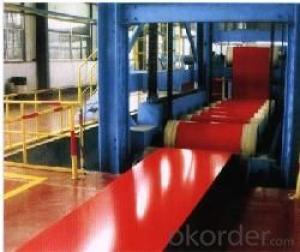

Prepainted galvalume steel coils RAL Color No.

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

colour coated steel

painting colour steel , zinc coated steel , lead coated steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.5mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: |

building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

price: | favorable price |

|

Packaging & Delivery

Packaging Detail: | standard export packing or customized |

Delivery Detail: | 15 days after prepayment |

Specifications:

galvanized steel coil:

1.Thickness:0.17mm-1.5mm

2.Zinc coated:40g-275g/2

3.Standard:dx51d+z,sgcc

We manufacture Galvanized Steel Coils,Pre-painted Galvanized Steel Coils , etc

Prepainted steel coil features:

1. Zinc coating :40-120g(as reauired)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment:RAL color

Galvanized steel coil features:

1. Zinc coating :40-275g( as required)

2. thickness:0.17-1.2mm

3. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

4. coil id:508m610mm

5. coil weight: 3-12(as required)

6. surface treatment: cremated, oiled, skin passed

7. Spangle: regular,small, zero

8.Application: With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Product name | steel coil,galvanized steel,galvanized steel coil |

Material | DX51D, SGCC, SPCC, CGCC, DX51D |

Normal thickness | 0.17-1.2mm |

Normal width | 900mm,914mm, 1000mm, 1200mm, 1220mm, 1250mm |

Coil weight | 3-12ns |

Certificate | BV & SGS |

Original | Shandong,China |

Payment terms | L/C or T/T |

Delivery time | within 15 ~ 25 days after 30% prepayment |

- Q: What are the different grades of steel used in strips?

- Strips commonly utilize various grades of steel, each categorized based on their chemical composition and mechanical properties. These categories determine their suitability for different applications. Some commonly used steel grades in strips are as follows: 1. Mild steel, also known as low carbon steel, possesses a low carbon content and is easily formable and weldable. It finds application in areas that require good ductility and a smooth surface finish, like automotive components and appliances. 2. Medium carbon steel contains a slightly higher carbon content than mild steel. It offers improved strength and hardness, making it suitable for applications requiring higher load-bearing capacity, such as springs and high-strength structural components. 3. High carbon steel boasts a higher carbon content, resulting in excellent hardness and wear resistance. It is commonly used in applications demanding high strength and durability, like cutting tools, blades, and industrial machinery parts. 4. Stainless steel, containing a minimum of 10.5% chromium, exhibits excellent corrosion resistance. Stainless steel strips are widely applied in areas necessitating resistance to rust and staining, such as kitchenware, automotive trim, and architectural components. 5. Alloy steel, formed by adding various alloying elements like manganese, nickel, chromium, or molybdenum to ordinary carbon steel, enhances its strength, hardness, and overall performance. Alloy steel strips are commonly used in applications requiring high tensile strength, such as automotive gears, shafts, and fasteners. Selecting the appropriate grade of steel for a specific application is crucial, taking into account factors like strength requirements, corrosion resistance, formability, and cost. Manufacturers and engineers meticulously evaluate these factors to ensure optimal performance of the chosen steel grade in the desired application.

- Q: Can steel strips be coated with a protective layer?

- Yes, steel strips can be coated with a protective layer. This is commonly done to enhance their durability and resistance to corrosion. The protective layer is typically applied through processes such as galvanization or painting. Galvanization involves applying a layer of zinc to the steel strip, which forms a protective barrier between the steel and its surrounding environment. Painting, on the other hand, involves applying a layer of paint or coating that acts as a barrier against moisture, chemicals, and other elements that could cause damage to the steel. These protective layers not only extend the lifespan of the steel strips but also provide additional aesthetic appeal.

- Q: How are steel strips disposed of at the end of their life cycle?

- Steel strips are typically recycled at the end of their life cycle. They are collected, sorted, and sent to recycling facilities where they are processed and transformed into new steel products. This recycling process helps to conserve resources, reduce waste, and minimize the environmental impact associated with steel production.

- Q: What are the different grades of steel used for manufacturing steel strips?

- There are several grades of steel used for manufacturing steel strips, including low carbon steel, medium carbon steel, high carbon steel, alloy steel, stainless steel, and tool steel. Each grade has specific properties and qualities that make it suitable for different applications in the manufacturing industry.

- Q: What are the common widths of steel strips?

- The common widths of steel strips vary depending on the intended application and industry standards. However, some common widths for steel strips range from 1/2 inch to 36 inches or more.

- Q: What is the cost of steel strips compared to other materials?

- The cost of steel strips can vary depending on factors such as the type of steel, size, and market conditions. Generally, steel strips are considered to be competitively priced compared to other materials commonly used in various industries.

- Q: How do steel strips perform in terms of chemical stability?

- Steel strips have excellent chemical stability due to their high resistance to corrosion. This is primarily attributed to the presence of an oxide layer on the surface of the steel, which acts as a protective barrier against chemical reactions with the environment. Additionally, certain alloying elements in steel, such as chromium and nickel, further enhance its chemical stability by forming passive films that prevent corrosion.

- Q: Are steel strips suitable for the production of metal jewelry?

- Yes, steel strips can be suitable for the production of metal jewelry. Steel is a durable and versatile material that can be manipulated into various shapes and designs. However, it is important to consider the desired aesthetic and style of the jewelry, as steel may not be the best choice for delicate or intricate designs. Additionally, steel may require additional processes such as plating or coating to prevent corrosion and enhance its appearance.

- Q: What is the fire resistance of a steel strip?

- The fire resistance of a steel strip can vary depending on various factors such as the thickness and composition of the strip. However, in general, steel has a high fire resistance due to its non-combustible nature and ability to retain its structural integrity even at high temperatures.

- Q: How are steel strips processed for joining?

- Steel strips are processed for joining through a variety of methods, depending on the specific requirements of the application. One common method is welding, where the steel strips are heated to a high temperature and fused together using a filler material. This creates a strong and permanent bond between the strips. Another method is soldering, which involves melting a filler metal with a lower melting point than the steel strips to join them together. This method is often used when the steel strips have a thin or delicate coating that may be damaged by the high temperatures of welding. Additionally, adhesive bonding can be employed, where a strong adhesive is applied between the steel strips to join them together. This method is often used when a more flexible or aesthetically pleasing joint is desired. Overall, the specific process used for joining steel strips depends on factors such as the desired strength, appearance, and functionality of the final product.

Send your message to us

Prepainted galvalume steel coils RAL Color No.

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords