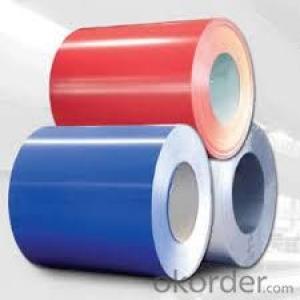

Prepainted Galvanized Rolled Steel coil Sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Prepainted Galvanized Steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion .

PrepaintedGalvanized Steel qualified with excellent decorative ,formability ,corrosionresistance ,coating adhesion ,can keep for a long time as well as maintainfresh color .For color coated steel sheet can obtain good economicbenefit by steel belt wood ,efficient in construction and save energy ,preventpollution etc.Which is an ideal material;for manufacturing board.

Applications:

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Packaging & Delivery:

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images:

- Q: A friends of mine says he has balls of steel and i told him i would melt em off with lava. He said it wouldnt work. i disagree

- Standard steel melts around 1400-1500 C. Erupting lava can be as hot as 1600 C. There are various types of steel with different melting points though, and the temperature of lava varies widely, so your question can't really be answered definitively. Some lava is definitely hot enough to melt steel though, so you are right and your friend is wrong. :)

- Q: How are steel coils used in the manufacturing of construction formwork?

- Steel coils are used in the manufacturing of construction formwork to create the framework and support structures needed for pouring concrete. The steel coils are typically shaped and cut into various sections to form the desired shape and size of the formwork. These coils provide strength, durability, and stability, ensuring that the formwork can withstand the weight and pressure of the concrete during the construction process.

- Q: How are steel coils used in the manufacturing of automotive frames?

- Steel coils are used in the manufacturing of automotive frames by being processed into flat sheets, which are then cut and formed into the desired shape and size to create the frame components. These components are then welded together to form the strong and durable structure of the automotive frame.

- Q: How are steel coils inspected for straightness?

- Steel coils are inspected for straightness through a variety of methods to ensure they meet the required quality standards. One common method is visual inspection, where trained inspectors visually examine the coil for any visible defects or deformations that may indicate a lack of straightness. They carefully observe the coil's edges, surface, and overall shape to identify any irregularities. Another method used is measuring the coil's straightness using precision instruments. This involves taking measurements at various points along the coil's length and comparing them against specified tolerances. Techniques such as laser measurements or straightness gauges are employed to accurately assess the deviation from the desired straightness. Furthermore, some coils undergo non-destructive testing, such as magnetic particle inspection or ultrasonic testing, to identify any internal defects or stresses that could affect the straightness. These tests can reveal hidden flaws that may not be evident through visual inspection alone. In addition, some manufacturers may employ automated inspection systems that utilize advanced technologies like computer vision or artificial intelligence. These systems can quickly scan the coil's surface and analyze it for any deviations from straightness, providing precise measurements and ensuring consistent quality. Overall, the inspection of steel coils for straightness involves a combination of visual inspection, precise measurements, non-destructive testing, and advanced technologies. These methods aim to identify any deviations from the required straightness, ensuring that only coils meeting the specified standards are used in various applications.

- Q: How are defects in steel coils repaired?

- Defects in steel coils can be repaired through several methods depending on the type and extent of the defect. One common approach is known as welding repair, which involves using specialized welding techniques to fix the defect. This method is typically used for minor defects such as cracks or small holes in the coil. The damaged area is cleaned, prepped, and then welded using appropriate welding rods or wires to ensure a strong and durable repair. For more severe defects, such as large holes or significant damage to the coil, a patching technique may be employed. This involves cutting out the damaged section and replacing it with a new piece of steel. The patch is usually welded to the intact areas of the coil, ensuring a secure and seamless repair. In some cases, defects can also be addressed through grinding or sanding techniques. This is often used for surface defects like scratches or blemishes that do not compromise the structural integrity of the coil. Grinding or sanding the affected area smooths out the defect, improving the appearance and preventing further damage. It is worth noting that the repair method chosen depends on factors such as the specific defect, the material of the coil, and the intended application of the steel. The repair process may also involve additional steps such as heat treatment or surface finishing to restore the coil to its original condition. Overall, repairing defects in steel coils requires the expertise of skilled technicians and specialized equipment. It is crucial to address these defects promptly to prevent further damage and ensure the coil's performance and longevity.

- Q: case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

- Q: y does 1095 steel on a katana weight about a pound less for the same amount than 1045? the 1095 is better right? but then why is 1045 steel more comenly used for practical use than 1095, even though i no its cheaper to use 1045 for tami mats. so is 1095 steel the better investment for buying and minor tami mat use?

- the grade of the sword is one aspect but there's more to it. the quality of the sword itself is a much more important factor a good quality 1045 grade blade can often be much better than a medium quality 1060 or 1095 blade. the quality of the work is much more important than the grade of the steel

- Q: I work at a tool store. I told my boss last week we needed more pruning shears so he did get more of all kinds. Thing is out of all of the shears he brought Two of different kinds say they are made out of Japanese steel. I have never heard of Japanese steel so now i ask you (the public) whats the difference between it and steel from the US or any other country? Those shears are worth more then the ones he gets from Mexico and China and even more than Black and Decker, Fiskars, etc but not more then Corona brand ones.

- I doubt japanese steel has any special quality in its own, but they might just be higher quality shears. For example, Chinese qualities are good depending on what they are, but are usually not professional made with the greatest equipment. Same for Mexico. The company that makes them might just put more effort into making sturdier and sharper shears and thus make them more expensive, but Corona might make them a bit better so they are priced less than Corona's.

- Q: How are steel coils used in the manufacturing of tools?

- Steel coils are often used in the manufacturing of tools as they provide a sturdy and durable material to create various components of the tools. The coils are shaped and cut into specific sizes and shapes to form the tool's body, handles, or blades. This allows for the production of high-quality tools that can withstand heavy use and provide the necessary strength and reliability required for different applications.

- Q: What brand steel tapes are of good quality?

- Durable durable depends on your personal use frequency, the high frequency nature is easy to wear, resulting in scale. If you like fuzzy units if buying tape need verification it is best to buy the Great Wall Seiko goods, because the time to measure the number of verification inspection of steel tape, basically qualified rate of the Great Wall Seiko steel tape can reach one hundred percent.

Send your message to us

Prepainted Galvanized Rolled Steel coil Sheet-CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords