Prepainted Galvanized Steel Coil-China Best in Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

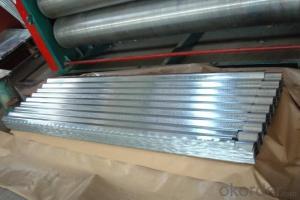

Prepainted Galvanized Steel Coil-China Best in Good Quality

Brief Introduction:

Prepainted Galvanized Steel usually refersto have substrate processed with surface processed and coated then(rollercoated )or bonded organic thin film and baked, and it is able to beprocessed to final prodevtion .

PrepaintedGalvanized Steel qualified with excellent decorative ,formability ,corrosionresistance ,coating adhesion ,can keep for a long time as well as maintainfresh color .For color coated steel sheet can obtain good economicbenefit by steel belt wood ,efficient in construction and save energy ,preventpollution etc.Which is an ideal material;for manufacturing board.

Specification:

Thickness:0.15-0.8mm

Width:600-1250mm

Length:on request

Zinccoating: 30-275g/m2

Color:RAL series

Paint:PE, PVDF, PU

Application:

1.Buildings and constructions:roofing, ceilings, gutters, venting lines, indoor decorations,windowframes, etc

2.Electrical appliances:computer shells, washing machines, refrigerators, dehumidifiers,videorecorders, water heaters, etc.

3. Agriculturalequipments: troughs, feeding tools, agricultural driers, irrigation channels,etc.

4. Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

Advantages:

1. High strength

2. Well rainproof performance

3. Good corrosion

4. Easy to install and remove

5. FAQ

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the manufacturing of household appliances?

- Steel coils are used in the manufacturing of household appliances as a raw material for forming various components such as panels, frames, and structures. The coils are typically cut, shaped, and welded to create the necessary parts used in appliances like refrigerators, stoves, and washing machines. The durability and strength of steel make it an ideal material for ensuring the longevity and performance of these appliances.

- Q: How are steel coils used in the production of storage racks?

- Steel coils are used in the production of storage racks as they serve as the primary raw material for manufacturing the rack components. These coils are typically cut and formed into various structural shapes, such as uprights, beams, and crossbars, which are then assembled to create the storage rack system. The strength and durability of steel make it an ideal material for supporting heavy loads, ensuring the stability and longevity of the storage racks.

- Q: I own a crappy steel string acoustic and a very nice electric guitar.I have saved up to buy a new acoustic but I cannot decide to just invest in a better steel string or explore around with a nylon string. From others experience, will I get my fill of satisfaction of playing on a nylon, or should I stick to a steel string?

- Nylon string guitars are mostly classical guitars ment for classical and flamenco music, both guitars, nylon and steel, sound really well. My dad has a steel acoustic and I have a nylon classical guitar by Cordova It just depends on what style of music you play. When your buying a new guitar, play as many guitars to try them out once you find what you which one you want, you'll know

- Q: What are the common coil transportation options?

- The common coil transportation options include trucking, rail transport, and sea freight.

- Q: How are steel coils used in the manufacturing of braking systems?

- Steel coils are used in the manufacturing of braking systems as they are commonly used to make brake pads and brake rotors. Steel coils are processed and shaped into the required forms to create these essential components, which play a crucial role in the braking system's functionality and performance.

- Q: So I'm looking for some decently priced black motorcycle boots that have steel toes (and any additional protection) and look good in jeans. Pretty simple. Any recommendations?

- You don't need steel toes in a motorcycle. The top of the foot isn't where the danger comes from when injured in a motorcycle accident. Where you need the most protection is in the ankle and heel. The ankle twists and the heel and calf bang on the ground. You need some protection at the toes, but that is from the road impacting the toes and grinding against the boots as you slide. Any boots made for motorcyclists will do. Stay away from steel toed work boots - they are designed for a job site, not a motorcycle crash.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using heavy-duty cranes and specialized equipment. When loading, the coils are lifted from the dockside or storage area using a crane with strong lifting capacity. They are carefully positioned onto the ship's deck, ensuring proper balance and securement to prevent any damage during transit. Unloading is done in a similar manner, with the crane carefully lifting the coils from the ship's deck and placing them onto the dock or designated storage area. Throughout the process, safety protocols are followed to ensure the smooth and efficient handling of these heavy and valuable cargo.

- Q: What are the common uses of coated steel coils?

- Common uses of coated steel coils include roofing, siding, automotive parts, appliances, and building materials. The coating on the steel helps to protect it from corrosion and enhances its durability, making it suitable for various applications in industries such as construction, manufacturing, and transportation.

- Q: How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they serve as a primary material for constructing various components such as turbines, generators, and transformers. The steel coils are shaped, cut, and welded to create sturdy structures that can withstand high temperatures and pressures, ensuring reliable and efficient power generation.

- Q: How are steel coils inspected for uniformity?

- To ensure uniformity, steel coils undergo a series of visual and mechanical tests. First, the coil's external appearance is carefully examined for any visible defects like dents, scratches, or rust. This is crucial to maintain the coil's integrity and prevent potential issues during further processing. Next, non-destructive testing techniques such as ultrasonic or magnetic particle inspection are used to measure the coil's thickness at various points. This helps identify any variations in thickness that could affect the overall quality and performance of the coil. Precise instruments are also employed to measure the coil's width and ensure it adheres to the required specifications. This is important for compatibility with downstream processes and applications. Furthermore, the weight of the coil is measured to verify if it falls within the specified range. Weighing scales or load cells are typically used for this purpose, ensuring consistent weight that meets the required standards. For internal inspection, steel coils may undergo eddy current testing, a non-destructive method that detects surface and near-surface defects. By utilizing electromagnetic induction, this technique can identify irregularities in the metal, such as cracks, voids, or inclusions. In summary, a comprehensive combination of visual inspections, thickness measurements, width checks, weight verification, and internal testing methods ensures thorough inspection for uniformity in steel coils. These rigorous processes guarantee the quality and reliability of the coils, enabling them to meet industry standards and customer requirements.

Send your message to us

Prepainted Galvanized Steel Coil-China Best in Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords