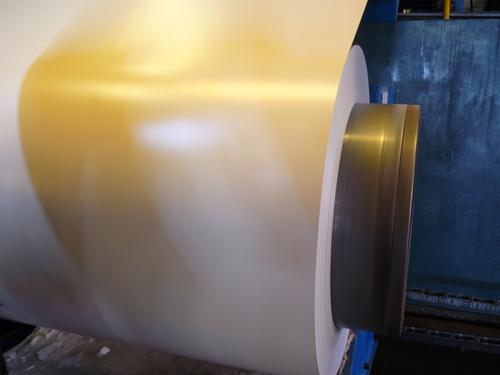

Prepainted Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Prepainted Aluzinc Steel Coil-0.47mm

With GL as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted aluzinc steel. Pre-painted Aluzinc steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

General Information Of Prepainted Aluzinc Steel Coil-0.47mm

Thickness | 0.23-1.2mm (BMT) |

Width | 900-1250mm |

Alu-zinc Coating | 50-150g/m2 |

Internal Diameter | 508mm or 610mm |

Color | According to RAL color fan |

Coil Weight | 4-8MT |

Quality | Commercial and structural quality |

Paint | Polyester paint for topside, epoxy for reverse |

Standard | JIS G 3322, ASTM A755M, EN 10169 |

Package | Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips |

Base Steel Grade | SGCC, SGCD, DX51D+Z DX52D+Z; S200GD, S220GD, S280GD,S350GD,CS,FS,SS |

Technical Data Of Prepainted Aluzinc Steel Coil-0.47mm

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Technical Data Of Prepainted Aluzinc Steel Coil-0.47mm

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Prepainted Aluzinc Steel Coil-0.47mm

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, corrugate sheet, sandwich panel for wall or roofing, facade wall,shutters and home appliance.

Packaging & Delivery Of Prepainted Aluzinc Steel Coil-0.47mm

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Delivery Detail: As customer requested

- Q: What are the different types of steel coil packaging materials used during processing?

- Some of the different types of steel coil packaging materials used during processing include steel strapping, plastic strapping, stretch film, shrink wrap, and coil covers.

- Q: describe the benifits and disadvantages of the using steel as a material for fasteners

- There are different grades of steels which can suit different application considering corrosion,surrounding atmosphere,pressure,temperature and many more. Let us take the stainless steel fasteners: 1.Resists Rust: The primary advantage to using stainless steel bolts is that they resist rusting. This makes them ideal for outdoor or marine uses, since moisture will not cause them to corrode. Rust basically eats steel and makes it weaker. A rusty, weak bolt can be a serious safety risk, because it can break under a load. 2.Clean: Stainless steel bolts are very easy to clean due to having a higher content of chromium, which creates a lustrous, mirror-like surface that is very smooth. This makes stainless steel an ideal option if aesthetics are an issue. 3.Temperature: Stainless steel has a high melting point, which makes it a good option in machines that are put through immense amounts of heat. The bolts will not fuse together, and can be unfastened when the machines need repairs. Also, in very cold conditions, steel can become brittle. By mixing nickel into the stainless steel, the metal resists becoming brittle at low temperatures. See the source link for details.

- Q: I have been searching on pots and pans, how can I find out if it's really stainless steel, someone told me if a magnet sticks to it it's real stainless steel is this true?

- Magnets stick to some stainless but not all of it, so a magnet is not a reliable indicator.

- Q: What is stainless steel coil used for?

- Stainless steel coil is primarily used in various industries for its durability, corrosion resistance, and aesthetic appeal. One of the most common applications is in the manufacturing and construction sectors, where stainless steel coils are utilized to produce a wide range of products such as kitchen appliances, cutlery, automotive parts, and architectural structures. The corrosion-resistant properties of stainless steel make it an ideal choice for applications that require resistance to moisture, chemicals, and harsh environmental conditions. Additionally, the high strength and heat resistance of stainless steel coils make them suitable for use in industrial equipment, heat exchangers, and piping systems. Moreover, the aesthetic appeal of stainless steel, with its sleek and modern appearance, is often preferred in the design and production of consumer goods, including furniture, jewelry, and decorative items. Overall, stainless steel coil is a versatile material that finds extensive usage across various industries due to its excellent mechanical properties, resistance to corrosion, and aesthetic versatility.

- Q: How are steel coils inspected for color consistency using colorimetry?

- Steel coils can be inspected for color consistency using colorimetry by measuring the color of the surface using a spectrophotometer. This device analyzes the reflected light and provides objective and precise color data. By comparing the color measurements of different areas of the coil, any variations in color consistency can be identified, allowing for quality control and ensuring the desired color uniformity throughout the coil.

- Q: What are the different types of steel coil storage methods?

- There are several types of steel coil storage methods, including stacking coils vertically, using coil cradles or saddles, utilizing coil racks or frames, employing coil lifters or C-hooks, and implementing automated coil storage systems. Each method is designed to accommodate different storage requirements and ensure the safety and efficient handling of steel coils.

- Q: Can i use steel shot in a remington 870 wingmaster full choke 30 inch barrel. the shotgun is in great shape and about 20 or 25 years old probably. thank you. the steel shot i have got is 12 gauge 2 3/4 in 1550 velocity 1 1/16 oz 2 shot winchester xpert high velocity steel shot

- The biggest problem is the FULL choke on the end of the barrel. Steel pellets are harder than lead, so they find it hard to squeeze through the tight full choke. If you do it, you WILL either bulge or crack the muzzle end of the barrel. That is a fact. Newer model 870 shotguns with RemChokes can fire steel, but you have to use a lead MODIFIED choke to send a full pattern down range. Again, for the same reason I mentioned earlier - that the steel does not deform and squeeze itself through the tighter chokes as well. See photo link below at what your barrel will look like after a box of steel shot.

- Q: What materials are used to make steel coils?

- Steel coils consist primarily of steel, an alloy primarily composed of iron and carbon. The choice of steel type for coil production depends on the desired properties and applications. Carbon steel is typically the preferred option due to its strength, durability, and versatility. Additional alloying elements, like manganese, silicon, nickel, or chromium, may be incorporated to enhance specific steel characteristics or properties. To produce steel coils, the raw materials are melted, the molten steel is refined, and specialized equipment and processes are employed to shape it into coils.

- Q: How are defects in steel coils detected and resolved?

- Defects in steel coils are typically detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle testing, and eddy current testing. Once a defect is identified, it is resolved through processes like grinding, polishing, welding, or cutting out and replacing the affected area. The specific resolution method depends on the type and severity of the defect, ensuring that the steel coils meet the required quality standards before further processing or usage.

- Q: How are steel coils tested for tensile strength?

- Steel coils are tested for tensile strength through a process called tensile testing. In this method, a small sample is taken from the steel coil and subjected to a controlled force until it breaks. The force applied during the test is gradually increased until the sample fractures. The maximum force required to break the sample is measured, and this provides valuable information about the tensile strength of the steel coil.

Send your message to us

Prepainted Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords