cooking eggs in.

- Q: What are the common coil storage conditions?

- Common coil storage conditions include keeping the coils in a dry and well-ventilated area, away from direct sunlight and moisture. It is also important to store the coils in a clean and organized manner, preferably on pallets or racks, to prevent damage or deformation. Additionally, maintaining a stable temperature and humidity level is crucial to minimize the risk of corrosion or other forms of deterioration.

- Q: What are the common coil coating materials?

- The common coil coating materials include polyester, polyvinylidene fluoride (PVDF), polyurethane, epoxy, and acrylic.

Send your message to us

Prime Galvalume steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords