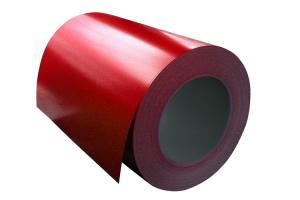

Prepainted Galvanized Steel Coil-Our Best Quality Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted Galvanized Steel Coil-Our Best Quality Products

Brief Introduction:

Prepainted Galvanized Steel usually refers to have substrate processed withsurface processed and coated then(roller coated )or bonded organicthin film and baked, and it is able to be processed to final prodevtion .

Prepainted Galvanized Steel qualified with excellentdecorative ,formability ,corrosion resistance ,coating adhesion ,can keep for along time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in constructionand save energy ,prevent pollution etc.Which is an ideal material;formanufacturing board.

Specification:

Thickness: 0.15-0.8mm

Width: 600-1250mm

Length: on request

Zinc coating: 30-275g/m2

Color: RAL series

Paint: PE, PVDF, PU

Application:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations,window frames, etc

2.Electrical appliances: computer shells, washing machines,refrigerators, dehumidifiers,video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools,agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks,conveying systems, oil tanks, etc.

Advantages:

1. High strength

2. Well rainproof performance

3. Good corrosion

4. Easy to install and remove

5. FAQ of Steel

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: I understand that damascus sword steel was made by folding the strip of steele double , reheating, hammering, folding again and so forth hundreds of times. Was this the same or very nearly the same techmique the japs used making the sword blades the samari swords?(forgive the misspelling)

- The samari swords are made by folding to make many many alternating layers of different steel compositions. Damascus swords were made differently. The steel was heated and forged (like samari swords) but it was not folded. The patterns produced are due to the micro macro-structure of the steel alloy and the way the steel is forged. Fake Damascus steel knives and gun barrels and other items have been made by pattern welding (forge cladding steels with different compositions together) and then folding and forging with some tricks. google damascus steel and you will find lots of info. hope this helps

- Q: Can steel coils be painted?

- Yes, steel coils can be painted. Painting steel coils not only enhances their aesthetic appearance but also provides a protective coating against corrosion and other environmental factors. The coils are typically pre-treated and primed before the application of paint to ensure proper adhesion and durability.

- Q: I've seen on TV that stainless steel laminate sheets can be purchased and and used to cover appliances to give it a faux stainless steel look. They mentioned it was important to not have any bubbles (of course) and to work slowly. It's easy to do on a dishwasher, but what about the fridge? The handles are in the way? Do you have to take the handles off? Can anyone find a tutorial for me?

- There okorder appliance paint 2. What you are referring to really is not laminate steel sheets, it's actually more along the lines of shelf liner paper looks like steel with sticky back film that you peel and stick. Place against product and begin to peel down slowly using squeegee or credit card to smooth out bubbles.Sheets can be purchased rangingin size on OKorder for $9.99 + dependent on size. Called stainless steel appliance film can buy a roll for $60.00 on OKorder (normally sells for $100.00) one roll will cover 3 average sized kitchen appliances. Hope this helps!

- Q: How are steel coils used in the production of metal containers?

- Steel coils are used in the production of metal containers by being processed and formed into sheets, which are then shaped and welded to create the body and lids of the containers. The strength and durability of steel make it an ideal material for these containers, providing protection for goods during transportation and storage.

- Q: What is the cost of steel coils?

- The cost of steel coils can vary depending on factors such as size, quality, and market conditions. It is best to contact a supplier or check current market prices to get an accurate cost.

- Q: How are steel coils used in the production of roofing materials?

- Steel coils are used in the production of roofing materials as they are rolled out and cut into specific lengths, forming the base material for roofing panels or shingles. These coils provide durability, strength, and resistance to weather conditions, ensuring long-lasting and reliable roofing solutions.

- Q: How are steel coils used in the manufacturing of storage cabinets?

- Steel coils are used in the manufacturing of storage cabinets as they provide the raw material for forming the cabinet's metal components. Coils are unrolled, cut, and shaped into the necessary panels, shelves, and doors, which are then assembled to create the cabinets. The strength and durability of steel make it an ideal material for these cabinets, ensuring they can safely store and organize various items.

- Q: I was watching a documentary on the samurai vs the European knight. It said that the when Japan was being invaded by the (cant remember) they needed a new weapon. The enemies armor made iron swords useless. While steel swords broke when in combat. So to combat this the Japanese made a hybrid sword. They used a special mold that made the swords back iron while the part that makes contact with the enemy was steel. Also the sword was curved so it increased its armor and cutting power. This revolutionary design made the the sword stronger. The iron back made it not break while the steel edge made it cut through the enemies armor. I want to know how iron is stronger than steel, and how steel can cut better than iron.

- Yes because metal alloys are comparatively more strong than pure metal.The worst thing is that iron gets rusted whereas steel does not.And the skyscrapers are made of steel buddy , iron is not used in them.

- Q: How are steel coils distributed globally?

- Steel coils are distributed globally through a well-established supply chain network. Manufacturers typically ship steel coils to various locations worldwide through ocean freight or rail transportation. These coils are then distributed to customers, including construction companies, automotive manufacturers, and other industries, through local distributors or directly from steel service centers. Additionally, international trade and partnerships play a significant role in the global distribution of steel coils, ensuring a steady supply to meet market demands.

- Q: What are the common methods of welding steel coils?

- Some common methods of welding steel coils include gas metal arc welding (GMAW), also known as MIG welding, and submerged arc welding (SAW). These methods offer efficient and reliable ways to join steel coils together, ensuring strong and durable welds.

Send your message to us

Prepainted Galvanized Steel Coil-Our Best Quality Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords