24 Inch Square Aluminum Sheets - Precut Checkered Aluminium Plate for Door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

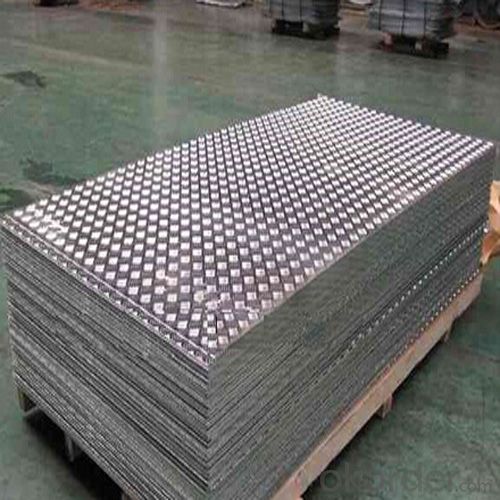

1.Structure of Precutted Checker Aluminium Plate for Door Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Precutted Checker Aluminium Plate for Door :

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and EN

3.Precutted Checker Aluminium Plate for Door Images:

4. Precutted Checker Aluminium Plate for Door Specification:

1. | Item | Aluminum coil/ Aluminum strip,1070 aluminium coil | |

2. | Standard | ATSTM B209, JIS H4000-2006,GB/T3190-2008,GB/T3880-2006, etc. | |

3. | Material | 1000 Series:1050,1060,1080,1100,1435,etc. | |

2000 Series:2011,2014,2017,2024,2A12,2A16,2A06,etc. | |||

3000 Series:3002,3003,3004,3104,3204,3030,3A21,etc. | |||

5000 Series:5005,5025,5040,5052,5056,5083,5A05,etc. | |||

6000 Series:6003,6060,6082,6083,6063,6061,etc. | |||

7000 Series:7003,7005,7050,7075,etc. | |||

4. | Specifications | Thickness | 0.01mm~20mm |

Width | 10mm~2000mm | ||

Length | or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for pharmaceutical packaging?

- Yes, aluminum sheets are suitable for pharmaceutical packaging. Aluminum is widely used in the pharmaceutical industry due to its unique properties. It is a lightweight material that provides excellent protection against moisture, oxygen, and light. This makes it ideal for packaging sensitive pharmaceutical products that require a high level of protection and stability. Aluminum sheets are also highly resistant to corrosion and have good heat conductivity, allowing for efficient heat sealing during the packaging process. Furthermore, aluminum is non-toxic and non-reactive, ensuring the safety and integrity of the pharmaceutical products. Overall, aluminum sheets are a reliable and commonly used material for pharmaceutical packaging.

- Q: What kind of material is 2A12 aluminum sheet?

- Corrosion resistance is poor, but it can be effectively protected by pure aluminum coating. It is easy to crack when welding, but it can be welded or riveted by special process. Widely used in aircraft structures, rivets, truck hubs, propeller components, and many other structures.

- Q: which has greater density 5 kg of lead or 10 kg of aluminum

- Pay attention to the terms in the questions! Under normal conditions, 5kg of lead has more density but less mass than 10kg of aluminum.

- Q: What are the necessary safety measures to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, it's crucial to wear appropriate personal protective equipment (PPE), including gloves to prevent cuts and eye protection to shield against flying debris. Ensure good ventilation to avoid inhaling dust or fumes from cutting or polishing. Use sharp tools to minimize the risk of accidents and always cut away from your body. Keep the work area clean and free of clutter to prevent slips or trips. Be cautious of electrical hazards if using power tools, and ensure all tools are properly grounded. Finally, be aware of the fire hazard potential of aluminum dust and store it safely away from ignition sources.</p>

- Q: How do aluminum sheets perform in terms of electrical conductivity?

- Aluminum sheets are known for their excellent electrical conductivity. They are highly conductive, ranking second only to copper in terms of electrical conductivity among common metals. This high conductivity makes aluminum sheets an ideal choice for various electrical applications, including wiring, power transmission, and electrical components. The low resistivity of aluminum allows for efficient transfer of electricity, ensuring minimal energy loss during transmission. Additionally, aluminum sheets are lightweight, making them a preferred material for electrical systems where weight reduction is desired. Overall, aluminum sheets offer exceptional electrical conductivity, making them a reliable and efficient choice for electrical applications.

- Q: This question asks about the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with various materials to enhance their properties such as corrosion resistance, appearance, and durability. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a dry coating that is electrostatically applied and then cured at high temperatures. 3. Paint coating, which can be either liquid or powder-based and provides a decorative and protective layer. 4. Vinyl coating, which is a plastic coating applied for a smooth, matte finish. 5. Electrolytic coating, which involves depositing a thin layer of metal onto the aluminum surface. 6. Hot-dip coating, where aluminum is coated with a layer of zinc or other metals by dipping it into a molten bath. Each type of coating serves different purposes and has unique characteristics.</p>

- Q: Can aluminum sheets be used for signage purposes?

- Indeed, signage purposes can be fulfilled by utilizing aluminum sheets. The signage industry often relies on aluminum, a highly adaptable and enduring material. Renowned for its lightweight nature, corrosion resistance, and exceptional weather resilience, aluminum is an ideal choice for both indoor and outdoor signage. By effortlessly cutting and molding aluminum sheets, one can fashion diverse sizes and designs for signs. These sheets can be painted, coated, or printed upon to exhibit logos, text, or graphics. Moreover, aluminum signs are economically advantageous and possess a prolonged lifespan, rendering them a favored option for businesses, construction sites, road signs, and various other signage applications.

- Q: How do aluminum sheets perform in terms of chemical resistance?

- Aluminum sheets generally have good chemical resistance properties. However, their performance can vary depending on the specific chemical environment and conditions. Aluminum is known to have excellent resistance to corrosion from most acids, alkalis, and organic solvents. It forms a protective oxide layer on its surface, which prevents further reaction with many chemicals. However, aluminum can be susceptible to corrosion in certain aggressive environments, such as strong acids like hydrochloric acid or sulfuric acid, and alkaline solutions with high pH levels. In these cases, the protective oxide layer may break down, leading to the degradation of the aluminum surface. Additionally, some chemicals, like mercury and certain salts, can also cause localized corrosion or pitting on aluminum surfaces. Therefore, it is important to consider the specific chemicals and concentrations that the aluminum sheets will be exposed to when assessing their chemical resistance performance. To enhance the chemical resistance of aluminum sheets, various surface treatments, coatings, or alloys can be applied. These modifications can provide additional protection against specific chemicals or environmental conditions, further improving the overall chemical resistance properties of aluminum sheets. In summary, aluminum sheets generally exhibit good chemical resistance, but their performance can be influenced by the specific chemical environment and conditions. It is advisable to assess the compatibility of aluminum with the intended chemicals and consider appropriate surface treatments or coatings if necessary.

- Q: Can aluminum sheet be used for automotive heat shields?

- Yes, aluminum sheet can be used for automotive heat shields. It is a commonly used material due to its high thermal conductivity, lightweight nature, and excellent heat resistance properties.

- Q: Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

Send your message to us

24 Inch Square Aluminum Sheets - Precut Checkered Aluminium Plate for Door

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords