Prepainted Galvanized rolled Steel Coil -Blue in CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

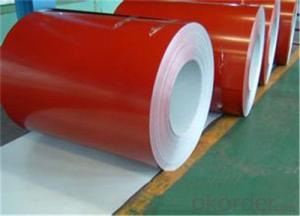

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images of Prepainted Galvanized Steel:

- Q: Which steels were origianally designed to be used to cut and shape metals and other materials?- alloy steel- high carbon steel- carbide steel- tool steelthanks

- Tool steels These were designed to be used as hardenable, dimensionally stable materials for cutting of metals. The alloying elements they contain (including tungsten, vanadium, niobium and molybdenum as well as chromium)are there to produce carbides (mainly) which are stable at dull-red heat. This cannot be achieved with high carbon steels, carbide steels or (normal) alloy steels which all lose their strength and hardness at metal cutting temperatures.

- Q: What are the advantages of using galvanized steel coils?

- There are several advantages to using galvanized steel coils. Firstly, galvanized steel is highly resistant to corrosion, which means it can withstand exposure to moisture and other harsh environmental conditions without rusting. This makes it a durable and long-lasting material for various applications. Secondly, galvanized steel coils have a protective zinc coating that acts as a barrier against damage and provides excellent structural strength. Additionally, galvanized steel coils are versatile and can be easily formed, welded, and painted, making them suitable for a wide range of industries and projects.

- Q: What are the different methods of annealing steel coils?

- The different methods of annealing steel coils include full annealing, process annealing, spheroidize annealing, and stress relief annealing.

- Q: Can steel coils be coated with zinc-aluminum alloy?

- Yes, steel coils can be coated with zinc-aluminum alloy, which is often referred to as galvalume or zincalume coating. This type of coating provides excellent corrosion resistance and durability to the steel coils, making them suitable for various applications in industries like construction, automotive, and appliances.

- Q: What are the common surface defects found in steel coils?

- Some common surface defects found in steel coils include rust, scratches, dents, pits, and mill scale.

- Q: How are steel coils annealed to improve their properties?

- Steel coils are annealed to improve their properties through a process called annealing, which involves heating the coils to a specific temperature and then slowly cooling them. This process helps to relieve internal stresses, enhance ductility and toughness, and refine the grain structure of the steel, resulting in improved mechanical properties such as increased strength and reduced brittleness.

- Q: Does SA use its own iron ore to produce steel for construction or do we rely on imports?

- There is a ludicrous mixture of the two at present. We export a large percentage of our steel to China predominantly but also to other regions then import what ever the shortfall is on the local market, often at inflated prices. The company I work for obtains all its steel from only one supplier, who we have shares in, and under the counter cash incentives are the order of the day, I keep myself above water by refusing the cash and sign no documents relating to those dealings, I'm not prepared to go to prison for a cash bonus.

- Q: What are the different methods of blanking steel coils?

- There are several methods used for blanking steel coils, which are: 1. Shearing: This method involves cutting the steel coil into the desired size and shape using a shear or a set of shears. Shearing is a common method used for blanking steel coils as it is a fast and cost-effective process. It is suitable for cutting thin to medium-thickness steel coils. 2. Laser cutting: Laser cutting is a precise and efficient method that uses a high-powered laser beam to cut through the steel coil. It is suitable for cutting complex shapes and thick steel coils. Laser cutting provides clean and accurate cuts, making it a preferred method for high-quality blanking. 3. Waterjet cutting: Waterjet cutting uses a high-pressure stream of water mixed with an abrasive material to cut through the steel coil. This method is versatile and can cut through various materials, including steel, without generating heat. Waterjet cutting is suitable for cutting thick steel coils and is often used for intricate shapes and designs. 4. Stamping: Stamping is a method that involves pressing a die into the steel coil to cut out the desired shape. This process is commonly used for high-volume production as it can rapidly cut multiple pieces at once. Stamping is suitable for cutting simple shapes and is often combined with other processes like shearing or laser cutting for more complex shapes. 5. Plasma cutting: Plasma cutting uses a high-velocity jet of ionized gas to cut through the steel coil. It is suitable for cutting thick steel coils and can handle a wide range of materials. Plasma cutting is known for its speed and versatility, making it a popular method for blanking steel coils. These methods of blanking steel coils provide different benefits depending on the requirements of the project, such as speed, precision, complexity of shapes, and material thickness. The choice of method depends on factors like cost, production volume, desired quality, and turnaround time.

- Q: How do steel coils contribute to sustainability in manufacturing?

- Steel coils contribute to sustainability in manufacturing in several ways: 1. Recyclability: Steel is one of the most recycled materials in the world, with a recycling rate of over 90%. Steel coils are made from recycled steel and can be recycled again at the end of their life cycle. This reduces the need for extracting raw materials, conserves natural resources, and reduces energy consumption and greenhouse gas emissions associated with steel production. 2. Durability: Steel is known for its strength and durability. Steel coils are designed to withstand heavy loads, extreme temperatures, and harsh environmental conditions. This means that products made from steel coils, such as automotive parts, construction materials, and appliances, have a longer lifespan, reducing the need for frequent replacements and minimizing waste. 3. Energy efficiency: Steel coils are used in various manufacturing processes, such as stamping, forming, and welding. These processes require less energy when working with steel coils compared to other materials. Steel's high strength-to-weight ratio allows for the production of lightweight yet strong components, reducing energy consumption during transportation and improving fuel efficiency in vehicles. 4. Reduced emissions: Steel coils contribute to sustainability by helping manufacturers reduce their emissions. Steel is a low-carbon material, and its production emits fewer greenhouse gases compared to other materials like aluminum or plastics. By using steel coils, manufacturers can reduce their carbon footprint and contribute to climate change mitigation efforts. 5. Circular economy: Steel coils are a key component in the circular economy, which aims to minimize waste and maximize resource efficiency. Steel coils can be easily recycled and reused, ensuring that they remain in the production cycle for a longer time. This reduces the need for virgin materials and promotes a more sustainable and circular approach to manufacturing. In conclusion, steel coils contribute to sustainability in manufacturing by being recyclable, durable, energy-efficient, emission-reducing, and promoting a circular economy. By choosing steel as a material and utilizing steel coils, manufacturers can make significant strides towards reducing their environmental impact and fostering a more sustainable manufacturing industry.

- Q: How do steel coils compare to other materials?

- Steel coils have several advantages over other materials. Firstly, steel is known for its high strength and durability. This makes steel coils highly resistant to wear and tear, making them suitable for a wide range of applications. Additionally, steel coils have excellent heat resistance, making them ideal for use in high-temperature environments. Furthermore, steel coils have superior corrosion resistance compared to many other materials. This is especially important in industries such as construction and automotive, where exposure to moisture and chemicals is common. Steel coils can withstand these harsh conditions, ensuring long-lasting performance and reliability. Another advantage of steel coils is their versatility. Steel can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. This makes steel coils suitable for a wide range of applications, including manufacturing, construction, transportation, and energy industries. Moreover, steel coils offer good value for money. Despite their numerous benefits, steel coils are generally more affordable compared to other materials such as aluminum or copper. This makes steel coils a cost-effective choice for businesses and industries looking for high-quality and reliable materials. In summary, steel coils have several advantages over other materials. They offer high strength, durability, and heat resistance, along with superior corrosion resistance. Steel coils are also versatile and can be easily customized to suit different applications. Additionally, they provide good value for money. Overall, steel coils are a reliable and efficient choice for various industries and applications.

Send your message to us

Prepainted Galvanized rolled Steel Coil -Blue in CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords