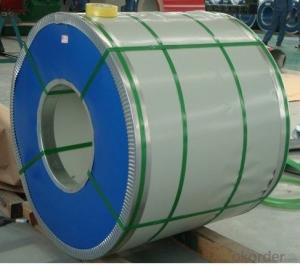

0.12mm-1.3mm Thickness Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Surface Treatment:Galvanized

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, JIS, AISI, DIN

Application:Container Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Q235B

Thickness:0.12mm-3.0mm

Coil Weight:3-8 Tons

Gloss:65%-80%

Export Markets:Global

ID:508mm

Zinc Coating:50g-250g/Psm

Feedback:Within 24 Hours

Additional Info.

Packing:Export Standard Package or as Request

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin:China

HS Code:7210701000

Production Capacity:150, 000tons/Year

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 25 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who answer. i'm leaning towards white-2 steel for my first sashimi knife, started training on the sushi bar and need a new tool!

- This Site Might Help You. RE: what is the difference between white steel and blue steel in reference to sushi knives? looking to buy a sashimi knife. what is the difference between white steel (1and2) and blue steel (1and2) in terms on characteristics. what gets sharper? what holds edge longer? basically any info on the pros and cons of each steel would be SO GREATLY APPRECIATED! thanks in advance to all who...

- Q: what are the properties that can strengthen the steel to withstand earhquake?

- okorder can give you helps.

- Q: What are the different grades of steel used in coil manufacturing?

- There are various grades of steel used in coil manufacturing, including low carbon steel, medium carbon steel, high carbon steel, stainless steel, and alloy steel. These grades differ in their composition, strength, and corrosion resistance, allowing manufacturers to choose the most suitable grade for specific applications and requirements.

- Q: I am reading the book The Cure For All Advanced Cancers by Hulda Regehr Clark.She writes for example: cancer can be caused by exposure to heavy metals, like nickel and chromium from stainless steel cookware. Stainless steel cookware releases chromium and nickel, two of the most carcinogenic metals.Are there any studies done measuring how much nickel and cadmium can be released from the regular use of stainless steel cookware?Is this a commonly accepted opinion that use of stainless steel cookware is dangerous?If not stainless steel, what kind of cookware to use? I heard that non-stick cookware also releases some harmful chemicals.

- Hi, I think that Stainless Steel is one of the safest ways to cook food. Glassware is also safe, but you must be careful not to drop the stuff, it can break and leave small pieces on the floor. Yes non-stick cookware can harm small fast breathing animals like birds in your house if the cookware overheats, but by keeping water or moisture in the bottom of the pan, and not using supper high heat, you can avoid overheating a non-stick surface. This also includes not scraping the surface with the utensils. Aluminum cookware, especially cast aluminum is considered by many as more than average toxic to many. Test for alltimers is that they contain aluminum in their bodies, and many owned aluminum cookware too. To kill cancer, look to Dr. Otto Warburg, who did win a Noble Prize for discovering how to kill the cancer cells.

- Q: i need working shoes for women that have steel toe shoes? What store do they sell them in . i live in c.a.

- Do a search for local safety toe shoes. I have to have them for work also, and as a woman I can't just go to Walmarts. Unfortunately the store I go to is here in Atlanta, so not much help. But there are specialty stores for safety shoes. Brands I like are Hytest and Georgia Boots. Especially the Hytest instead of steel toes which are heavy the toes are kevlar.

- Q: given the buoyant economic growth of india, what you guys think about steel industry? what can be the major issues in this industry in the coming days

- NAFTA became a unfastened commerce contract it is fairly a lot a republican proper. unfastened markets are a sturdy element. each and every so often unfastened markets deliver approximately the shortcoming of jobs in one sector yet that would not advise unfastened commerce is undesirable. opposition like that ensures that capital is spent in it is best way. Proping up death industries isn't a sturdy concept. i know it is not a favored element to declare, even though it is the certainty. would desire to we've propped up the horse and carriage marketplace while autos got here alongside so as that horse handlers did not lose thier jobs? in all risk not. unfastened commerce is a sturdy element. That being mentioned, i don't think of that Obama will merely blanketly wipe out any coverage by means of fact it became a Bush coverage. he isn't that stupid. If it became a sturdy coverage that labored, i'm particular it will be retained.

- Q: What are the different methods of coil slitting for steel coils?

- There exists a variety of techniques for coil slitting steel coils, each serving a specific purpose and employed in various industries. Here are several commonly used methods: 1. The most widely employed technique for coil slitting is rotary shear slitting. It entails the utilization of rotating knives to divide the steel coil into smaller strips. Renowned for its speed and precision, rotary shear slitting is ideal for large-scale production. 2. Loop slitting involves feeding the steel coil through a loop control system that maintains constant tension. Subsequently, a rotating knife is used to cut the coil into strips. Loop slitting is often utilized for thinner gauge materials due to its ability to produce clean, burr-free edges. 3. Oscillating shear slitting employs oscillating knives to cut the steel coil. These knives move back and forth rapidly, creating a shearing effect that facilitates cutting through the coil. This technique is commonly used for thicker gauge materials and can handle higher tensile strengths. 4. Crush cut slitting involves pressing a circular blade against the steel coil to cut it. The blade crushes the material, resulting in a cut. This method is frequently used for softer materials or when edge quality is not of utmost importance. 5. Slit edge rolling is a technique that involves rolling the edges of the steel coil after it has been slit. This process smooths out the edges and enhances the appearance of the strips. Slit edge rolling is often employed in applications that require a high-quality finish. 6. Laser slitting is a relatively new method that utilizes a laser beam to cut through the steel coil. This technique offers precision and can handle a wide range of thicknesses. Laser slitting is commonly used in high-precision applications where edge quality is crucial. These represent just a few of the various coil slitting methods for steel coils. The selection of a method depends on factors such as material thickness and tensile strength, desired edge quality, and the intended application of the slit strips.

- Q: I have samurai sword that is a replica of the kill bill sword. It says on the blade stainless steel, what can i use to shine and protect blade. It had and still does a wax.like coating on the blade sine i received it. Thx for ur help

- i like how you asked this in the Card Games section.

- Q: How are steel coils used in the automotive stamping process?

- Steel coils are essential for the automotive stamping process, serving as a crucial element. These coils are large rolls of steel, which are unwound and fed into stamping machines. They are typically made of high-quality steel and come in different thicknesses and widths to meet specific requirements for automotive parts. In the stamping process, the steel coils pass through a series of dies and presses that shape and form the metal into desired automotive components. To ensure a smooth and consistent feed into the stamping machine, the coils are unwound and straightened to remove any bends or twists. The stamping machine applies hydraulic or mechanical force to press the steel coil against a specially designed mold called a die. The die, often made of hardened steel, can withstand the pressure and provide accurate and repeatable results. At high speed, the steel coil is fed into the stamping machine, and as it passes through the die, the metal takes shape as various automotive parts such as body panels, doors, hoods, fenders, and structural components. The stamping process offers high precision and consistency, meeting required specifications and tolerances. After forming, the metal may undergo additional processes like trimming, piercing, or bending to achieve the final shape. These processes can be carried out in subsequent stamping stations or by using progressive dies that combine multiple operations into a single pass. Overall, steel coils are vital in the automotive stamping process, providing the necessary raw material to produce various components. The use of steel ensures strength, durability, and safety of automotive parts while maintaining cost-effectiveness and mass production capabilities.

- Q: A 100 kg solid steel ball with a radius of 5 m is being spun on ice with an angular velocity of 5 rev/s pointed into the ice (clockwise rotation when viewed from above).A student shoots a 10 kg marble at the steel ball. The marble hits the ball along its side as shown with an initial velocity of 5 m/s to the left. If, right after the collision, the final velocity of the marble is 2.5 m/s to the left, what is the angular velocity of the steel ball after the collision?

- You need to do conservation of angular momentum about the steel ball's axis. Angular momentum = I.ω The steel ball's initial ω = 5 rev/s = 5*2pi rad/s = 31.4 rad/s The steel ball's moment of inertia I = (2/5)*m*r^2 = 40*25 kg.m^2 = 1000 kg.m^2 The marble's initial ω = v / r where r is the perpendicular distance from the steel ball's axis You need to look at the diagram for this. The marble's I about the steel ball's axis is I = m*r^2 where r is the same as above. (marble is treated as a point mass). Then work out the total initial ang. momentum = final ang. momentum and solve for ω...

Send your message to us

0.12mm-1.3mm Thickness Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords