Prime Cold Rolled Steel Coils with Low Price China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,JIS

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Oiled,Bright

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B

Certification:

ISO,SGS,BV,CE

Thickness:

0.18mm-1.8mm

Width:

1000mm-1600mm

Length:

requirement

Outer Diameter:

according to weight

Net Weight:

10MT

Packaging:

Standard Export Packing

| Main Quality Standard | JIS3141, EN10130, DIN1623, ASTM A1008/1008M GB5213 |

| Annealing Type | 20 hydrogen annealing furnaces from Austria EBNER |

| Specification | 0.25mm upto 1.2mm ×900mm upto 1265mm |

| Weight | max 10,000kg |

| Yield Strength | 100 Mpa upto 280 Mpa |

| Products inside Diameter | φ508mm or φ610mm |

| Outer Diameter | max φ2,050mm |

| Packing | export standard packaging; horizontal packaging |

| Capacity | 300,000 tons/year |

Export standard seaworthy packaging

· Axial and circumferential steel straps with seal (4 steel straps each)

· VCI Anti-rust kraft paper

· Water-proofing plastic

· Pearl wool (coil surface)

· Steel cover (coil surface/bore)

· Plastic cover (coil sides)

· Inside and outside corner protectors

The reasons why customers choose us

1.High quality raw material

Our raw material is bought from some famous state-owned steel mills,such as WISCO,Baosteel,Ansteel,Tangsteel,etc.

2.High-precision thickness

The thickness tolerance can be reached +/-0.01mm.

The zinc layer mass range is from 30g/m2 to 275g/m2.

3.Customer-oriented concept

We try our best to find the solutions for customers and finnally meet their needs.

4.Advaned equipment and strict quality inspection

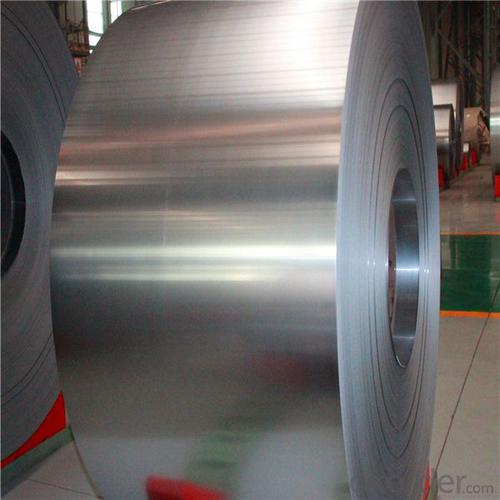

PRODUCT PICTURE

- Q: How do steel coil manufacturers stay updated with industry trends?

- Steel coil manufacturers utilize various methods to stay informed about industry trends: 1. Attending industry conferences and trade shows allows manufacturers to connect with other professionals, attend seminars and presentations, and learn about the latest trends and innovations in the steel coil industry. 2. Subscribing to industry publications and magazines provides manufacturers with regular updates on trends, market insights, and technological advancements in the steel coil industry. These publications often feature articles and interviews with experts, delivering valuable information to stay updated. 3. Actively participating in online forums, discussion boards, and social media groups dedicated to steel coil manufacturing helps manufacturers stay connected with the industry. These platforms allow them to engage with peers, share knowledge, ask questions, and stay updated on the latest trends. 4. Maintaining close relationships with suppliers and customers enables manufacturers to gain insights into changing market demands, new product requirements, and emerging trends. Suppliers and customers often share information about industry trends and advancements that assist manufacturers in adapting their processes accordingly. 5. Investing in continuous education and training programs for employees ensures that the workforce remains updated on the latest industry trends, technological advancements, and best practices. Prioritizing employee development equips manufacturers with the skills and knowledge necessary to stay ahead of the curve. 6. Allocating resources for research and development activities allows steel coil manufacturers to explore new materials, manufacturing techniques, and technologies. By investing in R&D, manufacturers can stay at the forefront of industry trends and develop innovative solutions that meet evolving customer demands. 7. Staying updated with government regulations, industry standards, and certifications that impact the steel coil industry is crucial. Compliance with these regulations often requires manufacturers to adopt new practices, technologies, or materials, ensuring that they remain up to date with the latest trends and requirements. By actively engaging in these activities, steel coil manufacturers can stay informed about industry trends, emerging technologies, and market demands. This enables them to adapt their processes, products, and strategies to remain competitive and meet the evolving needs of their customers.

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment as they are shaped and formed into various components such as pipes, tubes, and fittings. These coils provide the necessary strength, durability, and corrosion resistance required for the harsh operating conditions in the oil and gas industry. Additionally, steel coils are often used in the fabrication of storage tanks, pressure vessels, and offshore platforms, ensuring the safe and efficient extraction, processing, and transportation of oil and gas resources.

- Q: What are the common methods of storing steel coils in warehouses?

- The common methods of storing steel coils in warehouses include stacking them on pallets or racks, using coil cradles or coil saddles to hold them in place, or utilizing specialized coil storage systems such as coil racks or coil cranes.

- Q: What is the typical size and weight of a steel coil?

- The specific application and industry play a role in determining the varying size and weight of a steel coil. Generally, steel coils are manufactured with widths that range from 0.5 to 2 meters (1.6 to 6.6 feet) and can weigh anywhere between 1 to 25 metric tons (2,205 to 55,116 pounds). The size and weight of a steel coil are influenced by factors such as the type of steel utilized, the intended purpose of the coil, and the manufacturing method employed.

- Q: How are steel coils processed for cold rolling or hot rolling?

- Steel coils are first unwound and inspected for any defects. Then, they are cleaned and treated to remove any impurities. For cold rolling, the coils are passed through a series of rollers at room temperature to reduce their thickness and improve their surface finish. On the other hand, for hot rolling, the coils are heated to high temperatures and then passed through rollers to achieve the desired thickness and shape.

- Q: Which movie is better and why?I say Man of Steel!

- Captain America

- Q: every time i look for steel over the internet like to build cars motorcycles ect i only get steel pipes where can i get steel sheets

- This okorder /... Most towns have a steel supply house/ business, check your yellow pages. Also check with local welding and machine shops. They can give you ideas and or their suppliers. They often have bits and pieces that you might buy, instead of ordering a full sheet of material. Wingman

- Q: Can steel coils be custom-made to specific requirements?

- Yes, steel coils can be custom-made to specific requirements. Steel manufacturers have the capabilities to produce steel coils with various dimensions, thicknesses, and specifications to meet the specific needs of customers. These coils can be customized in terms of width, length, weight, and even surface finish to suit specific applications and industries. Customization can also include variations in steel grade, coating type, and mechanical properties to ensure the desired performance and functionality. The ability to tailor steel coils to specific requirements allows for optimal utilization in various sectors such as automotive, construction, appliances, and manufacturing, among others.

- Q: How are steel coils inspected for flatness using optical sensors?

- The process of inspecting the flatness of steel coils involves the use of optical sensors, which are part of a system known as optical flatness measurement. This system employs high-resolution cameras to capture images of the steel surface as it passes through the inspection line. To begin, the steel coil is unwound and conveyed over a roller table. While in motion, the optical sensors are positioned above the coil to capture images at regular intervals. These sensors are typically a combination of laser line projectors and high-resolution cameras. The laser line projectors emit a thin, straight line of laser light across the width of the steel coil. This laser line serves as a reference plane for measuring the flatness of the steel surface. Subsequently, the high-resolution cameras capture images of the laser line interacting with the steel coil. The captured images are then subjected to analysis using advanced image processing algorithms. These algorithms examine the deformation of the laser line on the steel surface and calculate the deviations from the flat reference plane. These deviations indicate any irregularities or variations in the flatness of the steel coil. The optical sensors possess the capability to accurately detect even the most minute deviations in flatness, measuring them in micrometers or smaller units. This enables manufacturers to identify and correct any flatness issues in the steel coils before further processing or shipment. In addition to measuring flatness, optical sensors can also identify other surface defects such as waviness, scratches, or dents. By incorporating multiple cameras and laser line projectors from different angles, a comprehensive inspection of the steel coil's surface can be achieved. Overall, the utilization of optical sensors for inspecting steel coil flatness offers a swift, precise, and non-contact method. By identifying and addressing any flatness issues early in the production process, manufacturers can guarantee the delivery of top-quality steel products to their customers.

- Q: What are the current trends in the steel coil industry?

- Some current trends in the steel coil industry include an increased focus on sustainability and environmental impact, the adoption of advanced technologies for improved efficiency and productivity, growing demand for high-strength and lightweight steel coils for automotive and construction sectors, and the emergence of new markets in developing countries. Additionally, there is a shift towards digitalization and automation in order to streamline operations and reduce costs.

Send your message to us

Prime Cold Rolled Steel Coils with Low Price China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords