Prepainted Galvanized Steel Coil-EN 10169 S220GD+Z--High Strengh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted Galvanized Steel Coil-EN 10169 S220GD+Z--High Strengh

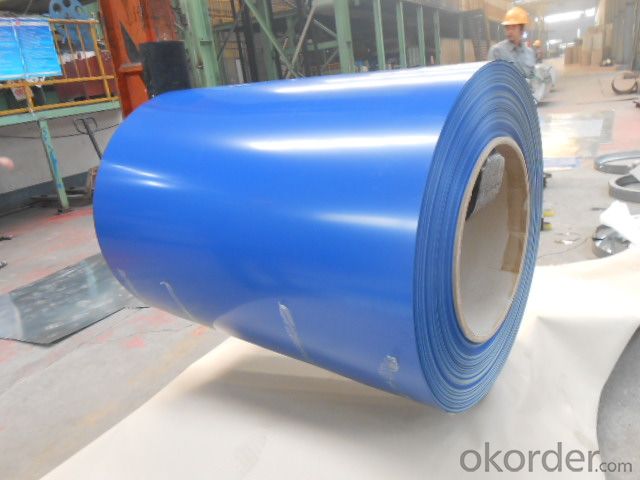

Description of Prepainted Galvanized Steel Coil-EN 10169 S220GD+Z

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final prodevtion .

Prepainted Galvanized Steel qualified with excellent decorative ,formability ,corrosion resistance ,coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc.Which is an ideal material;for manufacturing board.

Specification:

Thickness: 0.18-0.8mm

Width: 600-1250mm

Length: on request

Zinc coating: 30-275g/m2

Color: RAL series

Paint: PE, PVDF, PU

Images

Application:

1.Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations,window frames, etc

2.Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers,video recorders, water heaters, etc.

3. Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Main Features:

1. High strength

2. Well rainproof performance

3. Good corrosion

4. Easy to install and remove

FAQ

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of storage tanks?

- Steel coils are used in the manufacturing of storage tanks as they provide the necessary strength and durability required for storing various substances. These coils are formed into cylindrical shapes and welded together to create the tank's body. The steel coils are also coated with protective layers to prevent corrosion and ensure the longevity of the tank.

- Q: How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties using various non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help to assess the strength, hardness, and other mechanical properties of the steel coils without causing any damage to the material.

- Q: How are steel coils used in the production of food processing machinery?

- Steel coils are used in the production of food processing machinery as they serve as a key component for constructing the machine's framework and structure. The coils provide durability, strength, and resistance to the machinery, ensuring its reliability and longevity in food processing operations.

- Q: so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- It rather relies upon on what type of music you're enjoying, nylon string guitars have a mellow, softer tone than steel strings, the feel of the nylon strings (a minimum of to me) are reliable, in my opinion, i might ought to declare nylon is extra suitable, large for finger choosing and a effective tone. once you're searching for a guitar, you are able to flow out to a close-by guitar save, and attempt the two out for your self, in straight forward terms then will you comprehend for specific.

- Q: What are the different coil slitting line configurations used for steel coils?

- There are several different coil slitting line configurations that are used for steel coils, each with their own specific advantages and applications. These configurations include: 1. Simplex Slitting Line: This configuration consists of a single slitter head that cuts the coil into multiple smaller widths. It is suitable for lower production volumes and is often used for processing thinner gauge materials. 2. Loop Slitting Line: In this configuration, the steel coil is fed through a loop pit, which allows for continuous processing without stopping the line. It is commonly used for high-volume production and is ideal for thicker gauge materials. 3. Double Loop Slitting Line: Similar to the loop slitting line, this configuration includes two loop pits, which increases the line's efficiency and productivity. It is typically used for processing thicker gauge and wider width materials. 4. Tension Stand Slitting Line: This configuration includes a tension stand that applies constant tension to the material during the slitting process. It helps to maintain consistent slit widths and is often used for high-precision slitting applications. 5. Rotary Shear Slitting Line: In this configuration, a rotary shear cuts the steel coil into smaller widths. It is suitable for both thin and thick gauges and offers high-speed and accurate cutting. 6. Scrap Winder Slitting Line: This configuration includes a scrap winder that collects the excess material trimmed during the slitting process. It helps to improve efficiency and reduce waste. 7. Combination Slitting Line: This configuration combines multiple slitting processes into one line, allowing for different slitting methods and widths to be achieved within a single setup. It offers flexibility and versatility in processing various steel coil sizes and materials. These different coil slitting line configurations provide various options for manufacturers to choose from based on their specific production requirements and the properties of the steel coils being processed.

- Q: How are steel coils stored and transported?

- Steel coils are typically stored in warehouses or outdoor storage yards. They are usually stacked horizontally, one on top of the other, with wooden or steel supports placed between each coil to prevent damage. When it comes to transportation, steel coils are usually loaded onto flatbed trucks or shipping containers using cranes or forklifts. It is important to secure the coils properly during transportation to prevent any shifting or damage.

- Q: What are the common uses of coated steel coils?

- Coated steel coils are commonly used in various industries for applications such as automotive manufacturing, construction, and appliance production. These coils are utilized in the production of metal roofs, siding, garage doors, HVAC systems, and electrical appliances. The coating on the steel provides protection against corrosion, enhances durability, and improves aesthetics, making it an ideal choice for these applications.

- Q: I know the law regarding selling steel core ammo, but is it possible to buy a steel core bullet and load it yourself?

- I don't ever recall seeing reloading components listed as steel core but I guess they could be out there. Why on earth would you want to load steel core if regular projectiles are available?

- Q: What are the challenges in coil leveling for high-strength steel?

- One of the main challenges in coil leveling for high-strength steel is the material's inherent strength and hardness. High-strength steel is designed to have superior mechanical properties, which can make it difficult to manipulate and flatten during the leveling process. The high tensile strength and increased yield strength of the steel can cause it to resist deformation, leading to springback or permanent deformation issues. Additionally, the increased hardness of the steel can put more strain on the leveling equipment, potentially leading to wear and tear. Proper equipment selection, precise control of leveling parameters, and advanced process monitoring techniques are required to overcome these challenges and achieve accurate and consistent coil leveling results for high-strength steel.

- Q: How are steel coils used in the manufacturing of suspension systems?

- Steel coils are used in the manufacturing of suspension systems as they provide the necessary support and cushioning for vehicles. These coils, also known as coil springs, are placed between the vehicle's chassis and the wheels to absorb impact and ensure a smooth ride. The steel coils are designed to compress and expand under the weight and movement of the vehicle, effectively absorbing shocks, vibrations, and uneven road surfaces. This helps to improve stability, handling, and overall comfort for the driver and passengers.

Send your message to us

Prepainted Galvanized Steel Coil-EN 10169 S220GD+Z--High Strengh

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords