Prepainted Galvanized Steel Coils Good Quality-CGC340

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted Galvanized Steel Coils Good Quality-CGC340

1. Structure of Prepainted Galvanized steel Coil :

•Prepainted galvanized steel qualified with excellent decorative ,formability ,corrosion resistance ,coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material for manufacturing board.

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

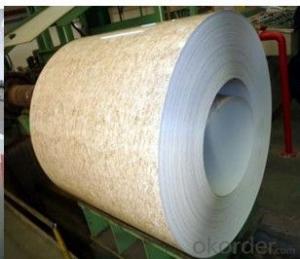

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard: ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.18mm~1.2mm,

Width: 600-1250mm

Coil weight:3-12 MT

5.FAQ of Prepainted Galvanized steel Coil

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: What is the maximum width of a steel coil?

- The maximum width of a steel coil can vary depending on the manufacturing process and the specific requirements of the industry. However, in general, steel coils can have a maximum width of around 2,200 millimeters (86.6 inches).

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes include scratches, pits, roll marks, stains, and unevenness. These defects can be caused by various factors such as improper handling, processing issues, or equipment malfunction. These surface defects affect the aesthetics and quality of the steel coil, making it unsuitable for certain applications or requiring additional processing to rectify the defects.

- Q: Basically when i'm older, my dream Job would be, to be to start a steel mill, I've always loved the idea of working in Business and investing in things has always been a hobby of mine. i play games where u invest and make money. all i need is some facts about starting a steel mill?What requirements i need,- How time consuming is it,- How easy is it,- How to get started,- The Perks,- The downsides..how much would it cost to start one, like land, place, iron etc, to get started? also i would need a bank loan, how much money will the bank give me ? 80%??

- Typically, steel mills are worth $20 million to $200 million and are owned by large corporations. Your best bet to own one would be to take over a corporation that already has one. That way you have all the supply lines, customers, experts and other workers already there, too. Stick with investing in going concerns, so you don't need to be an expert in each business to build it up. Get them ready made, learn the details from the people already doing it, then work out ways to improve it. Do not get tempted to borrow even 10c from the scammers who have answered your question. Start saving your real money, reading the financial news, and making small real investments in real stocks.

- Q: It seems that steel would be stonger and more stable than wood, fire resistant, and better for the environment, so why are most homes wood-framed rather than steel-framed?

- Because it's always been done that way. Never underestimate inertia when asking why new materials/techniques are not adopted. Besides, the cost does not give steel a clear advantage. You can drive a nail anywhere into a stud. With steel, you have to drill your holes precisely.

- Q: an 18k steel and gold, screw style bracelet how much would it be worth?

- Steel does not come in an 18k version and is worth only about $1.50/pound. 18k gold (.750 or 75% pure) is currently worth about $40.20/gram, based on the spot price of gold of $1,667/ounce at this moment.

- Q: How are steel coils used in the production of medical equipment?

- Steel coils are an essential component in the production of medical equipment as they are used to manufacture various parts and components such as surgical instruments, implants, and medical machinery. The high strength and durability of steel make it ideal for creating precise and long-lasting medical devices, ensuring the safety and reliability of the equipment used in the healthcare industry.

- Q: would you consider steel a flexible substance...i am debating this with my coworkers.Thanks,

- Steel is a flexible material. It can be deformed and return to it's original shape up while the stress applied is still in the elastic range. How flexible depends on size, shape, and alloy. Some alloys are more flexible than others and a lot of this is controlled by carbon content.

- Q: What is the difference between hot rolled and cold rolled steel coils?

- The main difference between hot rolled and cold rolled steel coils lies in the manufacturing process. Hot rolled steel coils are produced by heating the steel to high temperatures and then rolling it while it is still hot. This process results in a rougher surface and less precise dimensions, but it makes the steel more malleable and easier to shape. On the other hand, cold rolled steel coils are manufactured by cooling the hot rolled coils and passing them through a series of rollers at room temperature. This process produces a smoother surface and tighter tolerances, making it suitable for applications that require precise dimensions and a higher quality finish.

- Q: What are the different methods of edge wave correction for steel coils?

- There are several methods of edge wave correction for steel coils. One common method is using edge trimmers, which cut off the uneven edges of the coil to create a straighter edge. Another method is through tension leveling, where the coil is stretched to remove the wave-like deformities. Additionally, some manufacturers use roller leveling, where the coil passes through a series of rollers that press and flatten the edges. Lastly, laser technology can be employed to accurately measure and correct any edge wave deformities.

- Q: Apparently, this has to do something with electrochemical cells.

- Steel wood? I don't think there is such a thing?

Send your message to us

Prepainted Galvanized Steel Coils Good Quality-CGC340

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords