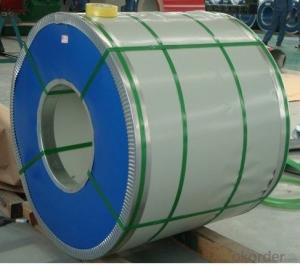

Prepainted gavanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Type: | Technique: | Surface Treatment: | |||

| Application: | Width: | Length: | |||

| Zinc coating: | MOQ: | Product: | |||

| Website: | Company: |

Packaging & Delivery

| Packaging Detail: | Fully seaworthy export packing with paper tube Each coil is wrapped in water-proof paper. As client request. |

| Delivery Detail: | Within 15 days or as order quantity. |

Specifications

color coated galvanized steel coil

Standard: ASTM, AISI, BS, DIN, GB

Width: 750-1250mm

Thickness: 0.35mm

Advantages of color coated steel coil:

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of color coated steel coil:

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

- Q: Hi, I live in the Boston area and I'm trying to find a steel suppler that can provide mild steel for hobby welding. I can go through my job, but we only put in orders every couple of months so it's not very convenient. Also, the few suppliers I've found only sell in bulk. So if anyone knows where I can angle irons, flat bars, sheets, etc... by the piece it would greatly appreciated. Thanks

- They will sell any quantity of metal and even cut it to size - my experience has been that their prices are not wildly out of line for single pieces of full length stock compared to buying singles where you have to buy a minimum. They also may have sizes that ordinary places consider odd. I was looking for 5/8 square 16 gauge and was told it would have to be shipped in from Houston (to Dallas) by my nearest supplier and found it in stock at MetalSM. But check if you get something odd - the 5/8 cost more than 3/4 at both places and MetalSM actually gave me 3/4 but took it back even though I had cut it. Also check the regular steel suppliers in your area as well as retail welders metal supply places.

- Q: Suppose that the hardness of steel is uniformly distributed, taking on values between 50 and 80 on the Rockwell B scale.Compute the probability that the hardness of a randomly selected steel specimen is less than 60. a..462b..333c..500d.2e..750 Question 8 Refer to question 7. Compute the probability that the hardness of a randomly selected steel specimen is between 70 and 75.a..167b..500c..063d..100e..

- Suppose that the hardness of steel is uniformly distributed, taking on values between 50 and 80 on the Rockwell B scale. That would be... f(x) = 1/(80 - 50), 50 ≤ x ≤ 80 . . . . . 0 elsewhere Consider this following problem.. Compute the probability that the hardness of a randomly selected steel specimen is less than 60. Here, we have... P(x 60) Oh! Know that the mean and the standard deviation of the uniform distribution function are... ? = (a + b)/2 σ = (a - b)?/12 You should get... ? = 65 σ = 75 Now... P(z (60 - 65)/75) = P(z -0.07) Hence, you should get around 0.462. Good luck!

- Q: Climbing ropes used by mountaineers are usually made of nylon. Would steel cable of equal strength as the nylon be just as good? What advantages and disadvantages would it have compared to the nylon?

- steel is NOT as flexible and much slipperier if you fall the nylon stretches to slow the victim but a steel cable would stop short and kill you

- Q: How do steel coils perform in high-pressure applications?

- Due to their robust and durable nature, steel coils are highly effective in high-pressure scenarios. The exceptional tensile strength of steel enables it to endure immense pressure without any distortion or breakdown. Moreover, steel coils are specifically engineered to retain their shape and structural integrity even under the most extreme pressure, making them ideal for deployment in a wide range of high-pressure applications such as hydraulic systems, pressure vessels, and industrial machinery. Furthermore, the exceptional resistance of steel coils to corrosion and high temperatures further augments their performance in high-pressure environments. These qualities, coupled with their reliability and capacity to withstand high pressure, render steel coils the preferred choice for industries seeking resilient and efficient equipment.

- Q: I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- I just use a regular spray on kitchen cleaner like 409. Then after I do that to prevent the streaks, just use baby oil. Put a tiny bit on a paper towel and wipe it over the doors. I learned this from online and from a pal that is in the navy. They can't have streaks on anything for navy inspections.

- Q: What type of metal is T10 tool steel?

- Carbon Tool Steel usually in the form of forged bar stock. Steel Grades for tool steel can be any of the following (depending on the application) T10/1.1645 SK3/SK4/W1A-91/2/ TC105/y10/1880/BW1B T10A/1.1545/y10A/1880 Standards are published by: DIN, JIS, ASTM, AISI, BS, SS, ISO, TOCT, GB Doug

- Q: What are the different types of steel coil surface treatments for outdoor applications?

- There are several different types of steel coil surface treatments that are commonly used for outdoor applications. These treatments are applied to the steel to enhance its durability, corrosion resistance, and appearance. Some of the most commonly used surface treatments for outdoor applications include: 1. Galvanized: Galvanization is a process where a layer of zinc is applied to the steel surface. This treatment provides excellent corrosion resistance, making it ideal for outdoor applications. Galvanized steel coils have a shiny, silver appearance. 2. Galvalume: Galvalume is a combination of aluminum and zinc, which is applied to the steel surface. This treatment provides superior corrosion resistance compared to galvanized steel. Galvalume steel coils have a duller, matte finish. 3. Painted: Steel coils can be painted with a variety of coatings to enhance their appearance and protect against corrosion. The paint can be applied in a single or multiple layers, depending on the desired level of protection. Painted steel coils are available in a wide range of colors and finishes. 4. Powder Coated: Powder coating is a type of paint coating that is applied as a powder and then cured under heat. This treatment creates a durable and long-lasting finish. Powder coated steel coils are resistant to chipping, scratching, and fading, making them suitable for outdoor applications. 5. Organic Coated: Organic coatings, such as PVC or PVDF, are applied to steel coils to provide additional protection against corrosion and weathering. These coatings are typically used in architectural applications where aesthetics and durability are important. These different types of steel coil surface treatments offer various levels of protection and aesthetic options for outdoor applications. The choice of treatment depends on factors such as the intended use, environmental conditions, and desired appearance.

- Q: How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are rolled and shaped into various structural components like beams, girders, and plates. These coils provide the necessary strength, durability, and flexibility required to support heavy loads and withstand the dynamic forces exerted on the bridge.

- Q: How are steel coils used in the production of household appliances?

- Steel coils are used in the production of household appliances as they serve as the primary material for manufacturing various components such as the outer body, frame, and internal structures. These coils are formed into different shapes and sizes, allowing for the creation of durable and robust appliances. The steel coils provide strength, stability, and resistance to wear and tear, ensuring the longevity and reliability of the appliances.

- Q: What are the cost considerations when purchasing steel coils?

- When purchasing steel coils, there are several cost considerations that need to be taken into account. Firstly, the price per unit of steel coil is a significant factor. The cost of steel coils can vary depending on various factors such as the type of steel, its grade, thickness, width, and length. Higher-grade steel coils tend to be more expensive than lower-grade ones, and thicker or wider coils can also come at a higher cost. Another cost consideration is the quantity of steel coils needed. Purchasing larger quantities of steel coils often comes with volume discounts, so it is important to determine the required quantity and assess whether it is more cost-effective to buy in bulk or in smaller batches based on the demand and storage capacity. Transportation costs should also be considered when purchasing steel coils. The weight and size of the coils can impact the shipping costs, especially if they need to be transported over long distances. Additionally, the distance between the supplier and the buyer can affect freight charges, so it is crucial to evaluate different shipping options and choose the most cost-effective method. Furthermore, it is essential to take into account any additional costs associated with processing or customizing the steel coils. For instance, if the coils need to be cut, leveled, or coated, these additional services can add to the overall cost. It is important to obtain quotes from different suppliers and compare the prices for these value-added services. Lastly, it is crucial to consider the overall quality and reliability of the steel coils. While cheaper options may initially seem more cost-effective, they could end up costing more in the long run if they do not meet the required standards or have a shorter lifespan. It is advisable to choose reputable suppliers with a track record of delivering high-quality products to ensure that the investment in steel coils is worthwhile. In conclusion, the cost considerations when purchasing steel coils include the price per unit, quantity discounts, transportation costs, additional processing services, and the overall quality and reliability of the coils. Evaluating these factors thoroughly will help make an informed decision that balances cost-effectiveness with the desired quality and specifications of the steel coils.

Send your message to us

Prepainted gavanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords