Prepainted Galvanized Steel Coil/PPGI ASTM A653 High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Prepainted Galvanized Steel Coil/PPGI ASTM A653:

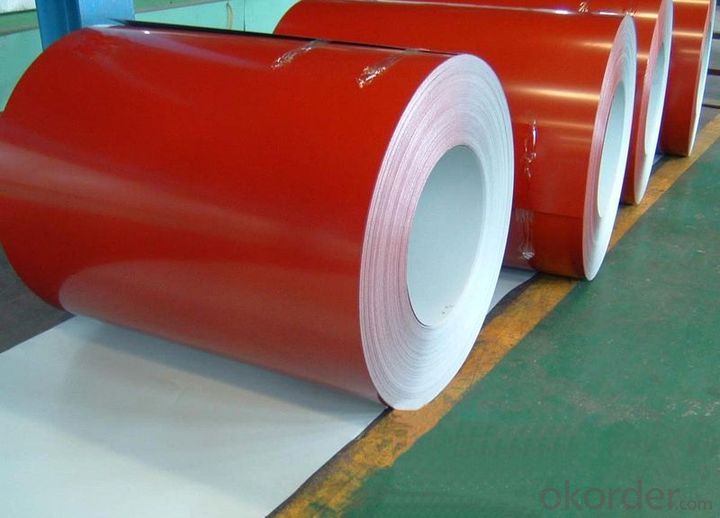

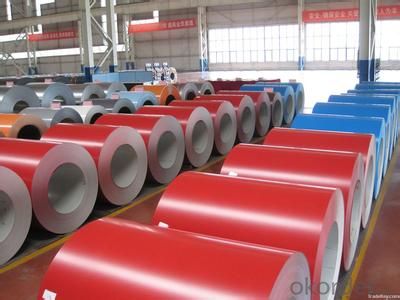

PPGI is the material which uses galvanized steel as the basic substrate metal. PPGI is prepainted galvanized steel, also known as precoated steel, coil coated steel, color coated steel etc.A galvanized steel sheet in coil form is cleaned, pretreated, applied with various layers of organic coatings which can be paints, vinyl dispersions, or laminates.These coatings are applied in a continuous process known as Coil Coating.The steel thus produced in this process is a prepainted, prefinished ready to use material.

2.Usage of Prepainted Galvanized Steel Coil/PPGI ASTM A653:

Outdoor: roof, roof structure, surface sheet of balcony, frame of window, door, garage doors, roller shutter door, booth, Persian blinds, cabana, refrigerated wagon and so on.

Indoor: door, isolators, frame of door, light steel structure of house, sliding door, folding screen, ceiling, internal decoration of toilet and elevator.

3.Prepainted Galvanized Steel Coil/PPGI ASTM A653 Images:

4.Prepainted Galvanized Steel Coil/PPGI ASTM A653 Specification:

Commodity | Prepainted Galvanized Steel Coil/Sheet | ||||

Standard | Q/BQB440 JISG3312 EN10327 | ||||

Grade | TDC51D/TDC52D/TDC53D/TS280GD/TS350GD/TS550GD/TSECC/TSECD/TSECE/CGCC/CGCC1/CGC400/ | ||||

CGC440/ CGC570/DX51D+Z/DX52D+Z/DX53D+Z/S280GD+Z/S350GD+Z/S550GD+Z/SECC/SECD/SECE | |||||

Thicknees | 0.14-0.8 mm | Width | 600-1250mm | ||

Zinc Coating | Z40-Z275g/m2 | Coil Weight(Min or Max) | 3-8 tons | ||

Coil Inner Diameter | 508mm | 610mm | Coil Outer Diameter(Max) | ||

Color | Ral color | As Customers' requirement | |||

Surface Finish | Normal Coated | Embossed | Printed | ||

Category Of Finish Coating | High-durability Polyester | Silicon Modified Polyesters | |||

Polyvinylidene Fluoride | Polyester | ||||

Anti-static | Easy-Cleaning | ||||

Coating Type | Top Surface | Bottom Surface | |||

Double Coated | Double Coated | ||||

Double Coated | Single Coated | ||||

Coating Thickness | Top Surface: | Back Surface: | |||

Coating Structure | Primer | Finish Coating | |||

Epoxy Primer | Polyester | ||||

Polyester Primer | Silicon Modified Polyesters | ||||

Water-soluble Acrylic Acid Primer | High-durability Polyester | ||||

Polyurethane Primer | Polyvinylidene Fluoride | ||||

Method of Test | <1>Acid/Alkaline-Resistance Test | <2>Test of Resistance to Neutral Mist | |||

<3>Air Exposure Test | |||||

Futher Process | Cut coil into Sheet | Corrugated Roofing Sheet | |||

5.PACKING:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: i have purchased a high dollar Martin guitar and i was wondering if there are many people out there that have used steel string acoustics for classical and flamenco guitar playing.otherwise i will need a nylon stringeror.. uld i put nylon strings on an old yamaha steel string guitar that i have?

- Guitars built for either nylon or steel strings are constructed differently. You will have problems putting nylon strings on a steel stringed guitar and visa verse. I say NEITHER is a good idea. If I were in your shoes, I would walk on line or to a guitar store and purchase a nylon stringed guitar. That's what I did years ago and now I am hooked. I got a second hand Takamine A/E that work just fine for a couple hundred and then just a yr or so ago I got a brand new one, an EC132C and I just LOVE it. As my skills improve I plan on upgrading to a custom built acoustic only with a cutaway. I like cutaways but not the electronics. I never plug into my amp hardly at all. Yamaha makes nylon guitars too VERY cheap and real good tonal quality, I was VERY impressed with one that I played. I upgraded my tuners on my new Takamine to Schaller 16:1 and put the old Takamine tuners on that Yamaha and it's a really nice little guitar to kick around on when I am at that person's place.

- Q: What are the common coil surface finish standards?

- Some common coil surface finish standards include mill finish, brushed finish, polished finish, and coated finish.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several different types of steel coil surface treatments that are used to enhance corrosion resistance. These treatments are applied to the surface of the steel coil to create a protective layer that prevents corrosion and extends the lifespan of the steel. Some of the common types of surface treatments for corrosion resistance include: 1. Galvanizing: This is one of the most popular and effective methods for protecting steel against corrosion. In this process, a layer of zinc is applied to the surface of the steel coil. The zinc acts as a sacrificial anode, corroding before the steel does, thus protecting it from rust and corrosion. 2. Chromate conversion coating: This treatment involves applying a chromate-based solution to the surface of the steel coil. The chromate forms a thin film on the steel, providing a protective barrier against corrosion. It also enhances the adhesion of paint or other coatings that may be applied later. 3. Phosphating: Phosphating is a process where a phosphate coating is applied to the steel coil. This coating provides excellent corrosion resistance by forming a chemical bond with the steel surface. It also improves the adhesion of subsequent coatings or paints. 4. Organic coatings: These coatings, such as paint or epoxy, are applied to the steel coil to create a barrier between the steel and the surrounding environment. They provide both corrosion resistance and aesthetic appeal. The choice of organic coating depends on the specific application and the desired level of corrosion protection. 5. Zinc-rich paint: Similar to galvanizing, zinc-rich paint contains a high concentration of zinc particles. When applied to the steel coil, the zinc particles provide sacrificial protection, preventing corrosion. This coating is often used in harsh environments or for steel coils that will be exposed to frequent moisture or saltwater. It is important to note that the choice of surface treatment depends on various factors such as the application, environment, budget, and required level of corrosion resistance. Consulting with a steel coil manufacturer or corrosion specialist is recommended to determine the most suitable treatment for a specific situation.

- Q: What would be a better knife one with damascus steel or one without? Why is damascus steel so special other than the look? And why do some people say high carbon steel is better than regular? mainly though I want to know about the damascus. Thanks, max points to best answer.

- This Site Might Help You. RE: Is a knife with damascus steel better than one with regular steel? or what about high carbon? What would be a better knife one with damascus steel or one without? Why is damascus steel so special other than the look? And why do some people say high carbon steel is better than regular? mainly though I want to know about the damascus. Thanks, max points to best answer.

- Q: im playing fallout 3 on ps3 and im at project purity. i keep dying and i heard about broken steel how or what is that plz help me out thnx.

- P.G.A/A. (Professional Gamer Advice/Answer) First off, what you need to know is Broken Steel is an expansion pack (to a certain extent). What you need to do is first download the content to the device that holds your Fallout 3 save files, be it PC or 360, and then you must simply complete Project Purity by choking to death... Or, if you have already done this and saved, then simply load up your game. You will know it's beginning when the old coot that leads the Brotherhood of Steel tells you that they have brought you Back from the dead. From there, you go on all sorts of wacky and explosion-filled adventures. There is even another segment with everyone's favorite patriotic technological warfare robot, Liberty Prime! And oh MAN is that part fun. As well, there are tons of new weapons, armors, and even the ability to (for a limited time) tame death-claws! But DO be careful, because they explode quite easily...there is also the Outcast Armor, which in my opinion is the most bad-*** because it is black armor with a red trim rather than a silver armor with a bluish-silver trim.

- Q: What are the different types of steel alloys used in coil production?

- There are several types of steel alloys used in coil production, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. These alloys offer varying levels of strength, corrosion resistance, and formability, making them suitable for different applications in industries such as automotive, construction, and manufacturing.

- Q: i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- Surgical steel is fine, titanium is by far the most superior metal though. I've found that piercings done with titanium as opposed to surgical steel have healed a lot easier. But keep in mind that if you just got the piercing you've got quite some time before you'll be able to change it.

- Q: Climbing ropes used by mountaineers are usually made of nylon. Would steel cable of equal strength as the nylon be just as good? What advantages and disadvantages would it have compared to the nylon?

- steel is NOT as flexible and much slipperier if you fall the nylon stretches to slow the victim but a steel cable would stop short and kill you

- Q: What are the common defects in steel coil finishes?

- There are several common defects that can occur in steel coil finishes. These defects can impact the appearance and functionality of the steel and may need to be addressed before the coil can be used or sold. 1. Coil breaks: Coil breaks are a common defect where the steel strip breaks during winding or unwinding. This defect can result in a discontinuity in the surface of the coil and can lead to further damage if not addressed. 2. Edge wave: Edge wave refers to a distortion or waviness at the edges of the steel coil. This defect can occur during the rolling or cooling process and can affect the flatness and uniformity of the coil. 3. Corrosion: Corrosion can occur on the surface of steel coils if they are not properly protected or stored. This can lead to rust and degradation of the steel, impacting its strength and appearance. 4. Streaks and stains: Streaks and stains can occur on the surface of steel coils due to improper cleaning or contamination during the production process. These defects can affect the aesthetic appearance of the steel and may need to be addressed before the coil can be used. 5. Scratches and dents: Scratches and dents can occur on the surface of steel coils during handling, transportation, or storage. These defects can impact the flatness and surface quality of the steel and may require repairs or adjustments. 6. Coating defects: If the steel coil has a coating or paint applied to it, several defects can occur. These include blistering, peeling, or uneven application of the coating, which can affect the durability and appearance of the steel. It is important to note that these defects can vary in severity and may require different methods of repair or mitigation. Regular inspections and quality control measures can help identify and address these defects before they become more significant issues.

- Q: a steel abr sells for about 879 now...a mith just over 1kany suggestions on which-keyword WHICH steel item to make-which is the best-exp wise, and steel bar conservative wise.

- If members, cannonballs. If not, steel kites, I suppose. Steel Platebody only alchs for 1200, and requires 5 bars... But I stuck with steel, till 70 smithing... cheaper, and requires less coal to make....

Send your message to us

Prepainted Galvanized Steel Coil/PPGI ASTM A653 High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords