Prepainted Galvanized Steel in coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

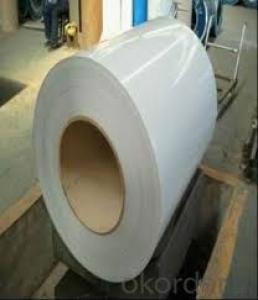

Prepainted Galvanized Steel

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: HBSTEEL

Specifications OfPrepainted Galvanized Steel

Thickness 0.20-1.2mm (BMT) Width 600-1250mm |

Zinc Coating 100-275g/m2 |

Color According to RAL color fan or as per request |

Internal Diameter 508mm or 610mm |

Coil Weight 3-6MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Applications OfPrepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

- Q: How are steel coils processed for slitting or edge trimming?

- Steel coils are processed for slitting or edge trimming by feeding them into a machine called a slitter. The slitter cuts the coils into narrower strips, which are then rewound onto separate spools. Edge trimming is done to remove any irregularities or imperfections from the edges of the strips, ensuring a smooth and uniform finish.

- Q: I was reading about the Colt 38 Super Custom and it said it's optional between a carbon steel frame or a stainless steel frame. What is the difference? There is also a choice between aluminium or stainless steel hammers and triggers can you also tell me the difference between them please?

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

- Q: How are steel coils used in the production of steel knobs?

- Steel coils are used in the production of steel knobs by being uncoiled and fed into a stamping press, where the steel is formed into the desired knob shape. This process allows for efficient mass production of steel knobs with consistent quality and strength.

- Q: Can steel coils be coated with color-changing materials?

- Yes, steel coils can be coated with color-changing materials.

- Q: What is the accuracy of steel tape inspection?

- The project is through the detection of steel tape, steel tape each batch have the error him different, so do projects each into a batch of steel tape has to go through the inspection department, let this batch of steel tape has reached the same error range. All the measuring tools in this project are unified into these steel tape measures, so that the measurement error is guaranteed.

- Q: I wanted to get a cheapo ring and I found one I like, but it's stainless steel. Is that bad? Will it get dull and tarnished fast?

- Stainless steel will never tarnish so you don't have to worry about it. It's a better choice than silver, for silver,you'll have to clean it with either a cleaner product or toothpaste. Oh yeah, and stainless steel has that cool and modern look.

- Q: What dangers were there for the steel workers in Pittsburgh under Carnegie?

- Same as other steel plants, getting crushed by falling steel, getting burned by hot metal etc

- Q: How are steel coils used in the production of construction equipment?

- Steel coils are used in the production of construction equipment as they provide a reliable and cost-effective material for manufacturing various components. These coils are often processed and shaped into specific parts, such as frames, chassis, and heavy-duty structures, which make up the foundation and framework of construction equipment. The high strength and durability of steel coils ensure that the equipment can withstand heavy loads, extreme conditions, and repetitive use, making them essential in the construction industry.

- Q: hello, I am trying to figure out what wok to get and came across a website that offers many woks out of different materials. what is the best, or considered original (traditional)? I have a couple of cast iron pots and pans - too heavy, so I am assuming it will take some time for a cast iron wok to heat up. what about carbon steel and stainless steel? Thanks

- Best Wok To Buy

- Q: How are steel coils inspected for weldability?

- Steel coils are inspected for weldability using various methods, such as visual examination, non-destructive testing (NDT) techniques like ultrasonic testing or magnetic particle inspection, and chemical analysis. These inspections help identify any surface defects, internal discontinuities, or impurities that may affect the weldability of the steel coils.

Send your message to us

Prepainted Galvanized Steel in coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords